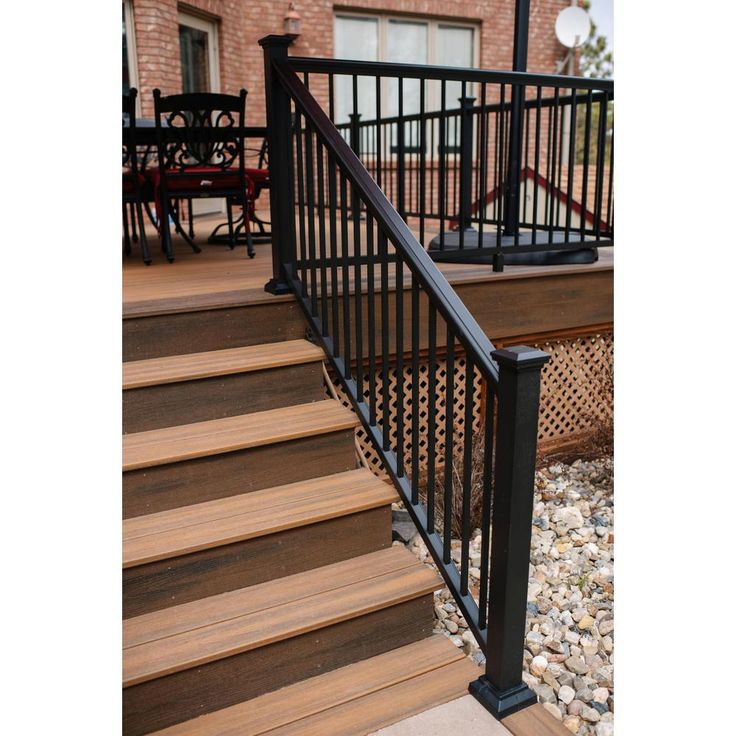

Black porch railings

Premium Quality Metal Deck Railing Systems

General Metal Railing FAQs

Why Should I Choose Metal Railing For My Deck?

Metal deck railing is exceptionally stable. Because it doesn’t absorb water like wood or composite, metal doesn’t expand or contract the same way other materials do. That expansion and contraction can cause warping, and can slowly work fasteners loose over time. Metal railing, on the other hand, stays dimensionally stable for years in all types of weather. There’s a great feeling of security in choosing a metal railing for your deck - metal railing feels sturdy and strong to the touch.

Metal deck railing systems have also become extremely easy to install. Many come with pre-welded panels that anyone can easily attach to their deck in a single afternoon. Metal is also a strong stylistic choice with multiple color options and sleek, finished looks.

What Parts Make Up Metal Deck Railing?

Deck railing is made up of (1) rails, (2) posts, and (3) infill, as shown below:

Posts are the thick, vertical pieces that give your railing strength. Rails are the long, horizontal bars - most railing systems will have a top rail and a bottom rail. Posts and rails create a rectangle; infill sits inside that rectangle. Infill can be balusters - smaller, vertical bars parallel to your posts. But railing can also use glass balusters, glass panels, or metal cables as infill. Metal railing can also use mesh panels or horizontal rods as infill instead of traditional vertical balusters.

What Different Metals Can I Choose For My Deck Railing?

We offer a range of aluminum and steel railing systems. Both are strong, durable metals, but each has its own unique strengths and weaknesses.

Aluminum is lighter-weight, for easier transport and installation. Powder-coated aluminum is also more resistant to corrosion, and in cold weather, aluminum actually gets stronger. Steel is heavier, but also sturdier - you’ll feel how solid it is when you lean against or touch a steel railing.. Steel is a rugged, strong option, with an enduring, classic look.

Finding the best deck railing material will depend on your needs and climate. Give us a call at 1-888-824-5316 and our team can learn more about your project to help recommend the best options for you.

Can I Cut Metal Railing?

Yes! As long as you have the right equipment, it’s easy to cut down rails or railing panels to fit your space. You can cut aluminum railings with a carbide-toothed saw blade. To cut steel, use a ferrous blade. Always use touch-up paint to coat the cut ends - this will help prevent corrosion.

Where Can I Buy Metal Deck Railing?

DecksDirect makes it easy to buy and plan your metal deck railing project. Here’s how:

- Real People, Real Service: We staff a team of experienced deck project planners who have personally worked with all of the systems we sell. Get expert advice as you shop, plan your project, and even as you install.

- Completely Fast: We ship 99.5% of our orders the same day they’re placed, and we reach most of the United States in three days or less.

Don’t delay your project - we’ll make sure you stay on your timeline!

Don’t delay your project - we’ll make sure you stay on your timeline! - Largest In-Stock Selection: We carry the most in-stock railing options you’ll find anywhere. Period. Get the most options to assemble your dream deck without being limited to a few basic in-stock options.

You can always order online, or you can call us during regular business hours at 1-888-824-5316 and talk to a trained deck project planner. We look forward to hearing from you!

Will Metal Deck Railing Rust?

Metal deck railings are corrosion-resistant - and you can keep rust away by cleaning your rails a few times a year. If you live in a wet climate or are installing railing near a pool, lake, or ocean, powder-coated aluminum will be the most corrosion-resistant option.

Will Metal Railings Get Hot In the Sun?

Like all deck railing materials, metal can absorb heat in direct sunlight and get hot to the touch. The biggest factor determining how hot your railings will get is color: dark-colored railings absorb more heat than light-colored ones. For that reason, if your railing is in direct sunlight or in an especially hot climate, we’d recommend looking into our metal railings with white or light-colored options. That includes Fortress AL13, Westbury Tuscany, Westbury Riviera, AFCO Pro, Century Aluminum, Deckorators ALX, and Trex Signature Rod Rail.

For that reason, if your railing is in direct sunlight or in an especially hot climate, we’d recommend looking into our metal railings with white or light-colored options. That includes Fortress AL13, Westbury Tuscany, Westbury Riviera, AFCO Pro, Century Aluminum, Deckorators ALX, and Trex Signature Rod Rail.

Choosing Your Metal Railing

What's The Easiest Metal Deck Railing For DIY Installation?

If you're planning a DIY deck railing installation, we'd highly recommend either Fortress AL13 or Century Aluminum railing. Here are two big reasons why:

Pre-welded panels: both of those systems are panelized - that means you buy one solid railing panel that already has the top rail, bottom rail, and balusters welded together. That saves a lot of time over a larger railing project compared to other railing systems where you have to fit each baluster into the top and bottom rails individually.

Pre-bracketed posts: another way these systems save time is by selling posts with pre-attached brackets. That saves significant time in measuring and attaching brackets, and leaves you to just attach the railing panel to the posts for each section.

That saves significant time in measuring and attaching brackets, and leaves you to just attach the railing panel to the posts for each section.

What's The Most Cost-Effective Metal Deck Railing?

If you're looking to save money on your deck railing, Century Aluminum Railing provides a great low-cost option. It's also one of the easier systems to install, which can save you even more money by cutting down your installation hours.

What Color Metal Railing Should I Choose?

When picking out a railing color for your deck, you should consider the colors of your house and decking, but also what you want your railing to do for your deck view.

You can try to match colors already present in your deck area: for example, white railing is a great visual accent to your deck if your house has white siding or a lot of white trim. But you can also look for different accenting colors: a trendy gray deck area will go great with sleek black railings.

If you have a view of nature, bronze railings have an amazing feature: the organic bronze color tone virtually disappears into the background, opening up your deck view.

These are just a few examples of how different railing colors can add different features to your deck. To pick a railing perfectly tailored to your space and priorities, give our team a call at 1-888-824-5316 to walk through all the options.

Installing Metal Railing

How Hard Is It To Install Metal Railing?

Most metal deck railing has become surprisingly easy to install, even for budding DIYers or deck project rookies. Many metal rail systems come in pre-welded panels that make installation a breeze. These include Fortress Al13 Home, Fortress FE26 and Fortress AL13 Pro.

What’s The Easiest Metal Deck Railing To Install?

Metal deck railing systems with pre-welded panels and pre-bracketed posts will be the easiest to install: that includes the Fortress Al13 Home, Fortress FE26 and Century Aluminum railing lines.

You can always give our team a call at 1-888-824-5316 for free recommendations on the best railing options that you’ll be able to install based on your experience level with home and deck projects. We love to help connect customers with the perfect project for them.

We love to help connect customers with the perfect project for them.

Metal Railing Maintenance

How Do I Clean Metal Railings?

Metal railings are extremely low-maintenance, and keeping them clean is a breeze.

How to clean:

- Step 1: In a bucket, mix warm water and a pH neutral detergent. (PH neutral detergents include mild dish soaps like Dawn, Palmolive, or Ajax).

- Step 2: Use your cleaning mixture and a soft cloth, sponge or non-abrasive brush to wipe down the surfaces of your railing.

- Step 3: Rinse the cleaning solution off the railing with clean, fresh water. Take care not to leave the cleaning solution on the railing for more than 30 minutes before rinsing.

It’s that easy. You only need to clean your railings a few times a year, though we’d recommend more frequent cleaning if your railing is exposed to saltwater or pollen.

Aluminum & Composite Deck Railing

Skip to contentRailing

Browse our high-performance metal and composite deck railing systems to find the right finishing touch for your outdoor living space. With profiles ranging from classic to contemporary, our railing gives your decking masterpiece the frame it deserves.

With profiles ranging from classic to contemporary, our railing gives your decking masterpiece the frame it deserves.

- Clear filters

Color

- BLACK

- BROWN

- WHITE

Pricing

- $

- $$

- $$$

- $$$$

Material

- Aluminum

- Composite

Style

- Modern

- Traditional

- Transitional

Surface Finish

- Gloss

- Matte

- Metallic

View details

$0. 00

00

Color:

Sample:

Select a sample size:

Sample added to cart

No samples are available. Visit your local dealer or retailer to see this product up close.

Discover Ready-to-Customize RailingExplore the TimberTech metal and composite railing portfolio in this inspiring guide. Learn how to customize your railing components, get design ideas, and find the right rail for your backyard build.

Download Guide

Estimate Your Project CostsNeed to estimate the cost to build a deck? Calculate for factors like deck size, materials, and add-ons like railing with this easy-to-use tool.

Calculate Cost

Imagine the Possibilities

Railing is just one part of your seamless outdoor living space. Explore completed projects to see how everything comes together.

View Gallery

Ready to Go Against the Grain

®?Let TimberTech be your guide.

Connect With A decking expert

This site uses cookies to ensure you get the best experience. LEARN MORE GOT IT

Privacy & Cookies Policy

Scroll to Top

Stair railing | Forging Odessa

Which railing to choose for the house?

If you are a blacksmith or welder and produce wrought iron railings, then you need to know everything about their types and see what your colleagues are doing.

If you are a customer for wrought iron railings, you need to know what types exist, what the market offers and what can be ordered.

Wrought iron railings have a presentable appearance, are reliable and durable. The structures successfully solve the problems of interior and exterior design of buildings and sites. nine0005

Original and modern metal railings set the decorative direction and harmoniously connect the elements of the environment into a single whole.

Types of wrought iron railings

Blacksmiths create a wide range of beautiful wrought iron railings. Enterprises offer both exclusive premium products and welded structures made from prefabricated elements.

Enterprises offer both exclusive premium products and welded structures made from prefabricated elements.

The customer provides their products made in various styles and directions. The variety of colors, line shapes and sizes is amazing. nine0005

The client has the opportunity to choose a standard solution without any special decorative frills.

Designers are ready to offer spectacular options, such as white or patina railings with ornate patterns and ornaments as decoration.

Stair railing

The most common type of railing is the stair construction.

Wrought iron emphasizes the design, acts not only as a guarantee of safety and an obstacle to falling, but also an interesting element in the interior or exterior of the spiral staircase. nine0005

Spiral stair railing

A spiral staircase is an indispensable solution for rooms with a small area and it is necessary to maintain a certain style of construction. This type is a decorative and functional structure. These advantages make spiral staircases popular with customers.

These advantages make spiral staircases popular with customers.

An interesting addition to the spiral staircase will be openwork forged railings that will emphasize the lightness and airiness of the railing design in the house. nine0005

When installing wrought iron railings, you should first of all take care of safety and only then of design. For houses where people live, the design must exceed the standard dimensions by more than 1 meter 20 centimeters. It is also desirable to have dense patterns without large gaps.

When choosing a railing to be located in the house, customers most often choose calm tones. Designs in black or white are the best option. The design is developed in accordance with the environment. nine0005

Wrought iron porch railing

Outdoor railing should reflect the overall style of the home or building. In addition, street structures should be treated with high quality after

production, as the impact of weather factors can adversely affect the appearance of the product.

Outdoor wrought iron railing will demonstrate the original taste of the owner and attract the attention of others.

Forged railing on the porch is the face of its owner. Therefore, special attention should be paid to the design of the porch. On the porch, beautiful chic railings will look unsurpassedly a wonderful addition to wrought iron railings is a canopy or canopy. Also made of metal by artistic processing. nine0015 An interesting solution is a porch with a roof decorated with wrought iron railings.

How high should the balcony railing be?

The height of balcony railings should be at least 1.1 m (1100 mm), and if there are children in the house, then preferably at least 1.2 m (1200 mm). The distance between the individual vertical elements must be no more than 12 cm (120 mm).

How much does a stair railing cost?

The price of simple railings is from 1500 UAH per 1 linear meter. Forged railings on the second floor start from 2500 UAH per 1 linear meter. nine0005

nine0005

How to make a railing on the porch?

The best porch railing material option is stainless steel. Stainless steel railings are maintenance free. If you want a wrought iron porch railing, use quality paint so that the railing doesn't rust and doesn't need to be touched up every season.

Metal porch railing

Contents

- Advantages and disadvantages of metal railings

- Materials and methods for making railings

- Prefabricated Porch Railing

- Welded Porch Railing

- Wrought Iron Porch Railing

- Cast Railing

- Metal Railing Requirements

- Conclusion The porch is a very important part of any building façade. Its appearance allows you to create a first impression about the building itself, as well as about its owners. Railings are an indispensable element when decorating a porch. In addition, thanks to this element, it becomes possible to support when descending and ascending stairs.

- high strength characteristics. For the porch, this is very important, since they are constantly on the street and are affected by strong winds and various precipitations; nine0064

- compatibility with any buildings in the architectural sense. Metal elements are perfect for the restoration of an existing outdated porch;

- the ability to combine with other different materials. When designing metal elements, you can use a combined option by combining metal with concrete, wood or polycarbonate;

- increased resistance to decay;

- resistance to temperature changes;

- moisture resistance; nine0064

- resistance to mechanical damage;

- metal does not lend itself to deformation changes.

- high cost, often a very important selection criterion;

- need for additional processing. It includes a coating with means that protect against corrosive effects.

- Aluminum porch railing. They have plasticity, and due to this they are not able to perceive high loads. The aluminum railing shown in the following photo is great for indoors.

They do not require special care and are not susceptible to corrosive attack. And from this material you can create a design of various shapes and colors. nine0015

They do not require special care and are not susceptible to corrosive attack. And from this material you can create a design of various shapes and colors. nine0015 - Iron is a versatile material. Most often used in industrial production. But, pay attention to the following photo, this metal can also be used at home, for example, in the manufacture of railings. The disadvantages of this metal include the difficulty in processing and assembling the structure. It also needs to be treated from time to time with anti-corrosion agents and painted quite often.

- Cast iron, very commonly used for outdoor railings. Especially, as seen in the following photo, it is suitable for elements produced in the old style. Indoors it is used very rarely, because it has a very massive appearance. nine0015

- Steel railings are resistant to temperature extremes. Very often, ground steel railings are used for the porch. Pay attention to the following photo, this material has good wear resistance, practicality, and also does not require special care.

Also, stainless steel is especially popular, the main advantage of which is resistance to corrosion.

Also, stainless steel is especially popular, the main advantage of which is resistance to corrosion.

- ease of assembly and subsequent installation;

- low cost;

- light weight. nine0075

- protected with a polymer coating;

- anodized aluminum railing;

- steel, chrome plated.

- semi-automatic.

With such a connection of elements, a significant drawback arises - the manifestation of a large number of splashes;

With such a connection of elements, a significant drawback arises - the manifestation of a large number of splashes; - argon arc. With this connection, the weld is very neat. It is also very easy to process afterwards.

- optimal height ranges from 90-100 cm;

- for children's institutions, the height is reduced to 50 cm;

- the gap between the installed posts should be about 60 cm;

- when attaching the handrail to the wall structure, there must be a gap of 10 cm; nine0064

- handrails must be smooth and always solid;

- handrails must be 30 cm longer than the staircase itself, and their end must be rounded;

- ability to freely bear a load of 100 kg at an interval of one meter.

Learn more

nine0005

nine0005

Pros and cons of metal railings

There are many materials that railings can be made from. It can be wood, stone, concrete and many other building materials. But metal is more popular in such cases. And this is not surprising, since metal porch railings have a lot of advantages:

There are also disadvantages that should not be forgotten when choosing this material:

Tip! In order to eliminate the need for constant metal treatment with coloring agents, it is worth paying attention to the railings that have a layer of a special galvanized coating. nine0005

An example of such a railing can be seen in the following photo.

Materials and methods for the manufacture of handrails

So, the choice of material for the handrail fell on the metal. But now you need to decide on a more specific type of metal. There are several types suitable for the manufacture of railings:

In addition, metal railings, depending on the type of production, are divided into the following types. nine0005

Prefabricated porch railing

This type includes elements made of aluminum or steel. Steel structures after complete assembly are painted, but aluminum structures are treated with a special substance that complements the protective functions.

Aluminum elements have a lot of positive qualities:

Depending on the treatment with a protective coating, railings of this type are also divided into several main types:

Welded railings

Welded railings are made from ferrous metal or steel. This design will last for a very long time for the porch. But this is not their only merit. If the metal is properly processed and cared for, then this is also a very attractive element in the overall design of the porch. In order to make stainless steel elements, the so-called cold bending method is used, shown in the following photo, in which the metal is bent in accordance with the specified parameters. Often, when using this type of material, various ornaments with geometric shapes are made. nine0005

This design will last for a very long time for the porch. But this is not their only merit. If the metal is properly processed and cared for, then this is also a very attractive element in the overall design of the porch. In order to make stainless steel elements, the so-called cold bending method is used, shown in the following photo, in which the metal is bent in accordance with the specified parameters. Often, when using this type of material, various ornaments with geometric shapes are made. nine0005

A disadvantage of welded structures is the susceptibility of the metal used to corrosive attack. Therefore, it requires periodic staining.

Stainless steel does not have this disadvantage. The service life of these elements can reach several tens of years. For them, there is no need for additional processing and painting. If necessary, repair work can be carried out even with your own hands. The steel surface needs only polishing, grinding or satin finish. nine0005

Welded railings can be produced using two types of welding:

Handrails are fastened using a hardware assembly or a special adhesive.

Wrought iron porch railing

This type of porch railing belongs to the classical style. For several centuries, this type of metal products has enjoyed enviable popularity. Forged metal elements for the porch are perfect for buildings made of various materials.

These railings are very difficult to make by hand. Such work is only possible for blacksmiths. But without much difficulty, you can independently draw up drawings of the future design, according to which it will be easy to implement the idea with the help of a qualified craftsman. You can also purchase a ready-made product, which requires only self-installation on the porch. nine0005

Cast railings

Sample preparation is required before manufacturing these railings. With the help of it, a form for pouring metal is made. The metals that are used for such railings are brass, cast iron or bronze. The metal is melted and poured into a pre-prepared mold. After the element has completely solidified, additional processing will be required. Such enclosing structures have such positive characteristics as a long service life, a high strength index and a large selection of design features. nine0005

With the help of it, a form for pouring metal is made. The metals that are used for such railings are brass, cast iron or bronze. The metal is melted and poured into a pre-prepared mold. After the element has completely solidified, additional processing will be required. Such enclosing structures have such positive characteristics as a long service life, a high strength index and a large selection of design features. nine0005

Requirements for metal railings

The main requirements for enclosing structures for stairs fully affect the safety of their operation: