Average thread count for bed sheets

Best Thread Count for Sheets

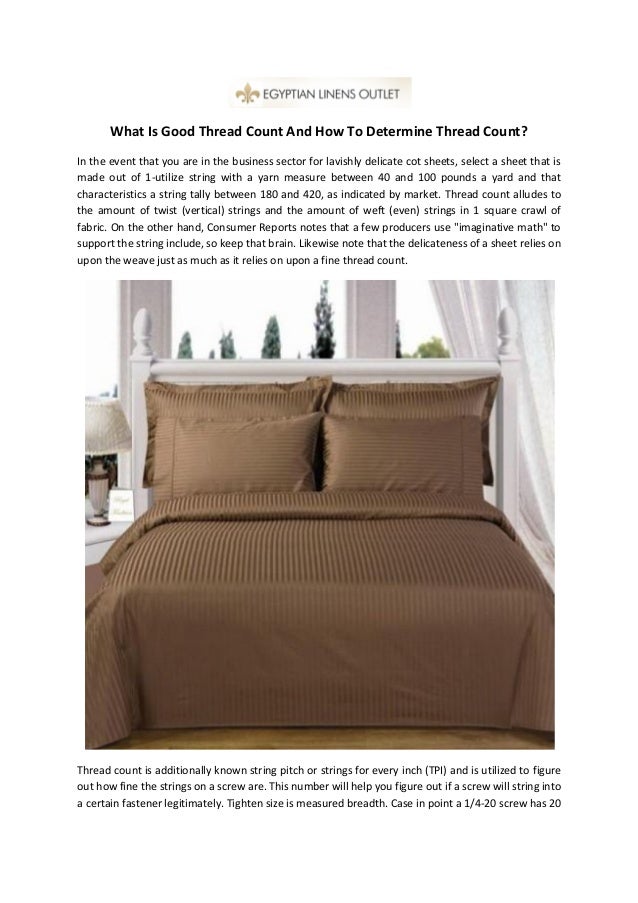

If you’re shopping for new sheets, you’ll see a variety of terms used that may be unfamiliar to you. A popular quality rating is thread count, which refers to the density of threads used in a square inch of fabric.

What does thread count actually mean? Does it matter? If so, what is the best thread count for sheets? We’ll break down each of these topics and more.

What Does Thread Count Mean?

Thread count is a measure of the number of threads woven into one square inch of fabric. Essentially, it’s a measure of how tightly woven a fabric is.

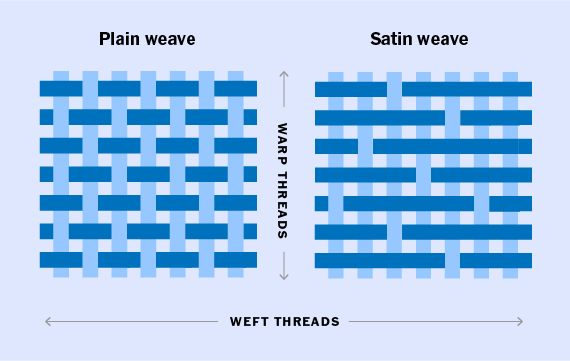

It is calculated by adding together the numbers of lengthwise (warp) and widthwise (weft) threads within a certain area. For example, a cotton sheet with 100 warp threads and 100 weft threads in each square inch of fabric would have a listed thread count of 200.

Thread count is used as a rough indicator of the softness and feel of a fabric. It’s also used heavily in marketing to imply that a specific product is of a higher quality than competing sheets. While this is all true to a certain extent, thread count is far from the only consideration when it comes to the overall quality of a set of sheets.

When thinking about the best thread count for sheets, it’s important to remember an age-old saying: Quality over quantity. The quality of the yarns or threads used is often more important than the quantity of threads, or thread count.

What is the Best Thread Count for Sheets?

Quality, comfortable sheets can be found with thread counts ranging from 200 to 800 and beyond. There’s no magic number that is the perfect thread count. That being said, there are generally acceptable ranges for various kinds of quality sheets.

At a minimum, look for sheets with an advertised thread count of 200. Anything lower than likely won’t feel as soft, and may result in a less comfortable sleeping experience.

The type of fabric and its weave makes a difference in the best thread count. Percale is also known as “plain weave” with a simple one over, one under pattern, so average-quality percale sheets may be around 180-200 thread count. By contrast, a sateen weave has a more tightly woven pattern, so average-quality sateen sheets will be closer to 250-300.

By contrast, a sateen weave has a more tightly woven pattern, so average-quality sateen sheets will be closer to 250-300.

Here are some basic ranges of high-quality thread counts for sheets of various materials:

- Cotton: 200-400

- Egyptian Cotton: 300-400

- Percale Weave: 200-400

- Sateen Weave: 300-600

- Bamboo: 300-500

- Linen: 80-140. Thread count is less of a useful indicator for linen sheets and rarely listed. Avoid higher thread counts for linen sheets.

Keep in mind that certain materials are not measured using thread count. Some notable ones include:

- Silk: Measured in momme. Momme is a measure of weight that looks for the number of pounds in a piece of silk that is 45 inches by 100 yards. Look for silk sheets around the 17-22 momme range.

- Microfiber: Measured in grams per square meter (GSM).

Look for microfiber sheets in the 90-120 GSM range.

Look for microfiber sheets in the 90-120 GSM range. - Flannel: Measured in GSM. Durable, heavyweight flannel sheets are in the 170+ GSM range. Lighter flannel sheets will be less durable, but lighter and more breathable.

- Jersey: Jersey is a type of knit that often uses cotton, but not always. The weight may vary somewhat depending on the material used. Many jersey cotton sheets are around 150 GSM.

Of course, remember that thread count is not an end-all, be-all measurement. The quality of the yarns, the manufacturer’s production process, the weave type, and many other factors all contribute to the performance of a set of bed sheets.

For best results, look for sheets from a trusted manufacturer. Read bed sheet reviews, research material quality, and consider thread count as just one of the many factors to keep in mind. If you’re looking for quality sheets, check out our bed sheet buying guide for our own recommended products.

Is a Higher Thread Count Better?

Sheets with a higher thread count are generally more expensive, and are marketed as being higher quality. As we’ve discussed, however, a higher thread count can be an indication of higher quality, but that’s not necessarily the case.

It is true that a sheet set with a thread count of 400 will usually feel better than a comparable set with a thread count of 200. However, that’s assuming that the quality of yarns used, the craftsmanship, and the weave are all the same for both sheet sets.

Looking for sheets with a reasonable thread count (200-600 for most styles) will typically produce the best results. Be sure to modify your expectations somewhat depending on the material used.

Excessively high thread counts (600-800) likely won’t change much beyond the price tag. Very high thread counts are typically very similar in terms of feel and performance to high-quality fabrics with lower counts. Trying to pack too many threads into a fabric can sometimes stifle airflow, resulting in a heavier, warmer feel.

Shoppers should be wary of extremely high thread counts, such as 900 or more. Often, this is an indication of low-quality sheets, as the manufacturer is likely using some sort of trick to disguise the true quality of the product.

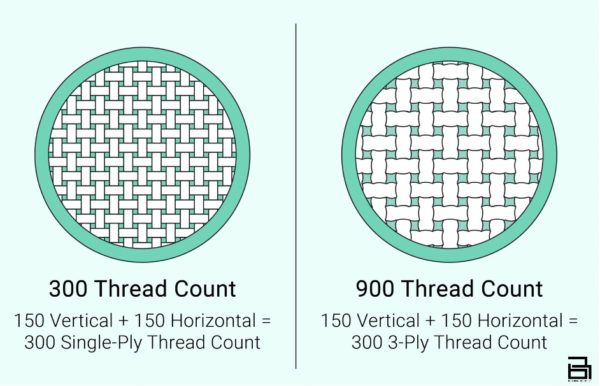

One common tactic to artificially inflate the thread count is to use double- or triple-ply threads, which are usually of a lower quality. As each thread technically has two or three fibers, they are counted two or three times when it comes to the thread count. This could result in a sheet set with a thread count of 900 that’s actually of a lower quality than a similar set with a thread count of just 300.

- Was this article helpful?

- YesNo

What’s a Good Thread Count for Sheets?

We independently review everything we recommend. When you buy through our links, we may earn a commission. Learn more›

Real Talk

Advice, staff picks, mythbusting, and more. Let us help you.

Share this post

We’ve spent hundreds of hours scrutinizing and sleeping on dozens of cotton sheet sets, and we know from experience that manufacturers sometimes game the thread counts, doubling the numbers to make their sheets seem more luxurious. According to the many experts we’ve interviewed, really good sheets—the ones that feel soft and wear well after years of use and washing—generally have thread counts ranging from 200 to 600, depending on whether they’re percale or sateen. But honestly, thread count isn’t the most important thing to consider. A lot of other factors—such as the type of cotton and yarns the sheets are made from—are more important in picking a soft, long-wearing set.

We spoke with five experts for this piece, and they all agreed that thread counts are an important indicator of quality sheets, but that you should be suspicious of numbers that are too high or too low. Manufacturers calculate thread count by adding up the vertical warp and horizontal weft yarns in a square inch of fabric. This is what the weave looks like for percale sheets (made with a plain weave) and sateen sheets (made with a satin weave):

Manufacturers calculate thread count by adding up the vertical warp and horizontal weft yarns in a square inch of fabric. This is what the weave looks like for percale sheets (made with a plain weave) and sateen sheets (made with a satin weave):

Preethi Gopinath, director of the Textiles MFA program at Parsons and one of the writers of our cotton sheets guide, and Shannon Maher, chairperson and assistant professor of the Home Products Development department at the Fashion Institute of Technology, both weighed in on the best thread counts for each weave:

Percale

- Gopinath said a 250 to 300 thread count was optimal (there’s wiggle room, though, as Maher said 200 was also good).

- Gopinath told us a 400 to 500 thread count for percale could reflect a denser sheet made of fine, good-quality yarns.

Over 500 was “not necessary or likely,” she said.

Over 500 was “not necessary or likely,” she said. - Average-quality percale hovers around 180.

Sateen

- Gopinath and Maher agreed that good-quality sateen sheets ranged from 300 to 600 thread count. The number could creep higher, but this would create a very heavy sheet.

- Average-quality sateen ranges from about 250 to 300.

Judging from our testing experience, we think those ranges are pretty spot-on. In our cotton sheets guide, our favorite percale set (L.L.Bean’s 280-Thread-Count Pima Cotton Percale Sheet Set) has a 280 thread count. Both of our top sateen recommendations (the JCPenney Home 400 TC Wrinkle Guard Sheet Set from JCPenney and Cuddledown's 400 Thread Count Cotton Sateen Bedding) are 400 thread count—which, incidentally, Maher noted was her ideal number for sateen.

"Thread count really measures fabric density,” said Missy Tannen, co-founder of Boll & Branch. “Too high of a thread count means that air doesn't circulate well and you'll sleep hot." Percale thread counts are lower simply because the plain weave allows for fewer threads in a square inch. Gopinath told us this made percale lighter and cooler, which is preferable in hotter temperatures or for hot sleepers. Sateen, with its higher thread counts (that is, more densely packed yarns), tends to be softer but also heavier than percale. A higher thread count is more important for sateen because it reduces the likelihood of snagging the longer floats—the weft yarns that skim across several warp yarns.

“Too high of a thread count means that air doesn't circulate well and you'll sleep hot." Percale thread counts are lower simply because the plain weave allows for fewer threads in a square inch. Gopinath told us this made percale lighter and cooler, which is preferable in hotter temperatures or for hot sleepers. Sateen, with its higher thread counts (that is, more densely packed yarns), tends to be softer but also heavier than percale. A higher thread count is more important for sateen because it reduces the likelihood of snagging the longer floats—the weft yarns that skim across several warp yarns.

Higher-thread-count sheets are made with finer (thinner) yarns. The more yarns that fit into a square inch, the smoother, denser, and more durable the fabric. Fine yarn is also more expensive to produce, thus resulting in pricier sheets (and why densely woven sateen is more expensive than percale). Cheap sheets are made with thicker yarns, resulting in lower thread counts and a rougher feel.

The best yarn is made from long-staple or extra-long-staple (ELS) cotton; longer threads of cotton fiber in each yarn help those alternating warp and weft yarns stay smooth and flat. (You can read a longer explanation of this topic in our post about whether Egyptian-cotton sheets are worth splurging for.) That’s why long-staple cottons, including pima, Supima, and sometimes Egyptian-cotton fabrics are considered more luxurious. Maher also recommended looking for sheets made from combed cotton like our percale upgrade pick, Riley’s Percale Sheet Set; in this process manufacturers comb out debris and too-short fibers from the cotton before spinning it into yarn that can weave into softer, smoother, and more durable fabric.

Higher-thread-count sheets are made with finer (thinner) yarns. The more yarns that fit into a square inch, the smoother, denser, and more durable the fabric.

“When it comes to thread count,” Tannen said, “most people forget that the quality of threads is far more important than the quantity. " Andrés Modak, co-CEO and co-founder of Snowe, noted, “Luxury sheets aren't simply the result of a high number; first you need the highest quality yarns, expertly woven.”

" Andrés Modak, co-CEO and co-founder of Snowe, noted, “Luxury sheets aren't simply the result of a high number; first you need the highest quality yarns, expertly woven.”

When you see counts above 300 for percale or 600 for sateen, that sometimes means the manufacturers are using ply—the number of single threads twisted together in yarn—to artificially inflate the thread count, namely counting two-ply yarns as two yarns instead of one. That means a 500-thread-count sheet made with two-ply yarns might be advertised as 1,000 thread count. Single-ply yarn is more pliable and lends itself to softer fabrics than those containing multiple plies of yarn. As Maher told us, “This is a marketing effort.” She added that manufacturers raise the number to capture customers’ attention, since people tend to perceive a higher-thread-count sheet as better. In 2005 the Federal Trade Commission issued an opinion (PDF), but not a firm set of rules or guidelines, advising against this practice. But our experts noted that although many manufacturers have stopped, they do still see it happening.

But our experts noted that although many manufacturers have stopped, they do still see it happening.

“When it comes to thread count, most people forget that the quality of threads is far more important than the quantity." —Missy Tannen, co-founder of Boll & Branch

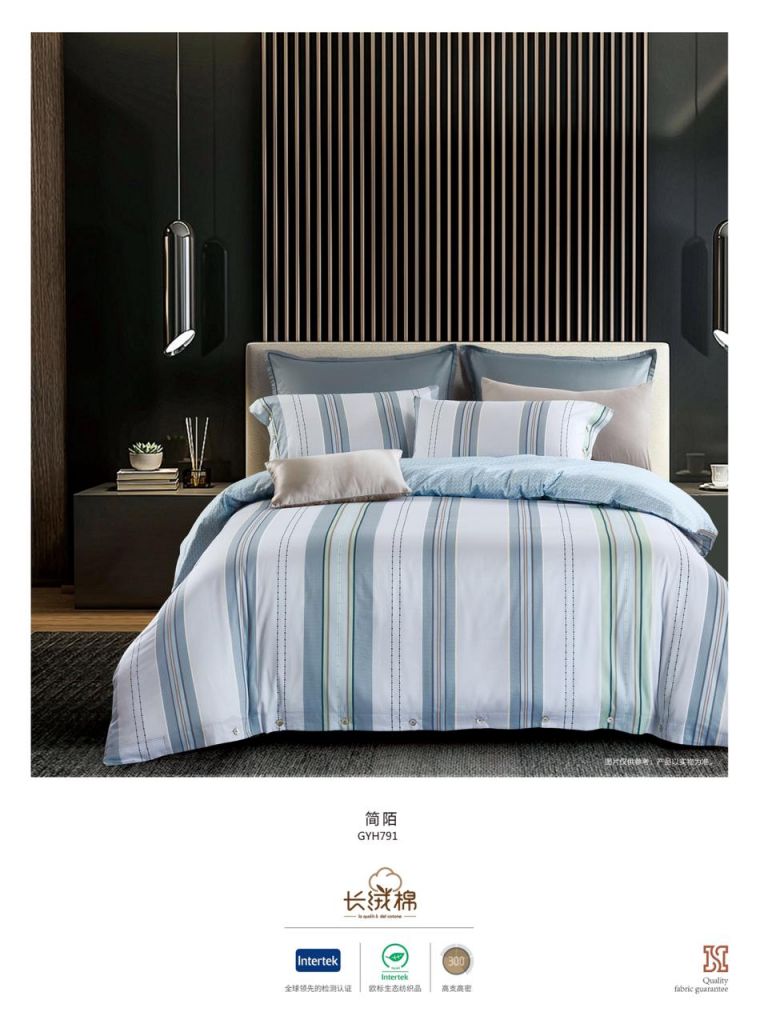

Even the print on sheets can indicate something about the quality of the fabric. Maher and Gopinath both told us that printed sheets were typically produced on lower-thread-count percale cotton to keep costs down. When manufacturers invest in a higher thread count for sheets, they don’t want to cover up that texture. “You want that to be the selling point,” Gopinath said. Print is “a cheap way of applying pattern,” Gopinath told us, an alternative to actually weaving a design into the fabric, like with a damask or jacquard.

Next time you’re shopping for sheets, instead of agonizing over the thread counts, first decide whether you want percale or sateen, and then stay within the established ranges that we covered above. Focus on the quality of the cotton instead of the thread count. As Vicki Fulop, co-founder and chief communications officer of Brooklinen, told us, “Thread count certainly matters, but it’s not the only thing that matters.”

Focus on the quality of the cotton instead of the thread count. As Vicki Fulop, co-founder and chief communications officer of Brooklinen, told us, “Thread count certainly matters, but it’s not the only thing that matters.”

Further reading

Sheets Buying Guide

by Jennifer Hunter

If you’re confused in the bedding aisle, this guide will help you choose the best year-round sheets for your bed.

Should You Spring for Egyptian-Cotton Sheets?

by Jackie Reeve

If you’re searching for the best Egyptian-cotton sheets, you’re probably looking for the wrong thing. Here’s what you need to know about good-quality sheets.

The Best Linen Sheets

by Christine Cyr Clisset

After considering dozens of linen sheet sets, and sleeping on seven sets on our own beds, we’re confident Cultiver’s Linen Sheets are the best.

The Joy (and Anxiety) of Sleeping on $2,000 Sheets

by Jackie Reeve

We tested three of the most expensive sheets sets available—ranging from $1,000 to $2,000—to see how they compared with the cotton sheets we already recommend.

Wirecutter is the product recommendation service from The New York Times. Our journalists combine independent research with (occasionally) over-the-top testing to save people time, energy and money when making buying decisions. Whether it's finding great products or discovering helpful advice, we'll help you get it right (the first time).

- About Wirecutter

- Our team

- Staff demographics

- Jobs at Wirecutter

- Contact us

- How to pitch

- Deals

- Lists

- Blog

- Subscribe to our daily newsletter

Dismiss

Bed linen density - optimal performance | TextileProfi

Manufacturers often specify one of such important parameters as the density of bed linen on sets with bed linen. Today we will talk about why this characteristic is so important for the quality of the product and what should be the density of bed linen.

What is the density for bed linen?

Before answering the question: “What should be the density of bed linen?”, It is necessary to understand what this parameter means. So, the density of linen is linear and superficial.

So, the density of linen is linear and superficial.

Linear density is a parameter that determines the number of fabric threads per square centimeter of the product. Naturally, the parameter one square centimeter is accepted in Russia, while in the world vocabulary it is one square inch.

Areal density is a parameter that determines grams of fiber per square meter of product.

Linear density of bed linen

According to its gradation, the linear density is:

- Low - up to 30 threads per 1 sq. cm,

- Below average - from 30 to 40 threads per 1 sq. cm,

- Medium - 40 to 55 threads per square cm,

- Above average - from 55 to 80 threads per 1 sq. cm,

- High - 80 to 120 threads per square cm,

- Very high - from 120 to 280 threads per 1 sq. cm.

Batiste is considered a fabric with a low density, calico with a density below average, linen is a fabric with an average density, poplin and ranfors are classified as fabrics with a density above average, high density is observed in satin and percale, and very high density in satin and jacquard .

The basis weight of bed linen

The surface density is a much less transparent characteristic. This is because for each fabric, such a characteristic as grammage per square meter is very subjective. It is impossible to say exactly how high-quality a fabric with a high surface density is. For example, if we take domestic calico and poplin from China, then the latter material has a higher linear density, and a lower surface density. At the same time, there is no doubt about the quality of the material. It's all about the method of weaving, the twisting of the threads and the density of their fit to each other.

Now let's look at the density of each specific type of material in order to determine which bedding density is best.

Coarse calico bed linen

What is calico? Coarse calico is one hundred percent cotton, high-quality and strong material. It is coarse calico that is often used to make bed linen, the interlacing of the threads of this material is carried out in a cross, as a result of which the fabric is strong and thick.

The formula for the quality of the material, including calico, is quite simple: the thinner the thread, the higher the density of the fabric, and, consequently, the higher its quality. Coarse calico is sparse, with a low density of 80 grams per square meter, medium density with parameters from 90 to 100 grams per square meter, above average density for quality kits from 110 to 125 grams per square meter, high density with parameters from 130 to 160 grams per square meter. The optimal density for coarse calico is 100-125 g/m2. In this case, more is not better, since the high density of the calico suggests a very coarse fabric that is difficult to use for bedding and home use.

Why choose calico bedding? It is inexpensive, practical, functional. If you choose a kit for everyday use, not obsessed with the softness of products, then calico is a great choice for you.

Ranfors bed linen

Ranfors is a “brother” of coarse calico, it also consists of 100% organic cotton. However, the difference lies in the density - it starts at 120 grams per square meter. Another difference is the raw material - it is made from the best varieties of cotton, so the fabric is considered elite. The quality of raw materials translates into the fact that at the output the material “rolls” less, it turns out to be pleasant to the touch and beautiful from an external point of view.

However, the difference lies in the density - it starts at 120 grams per square meter. Another difference is the raw material - it is made from the best varieties of cotton, so the fabric is considered elite. The quality of raw materials translates into the fact that at the output the material “rolls” less, it turns out to be pleasant to the touch and beautiful from an external point of view.

Ranforce also uses high-tech processes that process cotton. As a result of this, the fibers become softer, stronger, and shiny. Such a fabric is well dyed and is hygroscopic, the ability to absorb moisture.

Choosing ranfors bed linen is one of the best decisions. It is really high quality, beautiful, bright and colorful. The fact is that although it is not cheap, you pay for quality.

Biomatine bed linen

Biomatine is another cotton derivative, 100% cotton. Its density is the same as that of the ranforce, 120 grams per square meter. It is this material that is distinguished by the fact that the fibers of the fabric are processed with a special composition containing hypoallergenic components. Thus, this material is an indispensable option for bedding for children or people with sensitive skin.

Thus, this material is an indispensable option for bedding for children or people with sensitive skin.

Poplin bed linen

Poplin threads are twisted in a linen type, but unlike coarse calico, threads of different thicknesses are used - the basis is made up of thin threads, and the layering is carried out from more solid threads. It is thanks to this that the poplin surface has an interesting look with scars. The fabric is soft and pleasant to the touch, its average density is from 110 to 120 grams per square meter.

If you want to choose underwear made from poplin, you can trust domestic producers, because the quality of Russian poplin is one of the most recognized in the world.

Satin bed linen

Satin, unlike all the fabrics we talked about above, has a completely different weave of threads - twill weave and double twist of threads are used in its manufacture. From an external point of view, satin has a smooth surface, similar to silk, and from the wrong side it is more matte. The higher the density of threads in satin, the more it looks like silk. The average density of this fabric is 110-120 grams per square meter. However, there is also the so-called deluxe satin on the modern goods market, whose density is 130 grams per 1 sq.m.

The higher the density of threads in satin, the more it looks like silk. The average density of this fabric is 110-120 grams per square meter. However, there is also the so-called deluxe satin on the modern goods market, whose density is 130 grams per 1 sq.m.

Silk bed linen

Truly the most expensive raw material for bed linen. It is incredibly beautiful and luxurious. The density of this material is not measured in grams per square meter, but in special Mommi units. The more of these units, the correspondingly greater density is observed in the tissue. For silk bed linen, the best density is 19 mm.

Linen bed linen

If you are a supporter of an eco-friendly lifestyle and prefer natural materials, then linen bed linen should become an indispensable attribute of your lifestyle. This material is deservedly considered one of the most natural and natural, no chemical additives are used in its manufacture, especially if the linen is not dyed. This bed linen is ideal for people with sensitive skin, for people suffering from allergies, as well as for those who are prone to developing skin problems.

As for the density of linen bedding, it usually ranges from 125 to 150 grams per square meter. A good set of natural linen is not cheap, but will last you quite a long time. In addition, linen is unpretentious in care, absorbs moisture well and fits perfectly into almost any bedroom interior.

Bamboo bed linen

Not so long ago, bamboo was widely used among the materials for linen sets. It was quickly appreciated for its appearance - iridescent and smooth, as well as for its softness and pleasantness to the body. However, the most important advantage of bamboo is that it belongs to the category of antiseptics. In addition, bamboo bedding perfectly absorbs moisture and odors.

The density of bamboo is quite high, which affects its excellent quality. However, the main disadvantage of products made from this material is the difficulty in care - this fabric is really picky.

The choice of bed linen is not an easy task, here every parameter is important. Knowing what weight is best for each fabric can make this choice a little easier. Or at least you'll be better versed in the world of bedding sets.

Knowing what weight is best for each fabric can make this choice a little easier. Or at least you'll be better versed in the world of bedding sets.

Selection of bed linen. Types and density of weaving threads

The quality and strength of bed linen depend not only on the composition of the fabric, but also on the method of weaving threads and density of fabric (this is the number of threads per 1 cm2).

Interlacing of threads

This is the order of successive arrangement (weaving) of threads with each other in accordance with weave report , which form fabric, curtains, knitwear, etc., with a characteristic weave for this weave appearance, structure and properties.

Any fabric consists of two threads perpendicularly interlaced:

- warp threads , which are located along the fabric;

- weft threads that run across the fabric.

Weave pattern is the minimum number of threads required for a finished weaving pattern.

The sequence in which the threads are intertwined creates a particular pattern on the fabric and gives it different properties. The number of patterns of weaving weaves is great and they are divided into simple (basic) and complex .

to simple weavers include linen, sargot, satin and satin etc.

to Complex interweaving include two -leaf, two -layer, peak, pile, loop, re -rustic, etc.

The most common one is 901 weave , it has a uniform surface on both sides of the fabric - outer and inner.

In this weave, the weft thread overlaps one warp thread (see figure in the Coarse calico section). Such weaving is carried out from thick threads and it is very frequent, it is distinguished by a characteristic pattern - threads running crosswise, as in a checkerboard pattern. With this weaving The threads are held together the strongest , so the fabric will be the most durable. But due to private thread kinks, it will also be the most rigid.

But due to private thread kinks, it will also be the most rigid.

This weave is used for the production of fabrics - chintz, coarse calico , batiste, percale, many underwear and dress fabrics, as well as for fabrics made of natural silk (for example, crepe de chine, crepe georgette), rayon, poplin , taffeta, etc.

Twill weave gives diagonal (oblique) stripes (rib) on the fabric. In this type of weave, the weft thread overlaps 2 and 3 warp threads or vice versa. Twill weaves include twill, boston, etc.

Satin weave (or satin) gives the fabric a smooth, shiny finish. In these fabrics, one weft thread overlaps 4-8 warp threads (see the picture in the "Satin" section), i.e. the threads are intertwined with the threads of another row not through one, but with significant gaps.

The satin weave is distinguished by a characteristic pattern - a barely visible diagonal on a smooth fabric . Due to the sparser intersection, the fabric is outwardly dense, smooth and shiny, and to the touch is even, soft and flexible . This fabric is even more resistant to abrasion. But due to the complexity of production, it is also more expensive. The more twisted the thread, the brighter the shine.

Due to the sparser intersection, the fabric is outwardly dense, smooth and shiny, and to the touch is even, soft and flexible . This fabric is even more resistant to abrasion. But due to the complexity of production, it is also more expensive. The more twisted the thread, the brighter the shine.

Coarse calico

The most famous type of fabric for bed linen. Thick cotton fabric dense plain weave.

Coarse calico - matte fabric, it does not have a sheen, unlike satin.

There are several varieties with a density of 100 - 145 gr/sq.m. The higher the density (and the thinner the thread), the higher the quality of the fabric.

Coarse calico according to GOST is a fabric with a density of 145 g/sq.m. However, in order to make the linen as light and soft as possible, an average weave density is used and its density is 125 gr./sq.m.

There are several types of calico:

- coarse calico (undyed and unbleached) - this is the most dense type of calico.

It has a creamy tint and is most often used for upholstery and workwear.

It has a creamy tint and is most often used for upholstery and workwear. - bleached calico (or linen) - thinner and softer than harsh. Bedding is made from it.

- plain dyed calico - when the material is dyed in one color. In its structure, it corresponds to bleached calico. Linings for suits, table and bed linen are mainly sewn from such coarse calico.

- printed calico - the fabric has a color pattern. Bed linen, children's and adult things to wear are sewn from such coarse calico.

Coarse calico bedding sets are very practical, do not require special care and are quite cheap, withstand a large number of washes and are popular with buyers.

Satin

Shiny and soft cotton fabric satin weave .

The satin weave fabric is highly resistant to abrasion, glides well, has a flat and smooth surface. Satin is pleasant to the touch and is characterized by good softness and elasticity.

Linen made from it is durable and can withstand a large number of washes - 200-300, and only after a long time the material begins to fade a little.

This is a durable fabric with a high density of 120-140 threads/cm, which is practically wrinkle-free.

There are several types of satin: coupon, mako satin, satin jacquard.

Coupon satin is a type of satin and is distinguished by an individual pattern on the pillowcases, and a unique pattern on the duvet cover, they are not sewn from a stamped fabric with a repeating pattern, but from a fabric, the pattern on which is designed specifically for a certain size of the product. Each coupon duvet cover is like an art painting .

Mako satin is a type of satin, is made from high quality Egyptian cotton . Mako-satin differs from satin in the ratio of interlaced threads - per 1 square centimeter: 50 threads in the longitudinal direction, 31 threads in the transverse direction. This ratio makes it possible to make the fabric especially durable and at the same time thin, light and smooth, silky in appearance and to the touch. This is a very beautiful, comfortable, thin and at the same time dense fabric, it is easy to wash, requires a minimum of ironing. Plus, the fabric is breathable.

This ratio makes it possible to make the fabric especially durable and at the same time thin, light and smooth, silky in appearance and to the touch. This is a very beautiful, comfortable, thin and at the same time dense fabric, it is easy to wash, requires a minimum of ironing. Plus, the fabric is breathable.

Satin jacquard - intricate, intricate, dense weave with a relief pattern. The design on the fabric appears by complex weaving performed on a loom. This loom was invented in 1801 by the French weaver and inventor J. M. Jacquard. The jacquard loom is called one of the most advanced machines ever made. The basic principles of the jacquard loom have remained virtually unchanged, with the exception of an increase in the speed of work and the use of modern computer technology. The uniqueness of the jacquard mechanism lies in the ability to use hundreds of threads on the loom to create patterns of any complexity.

Jacquard satin bedding is more often sewn either in one color, or using two colors, but one tone.

The fabric is particularly durable. The printed pattern makes the fabric luxurious, so bed linen made from this material will be an ideal gift.

Poplin

Dense calico-like fabric, plain weave , is made, as a rule, from cotton, less often woolen, silk and synthetic threads.

The technology by which poplin is produced is the alternation of a thin dense warp of threads with a coarser and rarer transverse weft, due to which the fabric is obtained in a small transverse scar.

Despite the high density, the fabric is soft and pleasant to the touch. Shirts are often made from poplin.

Weave density

The fabric quality also depends on the weave density of the threads, i.e. on the number of threads per square centimeter of fabric.

The higher the thread count, the higher the quality of the fabric. At normal tissue density, about 40-50% of its volume is occupied by threads.

The classification looks like this:

· low density (20-30 threads per 1 cm 2 ),

· below average (35-40 threads),

· average (50-65 threads),

· above average (above average 65-80),

high (85-120),

very high (130-280).