Refurbishing cabinet doors

How to Refinish Cabinets and Give Your Kitchen a New Look — Bob Vila

Photo: istockphoto.com

Refinishing cabinets is one of the best ways to give your old, ho-hum kitchen a fresh new look, and it can make a big difference in the way you feel about a space. After all, having expensive cabinets hanging on your kitchen walls doesn’t mean much if you don’t like the color. That’s why many homeowners think about refinishing cabinets with a stain color of their own choosing. It is a big job, but there’s an even bigger payoff.

Before you begin refinishing your cabinets, however, it’s best to do a little detective work. You need to know what materials you’re working with to see if the job is even possible. But, with that research and a lesson on how to refinish cabinets, it’s possible to give a kitchen a serious upgrade.

Safety Considerations for Refinishing Kitchen Cabinets

Before we go too far, it’s important to consider the safety and environmental concerns involved with kitchen cabinet refinishing. You’ll probably need to employ harsh chemicals and create a lot of airborne particulates, so safety does matter.

First, make sure to refinish the cabinets in a well-ventilated area. If the cabinets aren’t mobile, open windows and use a box fan to keep air moving. Next, be sure to wear a respirator when working with chemicals or sanding to avoid inhaling harmful substances. Finally, avoid damaged or stained skin by donning a pair of chemical resistant gloves.

Finally, remember that some chemicals used in kitchen cabinet refinishing (particularly during stripping or staining) are flammable, so be sure to play it safe around any heaters, open flames, or anything of the sort. Oily rags can also combust if left in a pile, so hang them to dry before throwing them out.

Advertisement

RELATED: The Best Under Cabinet Lighting of 2021

Method 1: Refinishing Cabinets to Make Them Lighter

Photo: istockphoto.com

Refinishing darker cabinets to make them lighter is probably the most involved method of refinishing, and it takes some specific knowledge, tools, and materials. With the following list and steps in mind, you should be able to remove the finish, paint, and stain from wood-based cabinets to bring them to a lighter finish.

With the following list and steps in mind, you should be able to remove the finish, paint, and stain from wood-based cabinets to bring them to a lighter finish.

– Sandpaper

– Paint stripper

– Chlorine bleach (if necessary)

– Wood filler

– Wood sealer

– Denatured alcohol

– Stain

– Varnish

– Respirator

– Rubber gloves

– Sanding block

– Scraper

– Putty knife

– Orbital sander

– Rags

– Paintbrush

– Steel wool

– Tack cloth

STEP 1 : Remove the cabinet doors.

Before embarking, remove one of the doors and sand off a small area of the finish on the back. Do the same to an area at the back of a rail or stile (horizontal or vertical framing member).

If the doors and drawer fronts are made of hardwood, remove them and take off all the hardware.

Note: If the doors and drawer fronts are fiberboard, forget about refinishing them with stain. The only way you’re going to get the cherry, oak, or birch tones you love so much is by applying a veneer or buying all new doors and drawer fronts.

STEP 2 : Strip the old finish from the cabinets.

In a well-ventilated room (or outdoors), use a paint stripper to remove the existing finish. Removing a clear coat finish should be a lot easier than removing paint, but you may have to use an aggressive stripper or chlorine bleach to remove the old stain. The job is messy and potentially unhealthy, but if you’re careful, it’s better than blowing thousands of dollars on new cabinets.

Note: Removing paint from cabinets, or any wood furniture, requires patience. Not all of the paint lifts off after the first application of remover, and maybe not after the second or third, either. It’s imperative to work in a ventilated space, to wear a respirator, to wear protective gloves and a long-sleeve work shirt.

Advertisement

Use a sharp scraper to remove as much finish as possible and use whatever you have on hand (old spoons, dental tools, etc.) to scrape contours and crevices.

STEP 3 : Fill damaged wood with wood filler, then proceed with sanding the cabinets.

Fill dents and deep scratches with wood filler, then sand thoroughly until all finish is removed and the wood is super smooth with no scratches.

Make your first pass with an orbital sander using 100-grit paper, your second with 180-grit paper, and your last pass with 220-grit.

STEP 4 : Apply a sealer.

Before applying it, thin out the sealer to a 50-50 concentration with denatured alcohol.

Apply the sealer (this is sometimes called a wood conditioner). A sealer does just what it says: It seals the surface with a light, thin coating so that when you apply stain, the color goes on evenly. Zinsser’s Bull’s Eye Seal Coat, an alcohol-based sealer that’s easy to apply and dries fast, is a good option.

When the sealer dries, lightly rub with 000 steel wool, then clean the surface thoroughly with a tack cloth.

STEP 5 : Apply the stain.

Apply stain using a soft cotton rag, a brush, or a brush in combination with a rag. Experiment until you find a combination that allows you to apply a consistent tone.

If the stain is going on too dark, rub some it off. Too light? Don’t worry. You can apply another coat after the first one dries.

Once the stain dries, follow up with another very light rubbing with 000 or 0000 steel wool before cleaning with tack cloth.

Note: It’s always wise to experiment on the backside of a single door before committing to the project, just to be sure you’re going to be pleased with the results.

Advertisement

STEP 6 : Add a protective varnish to the cabinets.

Now you can apply a protective coat of clear polyurethane varnish. Applying any clear coat must be done in a dust-free environment.

Read the directions on the can and follow them, but when it comes to thinning, you may need to deviate from the product literature. Most makers say you won’t have to, and maybe that is the case under perfect conditions, but I find that it’s usually necessary to pour in a little mineral spirits to keep the polyurethane flowing smoothly and drying without brush marks.

RELATED: These Cabinet Customizations Are Totally Worth It, According to Pro Organizers

Method 2: Refinishing Kitchen Cabinets to Make Them Darker

Photo: istockphoto.com

If you want darker-toned cabinets than what you currently have, you may be able to simply tint the existing finish. This method of refinishing kitchen cabinets, or cabinetry in any space, is much easier to accomplish than others that require stripping and sanding, but there are still a few ins and outs that you need to know.

SUPPLIES– Respirator

– Rubber gloves

– Trisodium Phosphate (TSP)

– Water

– Sandpaper

– Tack cloth

– Tinted polyurethane varnish

– Paintbrush

– Polyurethane finish

STEP 1 : Remove and wash doors and drawer fronts.

After removing the doors, drawers and hardware; begin by thoroughly washing grease and wax off the cabinets with TSP and water.

STEP 2 : Sand and dust the cabinets.

Lightly sand and wipe off the dust with a tack cloth.

STEP 3 : Apply a tinted polyurethane.

Experiment with a tinted polyurethane varnish (such as Polyshades by Minwax) to see if you can achieve the tone desired. Tinted polyurethanes combine stain and varnish in a single product.

Note: It’s always wise to experiment on the back side of a single door before committing to the project, just to be sure you’re going to be pleased with the results.

Advertisement

RELATED: How to Stain Cabinets

Method 3: Repainting Kitchen Cabinets

Photo: istockphoto.com

While it might make the biggest impact, repainting kitchen cabinets is actually quite a bit easier than restaining them. And, since you’re applying a whole new coat, the color possibilities are endless.

SUPPLIES– Respirator

– 220-Grit sandpaper

– Foam sanding block

– Tack cloth

– Degreaser

– Primer

– Paintbrush

– Paint roller and tray

– Enamel cabinet and trim paint

STEP 1: Remove the cabinet doors and hardware.

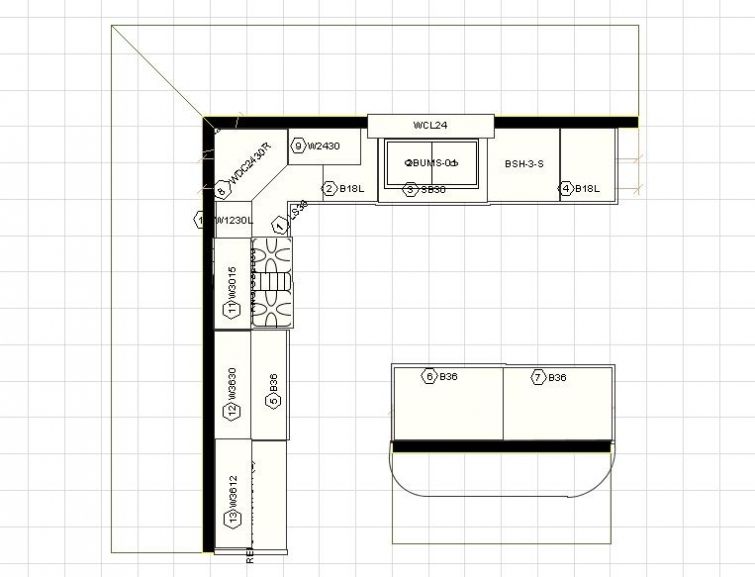

Start by removing the doors, door knobs, drawer fronts, drawer pulls, and other hardware from the cabinets. For very large kitchens, it’s a good idea to number the cabinet doors and drawer fronts to ensure you know where to put them back.

STEP 2: Lightly scuff the cabinets’ surfaces.

Cabinets are typically smooth and covered with a bit of polyurethane. While primer can adhere to this surface, it’s better to scuff it up a bit first. Put on a respirator and use the 220-grit sandpaper and foam sanding block to lightly scuff the surface of the boxes, face frames, drawer fronts, and doors. The foam sanding block should be able to get into intricate door profiles.

Keep in mind that your goal isn’t to sand down to bare wood. Instead, you simply want to roughen the surface of the existing finish to give the primer something to hold on to.

RELATED: The Best Primers for Kitchen Cabinet Transformations

STEP 3: Clean the cabinet surfaces.

After scuffing, remove the dust from the cabinets with a tack cloth. Take your time with this step as any dust that stays behind is going to create a rough texture on the cabinet.

While you’re sanding, you’re inadvertently transferring oils from your fingers to the cabinets. Also, cabinets see a lot of cooking oil, as well, and neither substance is conducive to a great paint job. The answer to this conundrum is to use the degreaser to clean the entire surface of the boxes and doors. Once clean, the surface is ready for primer.

Advertisement

RELATED: The Best Paint for Kitchen Cabinets

STEP 4: Prime the cabinets.

After pouring primer into the paint tray, use the paintbrush and roller to coat the boxes, face frames, doors, and drawer fronts with primer. Be sure to brush the primer into any cracks or corners, especially along the door profiles. This finish might look a bit streaky, but you should only need one coat of primer before moving to paint. Pour the excess primer back into the can and clean the brush and paint tray while allowing the primer to dry.

Pour the excess primer back into the can and clean the brush and paint tray while allowing the primer to dry.

STEP 5: Paint the cabinets.

Once the primer dries, it’s time to paint the cabinets. Put a new roller cover on your paint roller and pour some paint into the paint tray. Use the brush and roller to coat the doors, face frames, drawer fronts, and boxes with an enamel paint made specifically for cabinets and trim for the best results. After allowing the first coat to dry, apply a second coat of paint. Once dry, put all the doors, drawer fronts, and hardware back on and enjoy the fresh, new, updated look in your kitchen.

RELATED: The 14 Freshest Kitchen Cabinet Colors

Final ThoughtsPhoto: istockphoto.com

With this primer on how to refurbish kitchen cabinets, you have the knowledge necessary to give those boring or ugly wood boxes and doors a facelift. Whether sanding down to bare wood and restaining kitchen cabinets, using a tinted varnish to darken the color, or painting your cabinets, be sure to wear the proper safety gear while you tackle this big-impact project.

That might feel like a lot of information about the refinishing kitchen cabinets, and it’s hard to cover everything in one coat. If you still have questions about restaining cabinets or simply refurbishing old kitchen cabinets, this section is for you.

Advertisement

Q: What is the average cost to refinish cabinets?Generally speaking, the cost of refinishing kitchen cabinets (with labor) will run between about $1,800 and $4,000, depending on the size of the kitchen. You can save up to 75 percent of that cost if you tackle the project yourself.

Q: Is it worth it to refinish kitchen cabinets?It is absolutely worth refinishing kitchen cabinets. If your boxes and doors are still in good shape, a fresh coat of stain or paint can breathe new life into an old space and save you up to $20,000.

Q: Is it cheaper to reface or refinish cabinets?Generally speaking, refinishing cabinets is less expensive than refacing kitchen cabinets. Cabinet refacing costs, on average, $7,132.

Cabinet refacing costs, on average, $7,132.

Usually, discoloration is caused by old stain that’s deeply embedded in the wood. Liquid strippers and sanding might not even be an option, so it’s best to go with a darker stain or paint that will hide the blotchiness.

Refinishing your cabinets?

Get free, no-commitment project estimates from pros near you.

Find Pros Now

+Tips for Refinishing Kitchen Cabinets

While it may be tempting to rush through—or even skip—the preparation process, if you truly want your finish to look good and last a long time, prep is the most important step. And the techniques you employ, and the products you use, can make or break your outcome. Follow these steps and you’ll be on your way to a foolproof finish.

The “Before”

Courtesy Nick SlavikThe wood cabinets were in great shape, but the dark finish was outdated, and made the space feel small and dreary.

Protective Measures

Courtesy Nick SlavikStart by laying down floor protection, and then cover countertops so they can double as a work surface. You can use canvas drop cloths, but personally I prefer builder’s paper, as it protects well, it’s affordable, and it’s easily discarded/recycled.

Preparation Pays Off

Courtesy Nick SlavikYes, some people would say I go a little crazy with prep, but from experience I know that it’s not wasted time. Remove all of the doors and drawers, label/number them carefully (you’ll thank me later), and stage them for cleaning. Plastic and tape off all of the insides of the cabinet boxes to keep dust from getting in, cover all backsplashes with plastic, and seal all appliances to keep them clean.

Degrease

Courtesy Nick SlavikOn to the cleaning process. Scrape off any food residue from the cabinets and then wash/scrub with synthetic steel wool and soap and water. For tough grease, use TSP (trisodium phosphate) and water; the TSP actually emulsifies the grease and removes it much more efficiently than soap alone. Let dry completely before moving on.

For tough grease, use TSP (trisodium phosphate) and water; the TSP actually emulsifies the grease and removes it much more efficiently than soap alone. Let dry completely before moving on.

Prep, Part One: SVT

Courtesy Nick SlavikThis is the key step to prep: SVT (Sand, Vac, and Tack). Sand the cabinets with medium-grit sanding sponges and/or 180-grit sandpaper on a random orbital sander. It’s not essential to remove all of the finish, but you must scuff it to give it “tooth” and promote adhesion. Once 100% of the surfaces are sanded, use a shop vac with a brush attachment to remove the majority of the dust. The last step is to tack-rag off the residual dust. The best method is to use a microfiber rag with water–but remember to wring out almost all of the water, as residual water will leave spots.

Prime Time!

Courtesy Nick SlavikChoosing the correct primer is so important. The wrong primer will leave you with chipping cabinets, an uneven finish, and even stain bleeding from the wood. KILZ 3® Premium Primer, in my experience, is easy to apply, adheres wonderfully and blocks stains. A major benefit is that it has low odor, so families can continue to live in the house while work is done. (This is unlike most traditional oil primers which have a very noticeable odor.) And KILZ 3 Premium Primer dries to the touch in 30 minutes and can be top-coated in one hour; this will help with achieving a dust-free finish.

The wrong primer will leave you with chipping cabinets, an uneven finish, and even stain bleeding from the wood. KILZ 3® Premium Primer, in my experience, is easy to apply, adheres wonderfully and blocks stains. A major benefit is that it has low odor, so families can continue to live in the house while work is done. (This is unlike most traditional oil primers which have a very noticeable odor.) And KILZ 3 Premium Primer dries to the touch in 30 minutes and can be top-coated in one hour; this will help with achieving a dust-free finish.

Application

Courtesy Nick SlavikPriming is fairly straightforward: apply as uniformly as possible, and be super thorough. Application can be done with brush, roller, or sprayer. For this project I’ll be demonstrating brush and roller application. The best brush for painting cabinets will have super-fine nylon bristles. This will leave a finish nearly devoid of brush marks. Don’t skimp on this. Expect to pay between $15 and $25 for a good brush. Properly cleaned, it will give you decades of service. When choosing a roller for painting cabinets, I prefer a very high-quality woven cover. This will prevent shedding of fibers and a flawed finish. For the nap, I like ¼” or ⅜”. Anything thicker will leave excessive stipple.

Don’t skimp on this. Expect to pay between $15 and $25 for a good brush. Properly cleaned, it will give you decades of service. When choosing a roller for painting cabinets, I prefer a very high-quality woven cover. This will prevent shedding of fibers and a flawed finish. For the nap, I like ¼” or ⅜”. Anything thicker will leave excessive stipple.

Prep, Part Two: Repeat SVT

Courtesy Nick SlavikOnce the primer is dry I like to repeat the SVT process: lightly scuff-sand to promote adhesion and remove any minor flaws left on the cabinets, and vacuum and tack-rag again before caulking any cracks. I prefer to caulk cracks (where the cabinets meet walls, crown molding, etc.) after priming. Caulk will always stick better to a primed surface than to bare wood. However, never caulk the panels on cabinet doors—they’re actually called “floating panels” and need to move with seasonal temperature and humidity fluctuations. I’ve seen some really bad effects from caulking these panels, such as peeling caulk and even cracked door panels. It’s tempting to caulk these, but you’ll have to abstain—trust me on this one. Let any caulk dry completely before moving on.

It’s tempting to caulk these, but you’ll have to abstain—trust me on this one. Let any caulk dry completely before moving on.

Top It Off

Courtesy Nick SlavikNow that you have a perfectly primed surface, it’s time for the top coat. The application techniques are the same as priming—use a high-quality nylon-bristle brush and/or roller, and take your time to ensure smooth, even coverage. Start by coating the back sides of the doors and lay them flat. Laying doors flat will help with the leveling of the enamel and give you a smooth finish. Once dry, you can flip the doors over and coat the fronts. For the cabinet boxes, try to keep a wet edge (don’t start and stop, allowing the paint to dry). I recommend applying a second top coat for added protection and an even shine.

De-Prep (Almost There!)

Courtesy Nick SlavikOnce everything has dried to the point where you can handle it, start by removing the tape and plastic from the cabinets. Install the doors one by one. (Now, you get to see if your door labeling system was effective!) Save any adjustments of the doors until the end. I use only hand tools when installing doors and drawers; drills tend to strip out delicate screws. Install any knobs or pulls, and make any necessary adjustments to get them all straight. Pro’s Note: Clients love when you install new clear rubber bumpers on the doors and drawers (they were removed during the prep process). It’s a small detail, but well worth the effort.

Install the doors one by one. (Now, you get to see if your door labeling system was effective!) Save any adjustments of the doors until the end. I use only hand tools when installing doors and drawers; drills tend to strip out delicate screws. Install any knobs or pulls, and make any necessary adjustments to get them all straight. Pro’s Note: Clients love when you install new clear rubber bumpers on the doors and drawers (they were removed during the prep process). It’s a small detail, but well worth the effort.

Photo Finish

Courtesy Nick SlavikTake one final walk-through to look for touch-ups; if you’re satisfied, then you can go ahead and remove the plastic, paper, and tape from countertops, appliances, and floor, and consider your job well done!

KILZ 3

® Premium Primer is designed for use on interior and exterior surfaces including woodwork, drywall, plaster, paneling, masonry, brick, painted metal, and properly prepared glossy surfaces. To learn more, visit KILZ.com

To learn more, visit KILZ.com Do-it-yourself repair of a partially broken wardrobe

- Common problems

- Hull repair

- Failure of fittings for internal filling

- How to update wardrobe doors

- We update the appearance of the wardrobe

Do-it-yourself wardrobe restoration will make it possible to save on the purchase of this useful interior detail. An old or broken wardrobe can be easily repaired and updated. The most common cause of breakdowns is considered to be door malfunctions, and restorations are the loss of the surface of its appearance. Now we will analyze several options for how to update an old wardrobe with your own hands and fix existing problems. nine0017

Common problems

Before you repair your closet and update its appearance, you should understand the type of damage. Among the most common, we highlight the following:

- damage to the cabinet body or internal partitions;

- failure of fittings for internal filling;

- failure of the system of rollers and door closers;

- loss of aesthetic and commercial appearance of both the entire product and its individual elements; nine0004

In all these cases, it is quite possible to repair the sliding wardrobe yourself, for which you will need accessories and tools.

Hull repair

First of all, remove the cabinet doors, then, if necessary, remove the lower and upper rails. Further, either complete or partial disassembly of the case may be necessary - for fixing which they often use either an eccentric coupler or the so-called euro screws that must be unscrewed. If necessary, you need to order additional sets of fasteners. nine0017

If the case has mechanical damage, the panel will have to be replaced. By the way, it is recommended to buy in advance accessories for wardrobes in those sets that will be needed.

Fittings for wardrobe

Wardrobe accessories

Chipboard panels are most often used to repair the hull. You can replace the entire panel, or you can replace only a part, if the design allows it. In any case, you should carefully adjust the dimensions to the existing furniture format. nine0017

Knowing how to fix a closet, you will not face serious problems. You should pay attention to the correct installation of the doors - first, the body is installed using a level, then we install the doors and achieve the correct location by adjusting the screws on the rollers.

You should pay attention to the correct installation of the doors - first, the body is installed using a level, then we install the doors and achieve the correct location by adjusting the screws on the rollers.

Failure of fittings for internal filling

Mechanics may not work due to contamination - remove the doors according to the above algorithm and clean the guides. Don't forget to use a level when installing doors. It is possible that the guides are installed incorrectly, in which case they will have to be dismantled and reinstalled, experimentally selecting the position at which the doors move freely. nine0017

How to update wardrobe doors

In principle, mechanical problems (loose closure, play, difficulty in moving) are a reason to completely renew the part. You can even completely replace them by choosing the appropriate sliding doors for the wardrobe. You should be guided by the dimensions of the models, since the doors fit only the format of the cabinet itself. If the furniture is made to order, you will have to order parts with a measurer's call.

If the furniture is made to order, you will have to order parts with a measurer's call.

Before repairing the wardrobe doors, the other furniture problems described above should be corrected. Next, remove the doors and put new ones. We begin the installation by attaching the guides, first of all, the upper track is attached. It is necessary to fasten the track with self-tapping screws, making holes in the body every 50-60 mm. nine0017

Installing the top profile

Next, we are engaged in the lower track, but we do not fix it, but only outline the places for self-tapping screws. Do-it-yourself wardrobe door repair implies a precisely adjusted level - we fix it after installation.

We fasten the rollers to the door leaf and insert the door into the rails, check how the door moves along the tracks. There should not be too much play or difficulty in moving. Using the mounting level, we achieve a perfectly vertical position of the part. As soon as this happens, we fix the bottom track in its existing position, taking into account the vertical. nine0017

As soon as this happens, we fix the bottom track in its existing position, taking into account the vertical. nine0017

Sliding systems for sliding wardrobes are quite heavy, so before the final fixing, you should check the vertical level of the entire cabinet.

We update the appearance of the wardrobe

Of the other options for repairing wardrobe doors with your own hands, you can note the general painting of furniture. It is advisable to use acrylic paints for these purposes. This allows you to significantly update the entire appearance of the cabinet - for painting it is simply disassembled according to the above algorithms. Before painting, be sure to sand the surface and apply a primer to it. You can use various design options for coloring - it already depends on your personal preferences. Or order a finished case in a new design. At the door, if you are not satisfied with the filling, you can replace it, having previously calculated all the sizes of the inserts. nine0017

nine0017

Now you know how to update a sliding wardrobe without calling a wizard. This is not the most difficult job, if you follow the accuracy and all the rules. Such furniture requires regular maintenance - this will make it possible to save on the purchase of new options

Create a wardrobe!

How to fix a cabinet door: methods and recommendations

Advertisement

Contents:

- Major door defects

- Cabinet door hinge repair

- Fixing magnet

- Mechanical damage to the door or handle

- Chipboard cabinet door repair

- Recommendations

Furniture is an obligatory attribute of any living space, creating coziness and comfort. At the moment, most interior items are made from chipboard (chipboard). Thanks to this, the furniture has a low cost and an attractive appearance. However, this also has disadvantages, namely, fragility. During operation, metal fasteners can violate the integrity of the material or completely destroy it. This affects all furniture that has a door, including a closet. How to fix the door with your own hands? Let's figure it out. nine0017

This affects all furniture that has a door, including a closet. How to fix the door with your own hands? Let's figure it out. nine0017

Major door defects

Wardrobe, like any piece of furniture, needs constant care. Otherwise, sooner or later, problems arise that require cardinal solutions. The metal parts of the interior also need care, as they can rust, start to creak when the door is opened. Problems specific to furniture materials:

- Scratched door surface.

- The handle does not work or is broken. nine0003 The door makes unpleasant sounds when it is moved.

- The door does not close or does not fit tightly.

Cabinet door hinge repair

Some problems with hinges can be solved by yourself, in more difficult situations it is easier to replace them with new ones. When opening or closing the door, an unpleasant creak may appear, which is emitted by the door hinges. To fix the problem, you need to prepare a syringe and special oil for hinges (can be replaced with engine oil). nine0017

nine0017

If the necessary equipment is at hand, then it will take only a couple of minutes to solve the problem, which can save the residents of the house from an unpleasant and annoying squeak. To do this, just draw oil into a syringe and carefully lubricate the loop, using just a couple of drops for this.

Correcting the magnet

Another problem that can be encountered is that the cabinet door is constantly opening and cannot be closed. Before, people took a piece of newspaper, rolled it up and put it under the door. Now you can solve the problem yourself by first defining the type of construction:0017

- With magnet.

- Without magnet.

If the cabinet door is on a small magnet and is held closed by a metal bar, then it is enough to adjust the magnetic fastening using a screwdriver. Procedure:

- Loosen the screws holding the magnet (do not remove).

- Move it slightly forward.

- Retighten the screws.

- Completely replace the fixture if the desired result is not achieved. nine0004

If the door does not have a magnet, then you will have to make a gasket, taking a small piece of rubber for this. Also useful:

- Knife.

- Ruler.

- Handle.

- Hammer and nails.

- Glue.

To fix the problem, cut out a rubber gasket (2*3 cm) 1-5 mm thick and glue it to the bottom rail of the box. You can provide a more secure fastening by replacing the glue with a hammer and small nails. nine0017

Mechanical damage to the door or handle

If there are deep scratches on the cabinet door that spoil the beauty of the furniture, then there are only two ways: restoration or complete replacement. As for the door handle, it is easier to replace it by buying a similar or exactly the same one. To install a new handle, a screwdriver is needed, with which the following procedure is performed:

- Open the doors.

- Remove the screws.

- Remove handle.

- Attach a new handle. nine0004

- Screw in screws, but do not tighten.

- Adjust the handle to the correct position.

- Tighten screws.

Chipboard Cabinet Door Repair

The most common problem homeowners face is screws or screws flying out of the woodwork. As a result of this, a hole appears in that place, and it is impossible to insert a new mount there. You can solve the problem in one of the following ways:

- Install a different type of hinge. nine0004

- Seal the hole with a mortar of glue and sawdust or a special compound.

- Fit wooden bushings.

- Install a metal or wood plate.

Glue and sawdust

If the furniture is made of soft chipboard, it can be repaired using sawdust and PVA glue. The advantage of this method is that the door does not need to be removed from the cabinet to repair the door, it is enough to carry out the following procedure:

- Make a thick homogeneous mass by mixing glue and sawdust.

- Treat the damaged area by repairing the hole.

- Allow the compound to dry.

- Soak the self-tapping screws in the same mixture and screw in.

Epoxy resin

Epoxy resin will give a more reliable and durable result, which can be applied in this way:

- Mix resin with large sawdust.

- Close the hole.

- Allow material to dry, waiting 1 day. nine0004

- Drill new holes for self-tapping screws.

- Install the bracket and secure the door.

New hinge

If you do not want to deal with repair procedures, you can buy new door hinges of a different type, type and size, installing them in a different place. To do this, an unnecessary hole must be covered with furniture wax, and a new mount must be attached a few centimeters lower or higher than the previous one.

Wooden plug

To repair a heavy closet door, you will need the following inventory:

- Hammer.

- Glue.

- Knife.

- Rag.

- Hardwood (birch or oak).

Now proceed as follows:

- Cut out two cone-shaped wooden plugs.

- Lubricate the hole and plug with adhesive.

- Hammer the plug into the hole.

- Remove excess adhesive with a cloth.

- Let dry.

- Place the hinge on the prepared place.

Special tool

You can also use a restoration tool that resembles plasticine in consistency to repair the door. By purchasing a special substance from Heinkel, you can quickly solve the problem by doing this:

- Mash the composition.

- Moisten the area to be restored.

- Close up the hole.

- Let dry.

- Install hinge.

Metal or wood plate

Holes that have appeared in the place of fallen screws can not be repaired, but closed using a wooden or metal plate for this. Operating sequence:

- Remove the door and unscrew the hinges.

Learn more