Prices for installing hardwood floors

How Much Does Hardwood Flooring Cost?

Hardwood flooring is both durable and sophisticated. Read on to learn how much it costs to install.

Reviews by This Old House Reviews Team 03/23/2023 1:00 pm

Hardwood is a popular flooring material that can increase the value of your home. While it’s extremely durable and sophisticated, it comes with high up-front installation costs. Below, we outline the cost to install several different types of hardwood floors, plus list the pros and cons of this type of flooring.

Average Hardwood Flooring Cost

The average cost of installing hardwood floors is $3–$10 per square foot for materials and $3–$8 per square foot for labor, totaling $6–$18 per square foot. A single 200-square-foot room might cost $1,200–$3,600, while a 2,000-square-foot house could cost $12,000–$36,000. Wood quality influences price, with high-end flooring costing up to $25 per square foot. Square footage is the greatest determinant of price. Still, the following factors also come into play:

- Type of flooring: Solid hardwood is traditional, but you can also opt for engineered hardwood or parquet.

- Tree species: The more durable and less common the wood type, the more it costs.

- Thickness: Thicker boards can withstand more refinishing and therefore cost more.

- Grade: High-quality boards cost more than low-grade ones.

- Cut/grain: The way the boards are cut from the tree can mean more or less labor and waste.

Hardwood Flooring Cost by Type of Hardwood

Hardwood flooring cost varies based on the price of the material and the labor involved in installation. Traditional solid hardwood flooring consists of real wood planks cut from trees, which are installed end-to-end. Engineered wood flooring, which has a real wood veneer attached to a plywood base, may be slightly less expensive. Parquet flooring uses smaller pieces of real wood to create geometric designs, such as a herringbone pattern, making it the most expensive to install. Prefabricated, parquet-like tiles are a lower-cost alternative that give the appearance of parquet but are easier to install.

Engineered wood flooring, which has a real wood veneer attached to a plywood base, may be slightly less expensive. Parquet flooring uses smaller pieces of real wood to create geometric designs, such as a herringbone pattern, making it the most expensive to install. Prefabricated, parquet-like tiles are a lower-cost alternative that give the appearance of parquet but are easier to install.

| Type | Material Costs | Installation Costs | Total Cost per Sq. Ft. |

|---|---|---|---|

| Solid hardwood | $2–$20 | $3–$8 | $5–$28 |

| Engineered wood | $3–$14 | $3–$9 | $6–$23 |

| True parquet | $3–$18 | $10–$22 | $13–$40 |

| Parquet-style tiles | $3–$5 | $7–$10 | $10–$16 |

Hardwood Flooring Cost by Tree Species

Tree species greatly influences the cost of traditional hardwood. There are several types of wood to choose from that vary in appearance and performance. Some tree species are more durable than others or better suited to certain types of climates. Generally, the harder and more durable the wood is, the more expensive it is.

Some tree species are more durable than others or better suited to certain types of climates. Generally, the harder and more durable the wood is, the more expensive it is.

| Species | Cost per Sq. Ft. |

|---|---|

| Bamboo | $2–$6 |

| Brazilian walnut | $5–$10 |

| Cherry | $4–$7 |

| Cypress | $4–$6 |

| Hickory | $3–$7 |

| Mahogany | $6–$8 |

| Maple | $3–$10 |

| Pine | $2–$4 |

| Red oak | $2–$6 |

| Teak | $9–$13 |

| White ash | $5–$8 |

| White oak | $4–$7 |

Hardwood Flooring Cost by Thickness

Traditionally, hardwood floorboards are three-quarters of an inch thick. Thinner boards—down to five-sixteenths of an inch thick—are less expensive, but you won’t be able to sand and refinish them as many times.

| Thickness | Cost per Sq. Ft. Ft. |

|---|---|

| 5/16” | $2–$5 |

| 3/4” | $3–$10 |

| 7/8” | $5–$15 |

Hardwood Flooring Cost by Grade

Solid hardwood flooring comes from living trees, so it’s not as standardized in quality as factory-made flooring material. Different vendors have different standards for grading their products’ quality; for example, some grades refer to grain pattern, texture, or appearance rather than durability. In general, hardwood boards of the same species and cut have three tiers of quality that determine their cost:

| Grade | Cost per Sq. Ft. |

|---|---|

| Low-tier | $2–$6 |

| Mid-tier | $5–$10 |

| High-tier | $8–$18 |

Hardwood Flooring Cost by Cut and Grain

The way wood is cut creates its grain pattern, which can play into price relative to the species of tree. Plain-sawn or flat-sawn planks are cut parallel to the tree’s growth rings to create a wave or flame-like grain pattern. Quarter-sawn planks, on the other hand, are cut at a 60–90 degree angle from growth rings for a straighter grain pattern. Flat-sawn boards are more common and therefore less expensive, while quarter-sawn boards are pricier but wear more evenly. The rarest and most expensive are rift-sawn boards, which have the most linear grain pattern but create the most waste.

Quarter-sawn planks, on the other hand, are cut at a 60–90 degree angle from growth rings for a straighter grain pattern. Flat-sawn boards are more common and therefore less expensive, while quarter-sawn boards are pricier but wear more evenly. The rarest and most expensive are rift-sawn boards, which have the most linear grain pattern but create the most waste.

To estimate how much your flooring will cost, use the equation below, as illustrated in our Complete Guide to Hardwood Flooring article.

Free Quote: Get your hardwood flooring quote today

Hardwood Flooring Cost Factors

Beyond the type of wood, here are some factors that contribute to the total cost of hardwood flooring installation:

- Alternative flooring options

- Floor joist repairs

- Finish and coating

- Installation and labor

- Repair, replacement, and refinishing

Alternative Flooring Options

If you love the look of solid wood flooring but traditional or engineered hardwood is beyond your budget, there are alternative flooring options that mimic the appearance of wood. Vinyl or laminate flooring and porcelain tiles can be manufactured to look like wood for a fraction of the cost. Alternative real wood options, such as floating floors and click-and-lock paneling, can help you save money on installation.

Vinyl or laminate flooring and porcelain tiles can be manufactured to look like wood for a fraction of the cost. Alternative real wood options, such as floating floors and click-and-lock paneling, can help you save money on installation.

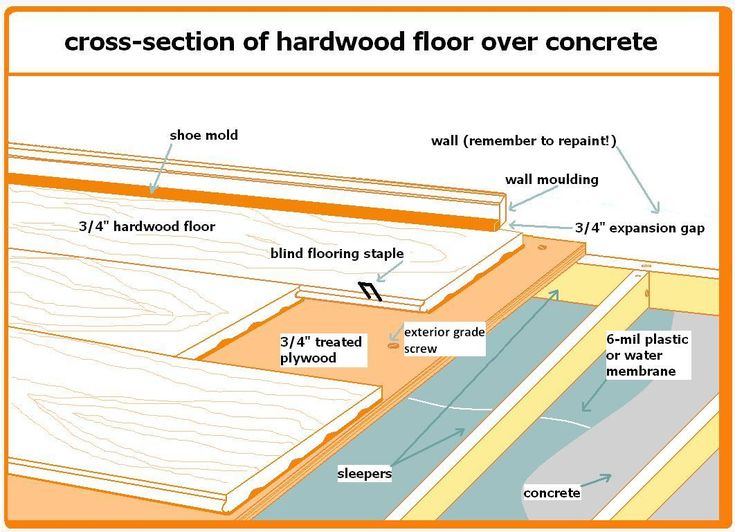

Floor Joist Repairs

When you replace your existing flooring, you may discover that the subfloor or joists have mold, insect, or water damage. In this case, you’ll need to have the joists repaired for an average cost of $2,000–$5,000 before any work can be completed.

Finishing and Coating

When installing new hardwood floors, you have two choices: boards that have been prefinished at the factory or unfinished boards that are finished with sealant following installation. Unfinished boards are less expensive but come with higher labor costs, since the finishing must be done on-site. Additionally, different types of finish have different costs, with polyurethane on the low end and penetrating resin finish on the high end.

Installation and Labor

Hard and exotic woods have higher material and installation costs, while softwoods like pine are easier to work with and cheaper to install. Parquet and small wood tiles with intricate patterns are pricier to install, as is flooring in rooms with unusual layouts or staircases.

Parquet and small wood tiles with intricate patterns are pricier to install, as is flooring in rooms with unusual layouts or staircases.

Repair, Replacement, or Refinishing

Hardwood flooring may be expensive to install, but you can easily refinish it. A professional sanding and floor refinishing project costs $3–$8 per square foot and will get rid of dents, dings, and even gouges. You may even refinish your floors yourself. Replacing individual boards will cost more, but it will still be just a fraction of the overall cost of having new floors installed.

Free Quote: Get your hardwood flooring quote today

Types of Hardwood Flooring

One of the most important decisions you’ll make when installing new hardwood floors is choosing the wood type. Here are some of the most common types of wood flooring and their characteristics:

- Maple: Light coloring, medium density, good for high-traffic areas

- Pine: Low cost, very soft, prone to dents, difficult to refinish

- Bamboo: Durable, shows few scratches, termite-resistant

- White ash: Light color, bold grain, medium density

- Hickory: High density and hardness, variable in color

- Red oak: Consistent color and finish, high durability, medium price

- White oak: More water-resistant than red oak, lighter color

- Brazilian walnut: Rich color, high durability

- Cypress: Moderate durability, termite-resistant

- Cherry: Rich color, soft, best for bedrooms and low-traffic areas

- Teak: High price, very hard, scratch-resistant

- Mahogany: Dark color, ages well, medium price

Pros and Cons of Hardwood Flooring

Below, we outline the benefits and drawbacks of installing this type of flooring.

Pros of Hardwood Flooring

Durability and value are among the top benefits of hardwood flooring. Some other pros include the following:

- Long-lasting with a 50- to 100-year lifespan

- Good for increasing resale value

- Easy to repair and refinish

- Relatively low-maintenance

- Versatile in appearance

- Less allergenic than carpeting

Cons of Hardwood Flooring

There are several cons to consider before installing hardwood flooring:

- Expensive to install

- Prone to scratches and gouges

- Susceptible to humidity and moisture damage

- Noisy when walked on, as they tap and creak

- Difficult for people and pets with mobility problems

DIY vs. Professional Hardwood Flooring Cost

Installation and labor are two of the most expensive aspects of installing hardwood flooring. To cut down on costs, homeowners may be tempted to take on the project themselves. There are some types of wood flooring, like click-and-lock wood tiles and floating flooring, that experienced DIYers may be able to install themselves. When it comes to traditional hardwood plank flooring, however, the job is best left to the professionals.

To cut down on costs, homeowners may be tempted to take on the project themselves. There are some types of wood flooring, like click-and-lock wood tiles and floating flooring, that experienced DIYers may be able to install themselves. When it comes to traditional hardwood plank flooring, however, the job is best left to the professionals.

Flooring contractors don’t necessarily have to be licensed, but it takes ample training and experience to properly account for variables such as changing temperatures, humidity, and moisture protection. Improperly installed wood floors are prone to cracking, bowing, and warping over time, so if you’re investing in hardwood flooring, we strongly recommend you have it professionally installed.

Free Quote: Get your hardwood flooring quote from pros near you today

How To Save on Hardwood Flooring Costs

Here are a few ways to save money on the overall project cost without having to do the work yourself.

Prioritize Savings Over Appearance

Think about wood flooring materials beyond just the color and finish. Look for a less expensive grain (plain-sawn), type of hardwood (pine, red oak, bamboo), and thickness (5/16”). You’ll also pay less for boards with more “character,” i.e., knots, varied colors, etc.

Look for a less expensive grain (plain-sawn), type of hardwood (pine, red oak, bamboo), and thickness (5/16”). You’ll also pay less for boards with more “character,” i.e., knots, varied colors, etc.

Consider Engineered Wood

It can cost more to install, but you can often save money by opting for engineered wood with non-exotic veneers. Depending on the type of panels, you may even be able to install it by yourself.

Whenever Possible, Refinish

If you already have hardwood floors, refinishing the old flooring will cost much less than installing new wood. Unless there are deep gouges or the floors have significant moisture damage, refinishing is usually the way to go.

How To Install Hardwood Floors

Installing hardwood flooring is a complicated process, but here are the basic steps. You can learn more in our comprehensive guide to hardwood floor installation.

- Let the flooring material acclimate to the home’s temperature and humidity.

Check for warps or other damage to the material.

Check for warps or other damage to the material. - Remove the old flooring and clean and prepare the subfloor.

- Lay and install the boards while staggering the gaps, leaving room for expansion and using boards from different boxes.

- Cut any excess underlayment, then sand and stain the boards.

- Add thresholds.

How To Hire a Professional

When choosing a flooring contractor, here are some things to keep in mind:

- Make sure the company is fully licensed, bonded, and insured.

- Find out which contractor or sub-contractor will perform the work.

- Ask for references from past clients and view samples of the company’s previous work.

- Read customer reviews on sites such as Yelp, TrustPilot, and Google Reviews.

- Check the company’s Better Business Bureau (BBB) rating and accreditation status.

- Get every estimate and warranty in writing.

- Examine at least three companies before making your choice.

Free Quote: Get your hardwood flooring quote from pros near you today

Our Conclusion

Hardwood flooring costs are substantial, and no flooring material is perfect. Still, hardwood floors have a lot of benefits, including a high return on investment. You also have more options than just installing wide planks in the traditional manner. Take some time to explore your wood flooring options and how they fit into your budget to determine whether hardwood floors are the right choice for your home.

Frequently Asked Questions About Hardwood Flooring

To share feedback or ask a question about this article, send a note to our Reviews Team at [email protected].

How Much Does Hardwood Flooring Cost? [2023 Data]

How Much Does Hardwood Flooring Cost? [2023 Data] | AngiNormal range: $2,484 - $7,027

The average cost to install hardwood flooring is between $2,484 and $7,027, depending on the size of your room and quality of materials.

Photo: Woning Media / iStock / Getty Images Plus / Getty Images

Photo: Woning Media / iStock / Getty Images Plus / Getty Images

Adding hardwood floors to your space is an investment that can lead to major benefits. For one, it’s easier to care for and maintain than carpet—so parents can say goodbye to juice stains forever. It’s also more long-lasting than tile because it can be finished (and refinished!) time and time again. In most cases, it can serve your home for a lifetime.

See the price range for hardwood flooring in

your area

Normal range for U.S.

$2,484 - $7,027

- Average

$4,720

- Low end

$1,000

- high end

$12,000

LOWHIGH

What Factors Influence the Cost of Installing Hardwood Flooring?

The cost to install hardwood flooring comes down to a handful of factors, including the type of wood you choose and the specific needs of your home.

Photo: Alesia Kazantceva / Unsplash

Room Size

The national average cost to install hardwood flooring is $6 to $12 per square foot for both labor and material fees. For higher-end wood and larger spaces, like if you’re redoing your entire first floor in hardwood, you may pay more—possibly between $13 and $25 per square foot. In general, most projects end up costing between $2,490 to $6,760 total.

Here’s what you may pay depending on your home size and how much flooring you’re interested in replacing:

| Amount of Flooring | Typical Cost Range |

|---|---|

| 500 sq. ft. | $3,000 – $6,000 |

| 1,000 sq. ft. | $6,000 – $12,000 |

| 1,200 sq. ft. | $7,200 – $14,400 |

| 2,000 sq. ft. | $12,000 – $24,000 |

Type of Hardwood Flooring

Your hardwood flooring material and installation costs will depend in part on the type of flooring you choose.

| Type of Floor | Total Material and Installation Cost |

|---|---|

| Solid Hardwood | $5 – $28 per sq. ft. |

| Prefinished Hardwood | $6 – $12 per sq. ft. |

| Engineered Hardwood | $4.50 – $16 per sq. ft. |

| Genuine Parquet | $20 – $45 per sq. ft. |

| Faux Parquet | $7 – $15 per sq. ft. |

Type of Wood

Hardwood floors consist of many different tree species. Each type has a unique look and varies in hardness, performance, and price. Woods that are harder, more durable, or exotic tend to cost more. This includes red oak, Brazilian cherry, and hickory.

Wood Hardness

The harder a wood is, the more of an effort it takes to install. Expect hardwoods (think Brazilian walnut) to require more elbow grease than softwoods (pine).

Thickness

Hardwood is typically 3/4 inches, 5/16 inches, and 1/2 inches thick, though you can also find options in other thicknesses. Thicker flooring can cost a bit more than thinner floors. For instance, hardwood floors that are 5/16 inches thick can cost $2 to $5 per square foot, while planks that are 3/4 inches thick can cost up to $6.

Thicker flooring can cost a bit more than thinner floors. For instance, hardwood floors that are 5/16 inches thick can cost $2 to $5 per square foot, while planks that are 3/4 inches thick can cost up to $6.

Wood Grade

You’ll find that hardwood flooring products fall into categories or grades based on physical characteristics. Low-grade floors have a natural, rustic character with knots, color variations, and mineral streaks. These cost $6 to $18 per square foot installed. High-grade wood, or clear wood, has a more uniform look and color without imperfections. This tier costs $8 to $23 per square foot.

Width

Hardwood planks tend to be 5 inches wide or narrower. However, there are also wide plank formats that cost more, usually $4.50 to $18 per square foot for materials alone. You'll need fewer boards to cover a floor with wide planks (6- to 12-inch-wide boards), so they can reduce labor costs.

Color and Grain

Wood color varies dramatically across species. There are light and pale tones; warmer, medium tones; and rich, dark tones. Some darker exotic species tend to be more expensive.

There are light and pale tones; warmer, medium tones; and rich, dark tones. Some darker exotic species tend to be more expensive.

You'll also see price variations by cut. Plain-sawn planks with a wave-like pattern are the most affordable, while quarter-sawn planks have a straighter grain and are more expensive. One rare pattern is the highly linear grain of rift-sawn boards, which cost even more.

Labor

Most of the cost of wood flooring comes from materials, not labor. On average, labor only costs $3 to $6 per square foot. However, you may end up paying more for jobs that take longer. This includes installing planks that have to be finished on-site, patterns like herringbone and parquet, or installations in complex layouts with unique corners.

On the other hand, you may only spend $3 to $4 per square foot on labor when installing wide plank floors since they cover more area and take less time to put in.

Hardwood Flooring Cost by Type of Flooring

Hardwood flooring is actually a broad category that includes several different styles and patterns of flooring. Solid hardwood is the traditional type, but you'll also find engineered wood and parquet flooring made from wood. Material and installation costs will vary depending on which one you choose.

Solid hardwood is the traditional type, but you'll also find engineered wood and parquet flooring made from wood. Material and installation costs will vary depending on which one you choose.

Cost for Prefinished vs. Traditional Hardwood Flooring

Prefinished hardwood flooring is wood planks that have been finished before being installed, unlike traditional hardwood flooring, which is finished after installation. Opting for prefinished can cost between $6 and $12 per square foot. That might seem more expensive upfront, but it could actually save you money in the long run because finishing hardwood flooring on-site takes more time, which means more labor costs.

Adding the finishing after installation is also riskier because it’s a process that’s more likely to trap dust or debris on the surface of the wood. If the wood is finished beforehand, you don’t have to stress.

Cost for Engineered vs. Solid Hardwood Flooring

Engineered wood flooring is a more economical option than solid hardwood because it’s built from layers of hardwood and plywood rather than a single type. On the low end, it will cost between $4.50 and $9 per square foot. On the high end, you’ll pay between $9 and $16 per square foot.

On the low end, it will cost between $4.50 and $9 per square foot. On the high end, you’ll pay between $9 and $16 per square foot.

Think twice before deciding on this style because it’s not as durable as solid hardwood, which can last a century if the hardwood flooring is properly cared for.

Genuine Parquet

This is another style that costs more because it takes a lot of time and care to install. True parquet hardwood flooring can cost between $20 and $45 per square foot, but parquet-style tiles deliver a similar sophisticated look at a fraction of that price—you’ll pay $7 to $15 per square foot and $15,000 on average to install faux parquet.

Hardwood Flooring Cost by Type of Wood Species

There are many different types of wood to choose from, all with different costs.

Maple

Maple wood flooring is available in creamy white and warm red colors and will cost between $6.50 and $11 per square foot.

Pine

Pinewood flooring is among the more affordable options at $4. 50 to $10 per square foot. It can have a light beige or golden color, but it also dents more easily than other varieties.

50 to $10 per square foot. It can have a light beige or golden color, but it also dents more easily than other varieties.

“Pine is a wonderful choice because it looks great, it’s lightweight, and it’s easy to install,” says Bob Tschudi, Angi Expert Review Board member and general contractor in Raleigh, NC. “The downside is that it dents easily, but you can also sand those dents out rather quickly.”

Bamboo

You’ll pay between $5 and $11 per square foot for bamboo wood flooring. It’s pale yellow (and sometimes green), hard and durable, and, because bamboo regrows much faster than other trees, more sustainable.

White Ash

White ash wood flooring is available in either pale grey or light tan colors at $9 to $13 per square foot. It’s also extremely durable, hard to stain, and softer to the touch than most woods.

Hickory

Hickory can be found in many different colors and will cost between $6 to $13 per square foot.

Red Oak

As its name indicates, this type of wood is slightly red, and it has a tight, highly visible grain that’s great for adding texture to a space. You’ll pay $8 to $13 per square foot.

You’ll pay $8 to $13 per square foot.

White Oak

White oak wood flooring is light in color but just as strong and textured as red oak. It will cost between $8 and $15 per square foot.

Brazilian Walnut

This option is dark and cozy, but definitely on the pricier side at $11 to $20 per square foot.

Additional Costs to Consider

There are several other factors to consider when budgeting for new hardwood flooring. Consider whether your project will involve finishing your floors, repairing or replacing any existing flooring, or the removal of old surfaces like carpet.

Repair vs. Replace vs. Refinishing

If your current hardwood floors are in good shape with a few minor dents, dings, or gouges, you could refinish them. Refinishing hardwood floors costs about $3 to $8 per square foot. You can refinish solid hardwood multiple times, but engineered wood can only be refinished once or twice. Repairing or replacing individual boards costs more, but it’s still less costly than a new installation.

Carpet Removal

If you’re swapping carpet for wood floors, you’ll need to pay to have it removed. On average, the extra cost for carpet removal will be between $150 and $250. You can reduce your overall project cost by doing this step yourself.

Floor Joist Repairs

When replacing an existing floor, you or your installer may discover mold, insect, or water damage to the joists below. Extensively rotted joists will need repairs before you install new floors. Signs of damage are creaky floors and doors that begin to stick. Subfloor repairs can cost an additional $500 to $800, while joist repairs will be an extra $40 to $60 per square foot.

Finishing and Coating

Finish refers to the protective coating applied to hardwood to extend its durability. Some hardwood comes prefinished for an extra $2 per square foot, reducing labor costs. Finishing unfinished wood after installation adds $2 to $7 per square foot in labor.

Additionally, there are different types of finish that vary in cost. For example, polyurethane finish costs less than a penetrating resin finish.

Wood Look Tile

While not technically wood, wood-look tile is an affordable option for anyone who’s not ready to commit to hardwood flooring. This type of tile is glazed and colored to resemble wood, and there’s no risk of it rotting or warping in humid areas, so it’s perfect for your bathroom remodel! You can expect it to cost between $15 and $20 per square foot and from $900 to $2,900 for a full project.

Herringbone Pattern

If you opt for a gorgeous herringbone pattern, none of the materials you need will change—but the amount of time the project takes and the overall cost will. Choosing this style can add an extra 30% to your final bill because of the extra care required for installation. Expect to pay $12 per square foot of any type of wood to have it arranged in this fashion.

How to Calculate Hardwood Flooring Costs

To make sure the cost of your project doesn't take you by surprise, you can make some simple calculations in advance to get low- and high-cost estimates. Start by measuring the square footage of your space, then add 5% to 10% to account for cuts you'll make and waste material.

Start by measuring the square footage of your space, then add 5% to 10% to account for cuts you'll make and waste material.

Next, multiply your result by the hardwood material price per square foot. If you haven't chosen a hardwood product yet, use the average typical range of $6 to $12 to get the low and high end. Finally, add in the price of extra supplies like nails, moldings, and thresholds.

Cost to Install Hardwood Flooring Yourself

Most of the hardwood floor installation cost comes from materials rather than labor. Wood panels can cost $6 to $25 per square foot, whereas installation costs are $3 to $6 per square foot. Doing it yourself also requires certain tools that you might not already have, including a pneumatic flooring nailer, which can cost anywhere from $200 to $400.

DIY Hardwood Flooring Installation Cost vs. Hiring a Pro

Because your DIY savings will be minimal, it’s best to hire a local wood floor installer to do the job right. Proper installation of traditional solid hardwood flooring requires training, equipment, and experience that most DIYers don't have. Here are just a few things a pro will have experience with:

Proper installation of traditional solid hardwood flooring requires training, equipment, and experience that most DIYers don't have. Here are just a few things a pro will have experience with:

Accounting for changing temperatures and humidity

Installing vapor barriers for moisture protection

Custom patterns and exotic hardwoods

Manipulating around fireplaces, closets, counters, and cabinets

Proper subfloor and slab preparation

Measuring to provide space for glue or nails

Joist repair

Improper installation can cause wood floors to crack, bow, warp, split, or shrink over time. You also risk damaging wiring or plumbing in the process. If you know the risks and feel up to the task, start with a more forgiving type of hardwood that's easier to fix, such as engineered wood, floating floors, or click-and-lock tiles.

How to Save on Hardwood Flooring Costs

There are plenty of ways to reduce the cost of hardwood flooring installation without sacrificing the quality of your floors. Here are a few tips:

Here are a few tips:

Think beyond looks: Install a less expensive wood species, grain, thickness, or grade.

Refinish, don't replace: It costs much less to restore hardwood than to replace it.

Get multiple quotes: Get at least three contractor quotes to compare prices.

Install prefinished wood: Trade higher up-front costs for lower labor costs.

Rip up your own carpet: DIY carpet disposal is less risky and can help cut labor costs.

DIY engineered wood: Engineered wood is simpler and less costly to install and repair.

Break up the project: If you can't afford to redo your whole house, start by installing new floors in one or two rooms.

Audrey Bruno contributed to this piece.

Frequently Asked Questions

Hardwood floors are expensive, but they are also incredibly durable and can last decades with proper care. Along with being long-lasting, hardwood floors can give you an incredible ROI—up to 55% on average. Most homeowners find hardwood floors worth the initial investment so keep that in mind when deciding which way to go.

Along with being long-lasting, hardwood floors can give you an incredible ROI—up to 55% on average. Most homeowners find hardwood floors worth the initial investment so keep that in mind when deciding which way to go.

Hickory, red oak, white oak, and Brazilian walnut are among the most durable wood flooring options. Teakwood is extremely durable and known as one of the hardest woods. It will hold up against weather and sunlight, but it is costly and can be difficult to source. Keep durability in mind when installing floors for high-traffic areas in your home.

Over time, hardwood floors can lose their shine, meaning you’ll need to refinish them. Refinishing not only keeps them looking great, but it protects your floors from scratches as well. You should refinish your hardwood floors every 10 to 20 years.

You also need to clean your hardwood floors regularly and use the right tools to do so. Hardwood and humidity don’t mix, so you should never wet mop or bleach your floor boards. Instead, sweep, dry mop, or vacuum the hardwood floors to keep them sparkling.

Instead, sweep, dry mop, or vacuum the hardwood floors to keep them sparkling.

Ready to get a quote for your project?

Answer a few questions, compare reviews, and choose the pro you want.

Recommended Articles

How Much Does It Cost to Rent a Floor Sander?

By C.E. Larusso • February 16, 2022

4 Hardwood Plank Sizes and How to Use Them in Your Space

By Gemma Johnstone • July 6, 2021

Hardwood Floors Offer Modern Beach House Style

By Rod Lorenz of Ralph's Hardwood Flooring Co. • June 15, 2021

Prices for laying a parquet board per m2 - the cost of installing a parquet board with glue in Moscow

The cost of laying a parquet board per square meter will please you very much. We don't do cheats. When confirming the order, we draw up an accurate estimate, which does not change during work. The price of laying a parquet board in Moscow is calculated individually, based on the selected materials, the area of \u200b\u200bthe room and the complexity of the work.

Parquet board is a natural floor covering that consists of several layers of wood glued together. The top most valuable layer is called veneer, it is about 3-4 mm thick and is usually made from expensive and rare woods.

The veneer can be 1, 2 and 3-strip, the last two options consist of dies glued together, which create an imitation of piece parquet.

PRICES

for laying boards

| Service | Price |

|---|---|

| 1. Underlay deck | 50m2 |

| 2. Laying parquet board - floating | 450m2 |

| 3. Floating installation (DIAGONAL) | 500m2 |

| 4. Laying parquet board with adhesive (STRAIGHT) | 550m2 |

5. Laying parquet board with adhesive (DIAGONAL) Laying parquet board with adhesive (DIAGONAL) | 690m2 |

| 6. Skirting board assembly (Plastic) | 180pg/m |

TERMS

FOR INSTALLATION

| Area | Without plywood | From plywood |

|---|---|---|

| up to 15 M 2 | 1 day | 1-2 days |

| 15-25 M 2 | 2-3 days | 3-4 days |

| 25-40 M 2 | 3-4 days | 4-5 days |

| 40-55 M 2 | 4-5 days | 5-6 days |

| 55-70 M 2 | 5-6 days | 6-7 days |

| Over 70 M 2 | from 5 days | from 7 days |

The lower part consists of one or more layers, made from inexpensive and soft wood. All layers fit together perfectly and are glued perpendicular to each other. Using this method, their size does not change throughout the entire period of operation, even if the humidity in the room is increased or there are temperature fluctuations in winter or summer. The quality and price of the material are directly proportional to each other. The higher the cost, the better the quality.

All layers fit together perfectly and are glued perpendicular to each other. Using this method, their size does not change throughout the entire period of operation, even if the humidity in the room is increased or there are temperature fluctuations in winter or summer. The quality and price of the material are directly proportional to each other. The higher the cost, the better the quality.

The price of a board is affected by the following factors:

- The size of the plates

- Number of strips

- Number of layers (depending on thickness)

- Wood species of the top expensive layer

- Tree view of the bottom layer

- Veneer type

- Veneer cutting method

- Veneer Heat Treatment

- Type of top layer protective coating.

RECOMMENDATIONS

OUR TECHNOLOGY

- High-quality base

- Substrate from 2 to 4 mm

- If glued only on strong glue

- The service life of the docks before the first grinding is 15 years.

Leave a request

And we will call you back

Technologist Alexey +7 (968) 738-54-60

within an hour we will contact you!

Laying

parquet boards

in a straight line from 450 m2

diagonal from 500 m2

adhesive method from 550 m2

PRICES for works

PER M2

| Service | Old price | Price RUB |

|---|---|---|

| 1. Screed primer | 100 rub/m2 | 50 rub/m2 |

| 2. Solid board decking with adhesive SPAX screws (COATED) | 1050 rub/m2 | 950 rub/m2 |

| 3. Solid board decking with SPAX self-tapping screws (UNCOATED) | 900 rub/m2 | 800 rub/m2 |

| 900 rub/m2 | 850 rub/m2 | |

5. Floorboard installation, floating Floorboard installation, floating | 500 rub/m2 | 450 rub/m2 |

| 6. Floating parquet flooring (DIOGANAL) | 650 rub/m2 | 500 rub/m2 |

| 7. Installation of parquet boards with glue (DIRECT) | 700 rub/m2 | 550 rub/m2 |

| 8. Installing the parquet board with glue (DIAGONAL) | 800 rub/m2 | 690 rub/m2 |

| 9. Installing curb | 500 rub/m2 | 400 rub/m2 |

| 10. Installation of frieze | 950 rub/m2 | from 850 rub/m2 |

11. French Tree French Tree | 1950 rub/m2 | 1500 rub/m2 |

| 12. Module deck | 1950 rub/m2 | 1200 rub/m2 |

| 13. Artistic parquet flooring | 3500 rub/m2 | 2500 rub/m2 |

| 14. Complex parquet laying (braided, sheremetyevka) | 950 rub/m2 | 850 rub/m2 |

| 15. Diagonal Squares | 1200 rub/m2 | 1100 rub/m2 |

| 16. Insert "Sockets" | 4500 rub/m2 | 3400 rub/m2 |

Price list for additional work

| Service | Price | |

|---|---|---|

| Parquet floor removal | | 500 rub/m 2 |

| Removing solid board | | 550 rub/m 2 |

| Linoleum removal | | 40 rub/m 2 |

| Laminate removal | | 50 rub/m 2 |

| Filling screeds up to 20 mm | | 300 rub/m 2 |

| Screed up to 40 mm | | 400 rub/m 2 |

| Screed grinding with diamond disc | | 249 rub/m 2 |

| Base cleaning | | 50 rub/m 2 |

| Epoxy primer application | | 200 rub/m 2 |

| Multimoll flooring | | 149 rub/m 2 |

| Plywood cutting | | 60 sheet |

| Lifting plywood in an elevator | | 99 sheet |

| Parquet lifting | | 99 pack |

Prices for skirting board installation

| Service | Price | |

|---|---|---|

| Removing the skirting board | | 50 rub/m 2 |

| Installation of wooden skirting up to 50 mm high | | 200 rub/m |

| Installing a wooden skirting board 50 to 70 mm high | | 230 rub/m |

| Installing a wooden skirting board 70 to 90 mm high | | 250 rub/m |

| Installing a wooden skirting board 90 to 110 mm high | | 300 rub/m |

| Installing a wooden skirting board over 110 mm high | | 350 rub/m |

| Baseboard varnishing | | 50 rub/m |

| Installation of plastic skirting board | | 150 rub/m |

| Installation of euro plinth with clips | | 450 rub/m |

| Installation of flexible polyurethane skirting | | 550 rub/m |

Features of surface preparation for laying work.

Before you start laying parquet boards in Moscow, the flooring must be carefully primed. If it can form moisture, then it is simply necessary to prime the surface well with epoxy or polyurethane two-component primers before starting all work.

If this is not done, then you will not be able to cope with the impact of liquid on your parquet. The substrates that isolate from the liquid, on the contrary, will begin to accumulate water and its excess content will begin to flow into the room, which will contribute to the formation of fungus.

In which direction should the board be laid on the plywood?

Recommended to lay perpendicular to windows. It can be a canvas or have joints - it doesn't matter. When using the floating method of laying a parquet board, all the joints between the pieces are hidden under small overlays, and with the adhesive laying technology, special cork compensators are mounted. The direction of laying, the price per m2 of which we have is quite affordable, depends entirely on the placement of window openings in the room, almost always the slabs are located perpendicular to the window.

The parquet board is laid in two different ways:

It creates an excellent acoustic effect on glue, such a floor does not loosen from temperature and humidity changes, it lasts much longer, it can be scraped up to 3 times. Laying a board on an underlay is much faster and cheaper than using glue, it is much easier to dismantle it after the expiration of its service life to install new material.

If you have purchased an expensive and very beautiful parquet board, do not skimp on the work of craftsmen. Buy high-quality expensive glue or seek advice from my qualified specialists. Here you can get acquainted with the prices for laying.

If you do not plan to spend a lot, then do not buy expensive options, lay an ordinary inexpensive board in a floating way.

Cost of laying a parquet board per square meter for glue and technology

Laying a parquet board (the cost of work depends on the area of the room) is allowed only on a perfectly flat surface. Glue will stick the dice to any base. However, if the coating has defects, then they must be eliminated. Screeds are usually primed and leveled using a self-leveling floor, and scraping is carried out on wooden surfaces.

Glue will stick the dice to any base. However, if the coating has defects, then they must be eliminated. Screeds are usually primed and leveled using a self-leveling floor, and scraping is carried out on wooden surfaces.

If parquet boards are laid on wood flooring, then special pins are driven into the grooves of the boards. This is done so that the board adheres better to the surface. If it is not possible to do this, then everything that is heavy is placed on the boards. You can simply collect water in five-liter bottles and put it on the parquet.

The cost of laying on the underlay and the technology of work

The floor is being prepared, then the underlay is mounted, which is glued with adhesive tape. Laying a parquet board, the price for it varies depending on the area of the room, is carried out in strict accordance with the instructions. A gap of 1 cm is left between the wall and the floor covering, in case of expansion of the board due to temperature rise and humidity fluctuations. If there are pipes in the floor covering, then a hole is carefully drilled in the board, which (at the request of the customer) is sealed with a special insert. After completion of all work, the plinth is installed.

If there are pipes in the floor covering, then a hole is carefully drilled in the board, which (at the request of the customer) is sealed with a special insert. After completion of all work, the plinth is installed.

How to choose an underlay for floating installation?

When performing professional underlayment, the first step is to choose the material for the underlayment. There are 5 types of substrates: flexible ones are rolled up, and rigid ones are made in rectangular or square shape. At first it may seem that even an inexperienced person can choose a substrate, but everything is not so easy here. There is a certain scheme for selecting the substrate for a particular room. Not all of them protect the flooring from moisture, which means that you will still have to spend money on plastic wrap.

Underlays can also be used to slightly isolate the room from sound or smooth out existing surface irregularities. Under the last two versions of the substrates, it is recommended to lay a polyethylene film to protect against moisture; in the first three options, its use is not necessary.

Underlay types:

- Polyethylene foam (high waterproofing).

- With foam balls placed between two layers of foil for excellent waterproofing.

- Rubber and bituminous backing with good moisture protection.

- Natural cork backing is not waterproof.

- Expanded polystyrene (extruded) in mats does not protect the floor from moisture

- Interesting article how to install modular floor

Leave a request

And we will call you back

Technologist Alexey +7 (968) 738-54-60

within an hour we will contact you!

Parquet installation | parquet board

- home

- Floor installation and laying of floor coverings

Telephone

Why us

Fixed price

Price is fixed and does not change during the process

Warranty up to 5 years *

Did something go wrong? We will come, fix it

German equipment

We use the most accurate equipment

Official contract

We will write everything down and take into account

Pay attention! You lose the extended warranty if you order styling not from us!

Why? Everything is simple!

Each floor covering has its own characteristics and laying restrictions! Our specialists regularly undergo advanced training from manufacturers with whom we cooperate! We provide an extended warranty up to 5 years *

Installation by private craftsmen

- Before laying do not measure the parameters of the base

- Using a tool that is not designed for laying parquet

- Material overrun

- Do not leave deformation gaps

Installation by experienced craftsmen

- Use professional tools

- Mandatory verification and preparation of the base is carried out

- Compliance with the technological process

- Work is carried out in compliance with the requirements of manufacturers

- Work experience of specialists - from 3 years (with certification from manufacturers)

4 easy steps to perfect floor laying

Technologist visit

Estimate in 5 minutes

Negotiation of conditions and signing of the contract

Laying

Our works

Before

After

Before

After

Before

After

Before

After

Departure of a technologist to assess the quality of the base

Floor installation and flooring installation

Telephone

By clicking on the "Submit request" button, I consent to the processing of personal data and agree to the policy privacy.

Installation cost

-

Laying laminated, PVC, SPC coatings on a substrate diagonally and parallel to the walls (minimum preparation of the base, laying)

from 690 r/m2

Laying laminated, PVC, SPC coatings on a Christmas tree pattern substrate (minimal preparation of the base, laying)

from 1440 r/m2

-

Laying parquet and engineered boards with interlocks in a floating way diagonally and parallel to the walls (minimum preparation of the base, laying)

from 945 r/m2

Laying of parquet and engineered boards with a locking joint in a floating way pattern Christmas tree (minimum preparation of the base, laying)

from 1546 R/m2

Gluing parquet and engineered boards on the screed diagonally and parallel to the walls (minimum base preparation, priming, laying)

from 1380 r/m2

Bonding parquet and engineered boards on a screed pattern (Christmas tree, French Christmas tree, square, wicker) (minimal preparation of the base, priming, laying)

from 2330 r/m2

Bonding parquet and engineered boards on a plywood layer pattern (Christmas tree, French Christmas tree, square, wickerwork) (minimal preparation of the base, priming, laying plywood, sanding the laid plywood, laying the board)

from 3110 r/m2

-

Bonding a solid board to a plywood base diagonally and parallel to the walls (minimum preparation of the base, priming, laying plywood, sanding the laid plywood, laying the board)

from 2370 r/m2

-

Bonding coated piece parquet on site (deck, tree, square) diagonally and parallel to the walls (minimal subfloor preparation, priming, laying plywood, sanding laid plywood, laying parquet, sanding and puttying parquet, varnishing)

from 4740 r/m2

Bonding coated strip parquet on site (deck, tree, square) diagonally and parallel to the walls (minimal subfloor preparation, priming, laying plywood, sanding laid plywood, laying parquet, sanding and puttying parquet, oiling)

from 4175 R/m2

-

Plastic plinth

from 448 r/p.

m

m Veneered, MDF, Laminated plinth

from 560 r/p.m.

Veneered, Massive plinth with sectors

1680 R/p.m.

Massive plinth

from 737 r/p.m.

Forming the junction of the plinth

from 540 r/pc.

Making additional corners

from 540 r/pc.

-

Leveling the concrete base by grinding up to 5mm

from 571 r/m2

Leveling the base with liquid putty horizontally up to 5mm

from 630 R/m2

Installation of a cork strip (without tinting) in the junction area with convectors and other floor coverings

from 560 r/p.

m

m Installation and tinting of a cork strip in the area of adjacency with convectors and other floor coverings

from 785 r/p.m.

Installation and tinting of a cork strip with milling around the perimeter of the room

from 2688 R/p.m.

Milling of the floor covering in the area adjacent to convectors and other floor coverings

from 560 r/p.m.

Sealing gaps in the junction area with convectors and other floor coverings

from 785 r/p.m.

Sealing abutment with milling around the perimeter of the room

from 2688 R/p.m.

Good to know

When buying parquet, it is important to remember that it is absolutely not recommended to use it immediately after delivery. For at least a week, the materials should lie down in the place where the work will be done. Only during this time will the humidity of the room and the parquet board even out.

For at least a week, the materials should lie down in the place where the work will be done. Only during this time will the humidity of the room and the parquet board even out.

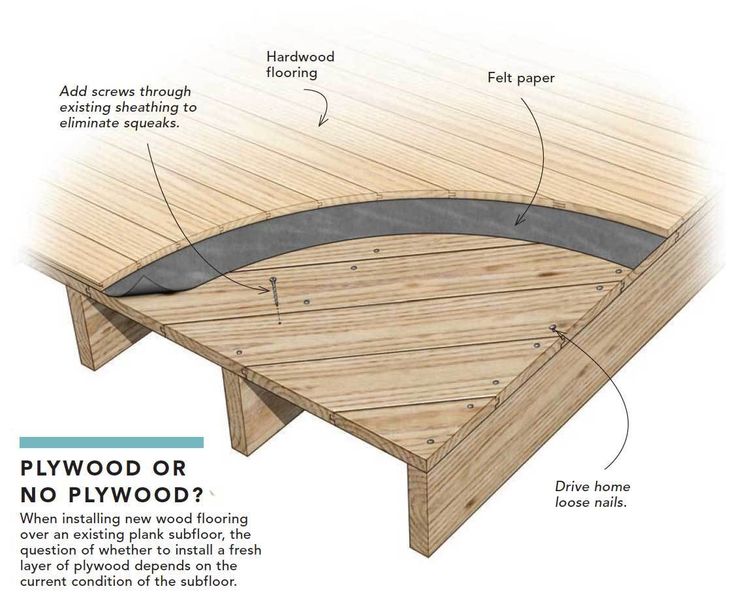

Before laying parquet, it is necessary to assess the strength of the substrate; if it is low, then it is better to start by laying a separating substrate. The process of laying parquet

The process of laying parquet

Modern parquet board is a ready-to-install material. It does not need to be oiled or varnished and does not need to be sanded. Under the law, laminate and parquet boards, as well as solid wood boards, are not required to undergo certification, but there are still some rules:

Methods for laying parquet boards

1. Floating method. The basis of laying is the castle connection.

2. Hard fastening method, in which the board is glued to the base.

Consider how to install parquet boards in more detail

Floating floor method. Individual parquet boards are not fixed to the base, but are fastened with a locking joint. A substrate is placed between the base and the parquet floor, on which the boards lie freely, assembled into a single layer.

The advantages of this method are high laying speed and reduced labor costs. The laying technology is so simple that often such parquet is laid on its own. The finished work, if necessary, can be disassembled and reused parquet board.

The floating floor method has its drawbacks :

- when the floor begins to make sounds under steps or even characteristically creak;

- if the lock connection is deformed, then the whole structure ceases to be reliable;

- When parquet is used for a long time, sooner or later the question of its restoration arises.

Floating parquet cannot be sanded down for restoration.

Floating parquet cannot be sanded down for restoration.

To get the best possible performance when laying parquet using the floating method, the following recommendations must be strictly observed:

- A separating diaphragm must be used for any base. A polyethylene film with a thickness of 0.2 mm or 200 mKr is used as a membrane, it must be overlapped. Before laying, the film should be removed to the walls up to 50 mm, and at the end of work, but before installing the skirting boards, it should be cut to 10 mm. The next step is the laying of a sound-absorbing substrate 2-3 mm thick, it does not need to be glued;

- The second important recommendation is the creation of expansion gaps between the floor covering and walls, as well as in doorways. This gap should not be less than 10 mm. If the room is large, then the expansion gap should be maintained along the entire perimeter of the floor, amounting to 1.5 mm per 1 meter along the width and length of the floor.

With rigid fastening of parquet board , each plank is glued to the screed and fixed with weights while the glue dries.

The main advantage of a rigid mount is its high reliability. If such a parquet needs repair, then it will not be too difficult. Parquet laid in this way is very comfortable and does not creak. When laying, there is no need to use thresholds (for connection) between rooms.

There are some minor drawbacks. This method of laying is more time consuming, takes more time, requires a certain professionalism and, accordingly, is more financially costly.

Engineering board

This board has a special structure, it has a plywood base. This imposes certain nuances on the rules for its installation - it should always be only an adhesive method. If you use the floating method, then cracks and swelling are inevitable. An engineering board can be laid on a screed or on plywood sheets. In the latter case, for better fastening, you can use self-tapping screws.