Refacing cabinets with laminate

Can You Reface Laminate Cabinets?

Yes, laminate cabinets can be refaced as long as the cabinet boxes are in good shape. But if the cabinet boxes are weak or damaged, you may need to replace your cabinets altogether.

In this article, we’ll go over:

- What’s included in a refacing

- Whether to DIY reface or call in a professional

- Cabinet refacing finish options

- When it’s time to replace your cabinets

Need a cabinet refacing quote? Contact us online or call 480-641-9611 and we’ll send one of our experts to your home for a free consultation.

What’s included in a refacing

With a cabinet refacing, a professional will:

- Remove existing cabinet doors and drawer fronts. With a refacing, you’ll get brand new doors. The contractor will also strip and sand your cabinet boxes to prepare them for the new finish of your choosing.

- Apply the new finish. The contractor will coat your cabinet boxes in the new finish and apply the same finish to your new doors and drawer fronts.

- Install new doors and drawer fronts. The contractor will also install any upgraded hardware you chose, like new cabinet pulls or soft-close hinges or drawer tracks.

The cabinet refacing process usually takes about a week and may differ by a few days, depending on which company you go with.

DIY vs professional cabinet refacing

The cost of a professional cabinet refacing can range between $5,000 and $15,000. The cost of the project will increase with:

- The size of your kitchen or bathroom and number of cabinets

- Higher quality materials and finishes

- Cabinet or hardware upgrades (like high-quality hinges, new pulls, soft-close drawer tracks, etc.)

- More experienced and better quality contractors

Wondering if you can do the job yourself and save some money?

You might save a little money upfront with a DIY cabinet refacing, but we wouldn’t recommend doing the job yourself.

Why? Well, a professional cabinet refacing includes:

- Better quality finishes and professional guarantees.

Professionals will have access to a range of high-quality finishes you likely can’t find at home improvement stores. For example, Cabinet Coatings uses only the strongest finishes to reface cabinets. They’re so durable, we back our finishes with a 5-year guarantee. If they chip, crack or fade before then, we’ll come back and redo the work at no cost to you.

Professionals will have access to a range of high-quality finishes you likely can’t find at home improvement stores. For example, Cabinet Coatings uses only the strongest finishes to reface cabinets. They’re so durable, we back our finishes with a 5-year guarantee. If they chip, crack or fade before then, we’ll come back and redo the work at no cost to you. - An inspection to catch structural problems. A professional will inspect your cabinets before refacing them to make sure they’re in good enough shape to be refaced (i.e. they’re not molding, warped or rotting from water damage, etc.). You may have to replace the cabinets if they’re in too bad of shape.

- A quick turnaround time. Even if you know what you’re doing, refacing the cabinets yourself could easily take several weeks to a month. Most professionals can get the job done between 3 and 5 days if you can plan ahead.

Cabinet refacing finish options

In terms of choosing a finish to match the look and feel you want for your cabinets, your options are virtually endless.

But when choosing a finish type, you essentially have 3 options:

- Laminate: You’re probably pretty familiar with the pros and cons of plastic laminate cabinets. To reface cabinets, the laminate is essentially melted on to provide a water-resistant seal. While you have a lot of color and texture options, the finish tends to start chipping after just a few years.

- Veneers: Veneers are super thin sheets of wood that are adhered to your cabinets. Veneers come in a range of tree types—maple, oak and cherry, to name a few—and can be stained to just about any color you want. Like laminate, veneers can easily chip or peel not long after it’s applied. (That’s just one of many reasons we’d never use veneers on your cabinets.)

- Water-borne coating: Some companies, like Cabinet Coatings, prefer to use an ultra-durable coating (available in almost any color) that’s sprayed onto the cabinets. These coatings are waterproof and strong enough to last years.

To get the most out of your cabinet refacing, we recommend going with a durable finish that will make your refacing last as long as possible.

To learn more about how long a typical refacing lasts, visit our blog “How Long Does Refacing Last?”

When it’s time to replace your cabinets

You’re better off replacing instead of refacing your kitchen cabinets if:

- Your cabinet boxes are badly damaged. If your cabinet boxes are warped or waterlogged, it’s probably time to replace them. Refacing damaged cabinet boxes would shorten the life of your refacing, since the damage would start showing its ugly face again soon after the job is done.

- You want to update your cabinet layout. If you find yourself needing extra storage or more counter space, replacing your cabinets will allow you to design a cabinet layout customized to your needs.

- You’re making other major changes to your kitchen or bathroom. If you’re doing a complete remodel of the kitchen or bathroom—like replacing flooring, appliances or fixtures—you may want to consider replacing the cabinets as well, instead of paying for 2 separate projects.

Learn more about when to replace your cabinets in our blog “Reface or Replace: Which is Best for My Cabinets? An Arizona Pro Explains.”

Need a quote to reface your laminate cabinets?

Schedule an appointment online or call us at 480-641-9611. One of our finishing pros will give you a free in-home or virtual consultation and same-day, upfront quote. We’ll help you find the right finish to reface your laminate cabinets and refresh your home.

Chuck Derouen

For 20 plus years chuck has been helping homeowners make decisions on how to bring new life into their kitchens. Most homeowners know what they want but don’t know how to communicate it. When chuck does the in-home consultation he draws from the client and uses his expertise to help them bring their imagination to life (achieve the look they imagine.) Chuck dubs himself a “professional mind maker upper.”

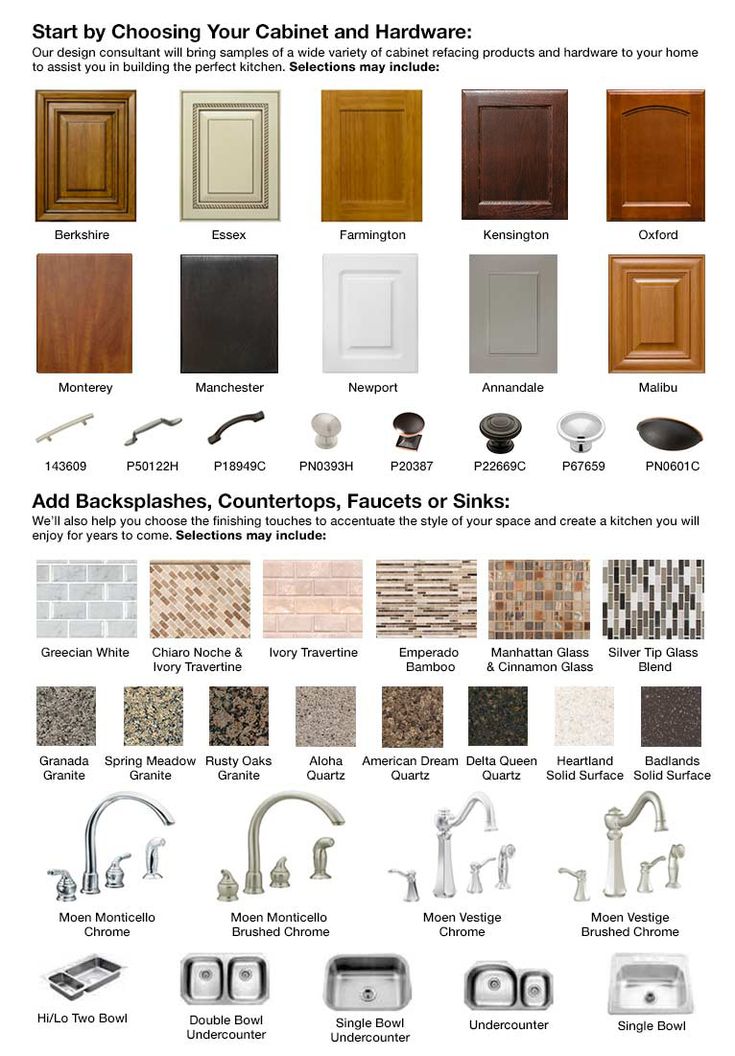

Laminate & Wood Cabinet Refacing Options

Choose from hundreds of style and color possibilities! Displayed here are Kitchen Magic’s ‘top picks’ – a sampling of our most popular cabinet refacing colors and styles in both laminate – and natural wood!

Laminate Refacing Colors and Styles

Laminate is highly durable and functional for just about any interior surface. A long history of advances in laminate design and craftsmanship is built into our refacing process. Our most popular laminate colors come with a Lifetime of Homeownership Warranty, your design consultant can provide additional details.

A long history of advances in laminate design and craftsmanship is built into our refacing process. Our most popular laminate colors come with a Lifetime of Homeownership Warranty, your design consultant can provide additional details.

New

Frosty White

New

Chestnut

New

Colonial Blue

New

Satin Black

Wood Refacing Colors and Styles

Displayed here are just a small sampling of our most popular wood cabinet refacing colors and styles.

Choose from hundreds of wood grain, stain and glaze combinations to create that one of a kind look that you will be proud to make your own. Our wood refacing material is of the highest quality and finish. Each stain and glaze is applied by hand to achieve a rich, deep finished look. Our ever-expanding palate of colors and treatments providevirtually endless possibilities! Many natural characteristics present in wood may affect how stain is absorbed and will cause mild color deviations that will make your refaced cabinets one of a kind.

Our wood refacing material is of the highest quality and finish. Each stain and glaze is applied by hand to achieve a rich, deep finished look. Our ever-expanding palate of colors and treatments providevirtually endless possibilities! Many natural characteristics present in wood may affect how stain is absorbed and will cause mild color deviations that will make your refaced cabinets one of a kind.

New

Bamboo Harvest

New

Cherry Cordovan on Cherry

New

Cherry Harvest with Caramel Glaze

New

Natural Cherry with Glaze

New

Harvest Gold on Maple

New

Maple with Nutmeg Stain

New

Red Oak Honey Pewter

New

Product Title

Looking for More Cabinet Refacing Options?

Please ask your representative at time of estimate to show you additional color and style collections. The ideal way to view samples is in the comfort and lighting of your very own kitchen. Actual color may differ from what appears on your screen due to variations in computer monitors and other factors. You may request a sample swatch of the desired species, stain or treatment prior to placing an order.

The ideal way to view samples is in the comfort and lighting of your very own kitchen. Actual color may differ from what appears on your screen due to variations in computer monitors and other factors. You may request a sample swatch of the desired species, stain or treatment prior to placing an order.

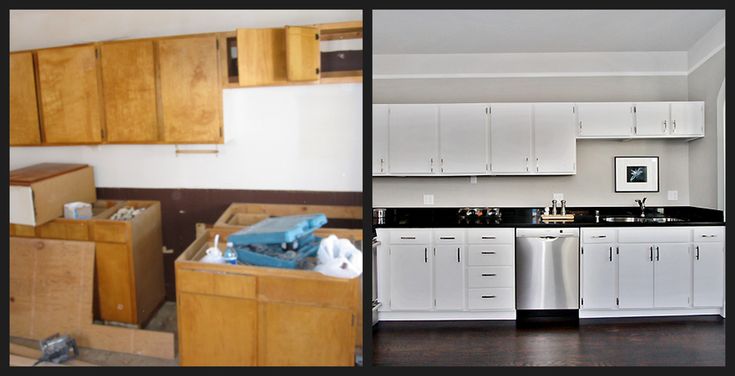

Kitchen Magic offers professional kitchen remodeling services including cabinet refacing. We work on the existing layout of your kitchen to create a renewed and updated look that is more relevant to the current times. If you are ready to transform the appearance of your kitchen cabinets, schedule a free design consultation with our designers today.

Understanding Cabinet Refacing Options

We offer an exclusive cabinet refacing method that is performed by certified, experienced installers. The process consists of a total of 4 main steps that will resurface, reinforce, and renew your cabinetry. The first step is to remove all your existing cabinet doors before we can prepare the surfaces for refacing. This is followed by a double-lamination process that utilizes quality 1/4" plywood that gets bonded to the frames of your cabinets. Subsequently, a layer of high-grade wood or laminate will be applied to reinforce the structure. This is followed by the final step of installing new doors and drawer fronts with the option of adding new drawer boxes. The color choices that our designers recommend will help to ensure that your existing structure can match exactly with the new layers and accessories.

This is followed by a double-lamination process that utilizes quality 1/4" plywood that gets bonded to the frames of your cabinets. Subsequently, a layer of high-grade wood or laminate will be applied to reinforce the structure. This is followed by the final step of installing new doors and drawer fronts with the option of adding new drawer boxes. The color choices that our designers recommend will help to ensure that your existing structure can match exactly with the new layers and accessories.

Benefits of Cabinet Refacing

The main benefit of working with Kitchen Magic is to help you save on at least 50% of costs. Cabinet refacing works on the existing structure of your cabinets, so the costs of new installations are not required. The entire cabinet refacing process is also not as time-consuming as new installations as our craftsmen work on the existing foundation of your cabinets and you can enjoy your refaced cabinets within only 5 days. This makes cabinet refacing a much eco-friendlier option which still produces amazing results that last for an extended period of time.

Installation Options for Cabinet Refacing

Kitchen Magic reinforces the existing frames of your cabinets through the use of durable 1/4" plywood before applying a veneer of maintenance-free laminate or real wood. Our professional craftsmen make prior precise measurements to ensure a good fit can be achieved for a seamless application. The color options that we recommend will help to ensure that your choice of colors will match the existing structure of your cabinets for a flawless transformation along with the new knobs, pulls, hinges, and molding.

Why Work with Kitchen Magic for Cabinet Refacing?

Kitchen Magic is a BBB-accredited business with an A+ rating. We have been rated an average of 4.5 on Google ratings and 4.7 on Houzz and HomeAdvisor. Our craftsmen are all fully qualified and trained to perform remodeling services to offer incredible transformation results at highly attractive prices. Our countless testimonials from past clients show the top-notch quality that our team always delivers in a timely fashion so you can expect to work with professionals with years of industry expertise. We also have a team of designers with whom you can work with to obtain design advice and insight that can help you to make suitable choices that let you achieve optimum results while saving on hefty costs.

We also have a team of designers with whom you can work with to obtain design advice and insight that can help you to make suitable choices that let you achieve optimum results while saving on hefty costs.

MDF and chipboard cladding: which facade is better?

Home » Articles

The most popular materials used in the manufacture of furniture are chipboard and medium-density fiber coating, simply speaking, chipboard and MDF. They have earned their popularity due to their durability, practicality, affordable price and durability. Chipboard and MDF cladding can be made from both natural materials, such as natural veneer, and synthetic materials, such as laminate or melamine. nine0003

Veneer - the beauty and style of your furniture

Natural veneer is considered to be the most luxurious and solid material for facing. It is made from a thin cut of wood of such species as oak, walnut, alder and others. A lacquer coating is necessarily applied over the veneer, which not only protects it from damage, but also gives the furniture an expensive look, as if it were made of solid wood. For these purposes, polyurethane or acrylic varnishes are used. Polyurethane varnishes are applied by spraying, but when applying acrylic varnishes, the roller method is used. In addition, the surface of the veneer can be painted before varnishing, or decorative images can be applied. nine0003

For these purposes, polyurethane or acrylic varnishes are used. Polyurethane varnishes are applied by spraying, but when applying acrylic varnishes, the roller method is used. In addition, the surface of the veneer can be painted before varnishing, or decorative images can be applied. nine0003

The main advantage of veneer is its high level of environmental friendliness. The price of veneered furniture is much lower than the cost of similar products made from solid wood, but it is still quite an expensive coating. However, in this case, the quality and appearance clearly justify the investment.

Furniture with veneered veneer will last quite a long time with proper use and good care. To maintain the proper appearance and condition of veneered furniture, it is necessary to wipe it with a dry cloth without the use of polishing agents that contain alcohol or solvent, avoid large temperature fluctuations and a strong increase in humidity. nine0003

Laminate and melamine - profitable and effective

Laminate is one of the most common synthetic types of furniture lining. Such a coating is applied to chipboard panels under the influence of pressure and high temperature or by laminating, when hard paper-resin films are glued onto the panel. This type of cladding has both its pros and cons. The latter include a relatively short period of operation. As for the strengths of the laminate - the material does not fade in the sun and it is enough to simply remove various types of pollution from it. nine0003

Such a coating is applied to chipboard panels under the influence of pressure and high temperature or by laminating, when hard paper-resin films are glued onto the panel. This type of cladding has both its pros and cons. The latter include a relatively short period of operation. As for the strengths of the laminate - the material does not fade in the sun and it is enough to simply remove various types of pollution from it. nine0003

Speaking about this type of furniture cladding, like melamine, it is worth remembering that despite the affordable price, this coating has a fairly diverse color palette. But at the same time, melamine is very thin, which does not allow hiding all kinds of defects. It repeats the shape of the surface one to one, so that any dents and scratches of the base material obtained during the production process will be clearly visible.

Another artificial substitute for natural veneer is PVC film applied to MDF by means of a vacuum press. It is thicker than melamine, which makes surface imperfections less noticeable, while the range of available shades is quite diverse. An important advantage of this type of cladding is the possibility of designing profile products. The disadvantage is that the likelihood of delamination increases over time. nine0003

An important advantage of this type of cladding is the possibility of designing profile products. The disadvantage is that the likelihood of delamination increases over time. nine0003

Furniture manufacturers offer customers a wide range of materials, knowledge of the pros and cons of which will help to make the right choice. When purchasing furniture from a manufacturer, whether it is a serial or exclusive model, you can be sure of its reliability and quality.

Consent to the processing of personal data

Personal data processing policy

We accept urgent orders for the manufacture of sliding wardrobes and furniture to order from 5 days. Contact us right now. nine0031 COUPE CLOSETS IN MOSCOW AND MOSCOW REGION FROM THE COMPANY 1001CABINET: EVERYTHING STARTS WITH A CALL TO US.

We accept MIR, Visa, MasterСard

Call

+7 (495) 120-23-72

Working hours:

weekdays - from 9:00 to 21:00

weekends - from 9:00 to 20:00

Call the measurer, upon conclusion of the contract , he will calculate the furniture for FREE.

Within the Moscow Ring Road, departure is free, for residents outside the Moscow Ring Road, check with consultants for the cost of departure. The order and production of wardrobes, wardrobes, hallways, bedrooms and other custom-made furniture should always begin with a call to a specialist measurer

Information about legal entity

Full name of the organization:

LLC Aurora

OGRN: 1127746405940

TIN: 7701958725

Write to the director

90,000 turnkey laminate in Moscow at a low price, photos of the company BalconlineRequirements balcony (loggia)

In order for the coating to serve for a long time, it is recommended to carry out preparatory work in the room before installation. The loggia and balcony, unlike other rooms, take on the maximum exposure to ultraviolet radiation. Therefore, use only a high quality product that does not change its appearance in the sun. nine0003

The product does not tolerate moisture well. From dampness, it swells, loses its shape, and eventually collapses. Before finishing work, glaze the room and protect it from moisture penetration through the roof and other components. If it is not possible to create a dry room, it is recommended to use a plastic base.

From dampness, it swells, loses its shape, and eventually collapses. Before finishing work, glaze the room and protect it from moisture penetration through the roof and other components. If it is not possible to create a dry room, it is recommended to use a plastic base.

Insulation plays an important role. Severe frost and sudden temperature changes lead to deformation of the structure. It is not recommended to lower the temperature below +5 degrees. Insulation should also be used for sound insulation, since the laminate transmits sound. If the balcony is not glazed, then such a sheathing cannot be installed. nine0003

If you cannot create such conditions, then it is better to look for other materials that are more resistant to humidity and can be used in a wide temperature range.

Even if it is not possible to fulfill all the requirements, it is permissible to finish the loggia in this way. At the same time, pay more attention to the selection. You need a high-quality moisture-resistant product of sufficient strength.

Laminate Disadvantages

Laminate creates a cozy atmosphere and allows you to implement all design ideas during renovation. However, before buying it, you need to make sure how appropriate it is in your case. The main disadvantages are:

- instability to sudden changes in temperature;

- moisture sensitive;

- for mounting on an uneven surface, it is important to make the frame correctly, which takes up useful space.

For sheathing, take products of class 32-33. It can be mounted in rooms with a high level of humidity. It retains its appearance for a long time under the influence of direct sunlight and is resistant to aggressive environments.

Before installation, it is recommended to allow the material to rest for several days. This adapts it to the microclimate and humidity level. nine0003

Installation options

The boards themselves have two types of connection:

- Lock. Each element is inserted into the groove of the other.

The disadvantage of this variety is the requirement for evenness of the surface. The slightest unevenness over time will lead to a divergence of the boards and the formation of cracks. At the same time, it is almost impossible to re-shift the site on the finished structure

The disadvantage of this variety is the requirement for evenness of the surface. The slightest unevenness over time will lead to a divergence of the boards and the formation of cracks. At the same time, it is almost impossible to re-shift the site on the finished structure - Click. They are connected with a hook, which is firmly snapped into place by joining the sheets to each other. Such a lock is easier to install. Fastening is carried out at an angle of 45 degrees, until it snaps into place. After that, the component is laid in the entire plane until it is even. nine0079

Can be covered with any type of laminate. For beginners, it is more convenient to use the second option, due to the ease of installation and long service life without the formation of cracks.

Laminate boards can be attached to the substrate in various ways:

- Adhesive. The method is similar to laying tiles. Glue is applied to the back of the panel, then it is glued to the surface.

To do this, you can use liquid nails. The advantage of this method is the preservation of elasticity after hardening, but the surface must be even. You can pre-level it with drywall. nine0079

To do this, you can use liquid nails. The advantage of this method is the preservation of elasticity after hardening, but the surface must be even. You can pre-level it with drywall. nine0079 - For special staples. They fit into the groove and do not interfere with the installation of the next element.

- You can conveniently fix it with self-tapping screws of a suitable size, but the attachment points will be visible, which spoils the overall picture.

Lathing must be installed on the front surfaces. Therefore, a combined fastening with glue and staples is often chosen.

Installing the batten

The batten is an important structural component. The strength of the finish depends on the correctness of its installation. For the construction, you can take a wooden beam. It is lightweight and inexpensive material. To ensure durability, a galvanized profile is used, but it is heavier and more expensive. Typically, such a frame is installed simultaneously with insulation, which fills the space between its parts. nine0003

nine0003

Before starting work, the evenness of the substrate is checked. If there are differences, then they are eliminated with plaster or moisture-resistant drywall. Large gaps are filled with mounting foam, which must be cut off after hardening. An antiseptic is applied to the floor, and then foil insulation is laid.

The bars are installed in 500-600 mm increments. Anchor dowels should be used for fastening. They will provide a strong fixation and are able to withstand high loads. Each bar must be leveled, differences are unacceptable. nine0003

Insulation is placed in the niches formed between the beams, which is pre-cut to size. The material for insulation is mineral wool or expanded polystyrene.

A base for fixing is made in the upper and lower parts of the structure. To do this, lay the boards at the joint with each other.

On the walls, additional vertical posts are added to the crate at a distance of 400 mm from each other. If you plan to lay the components vertically, then the structure is made in a horizontal direction. nine0003

nine0003

In order to make wooden battens last longer, it is recommended to treat them with an antiseptic solution for protection. If you are planning to decorate the ceiling, then the crate is also made there.

The installation technology of the metal profile crate is similar to the wooden version of the bars. It is necessary to select galvanized metal that is not susceptible to corrosion. During installation, it is necessary to focus on the extreme profiles. Often horizontal planks are made of wooden beams.

Laminate wall fixing

Tiles are laid horizontally or vertically. The choice of masonry depends on your preferences. You also need to focus on the size of the panel and the surface area. To increase the strength, fastening is performed on liquid nails and staples.

You don't have to cut all the blanks at once. Finishing the loggia with laminate, the walls of which are uneven, will lead to defects. The panel changes its size with temperature changes. Therefore, a gap of about 1 cm from the wall is made in the corners. This will give enough space for seasonal expansion. nine0003

Therefore, a gap of about 1 cm from the wall is made in the corners. This will give enough space for seasonal expansion. nine0003

For small areas, it is convenient to assemble several panels together on the floor and then fasten to the base. Regardless of the direction, work is carried out in the following sequence:

- A stop is placed under the board to avoid slipping under the influence of gravity.

- Adhesive applied on the back. For better adhesion, the adhesive is applied in a zigzag pattern.

- The element is pressed tightly with force.

- Staples are attached with small nails or self-tapping screws. They are on the inside, and the attachment points will not be visible. nine0079

- The next panel is installed as the previous one. It is important to press the boards tightly against each other so that there are no gaps.

Check each element with a level. This will avoid distortion when laying. A balcony with laminate on the wall looks beautiful, but it is important to do the installation correctly.

Floor installation

Concrete floors can be laminated in three layouts:

- Parallel to the window. This method visually expands the space, but increases the size of the joints. nine0079

- Perpendicular to window. This method reduces the visibility of joints, which gives the coating a one-piece appearance. This method increases the consumption of raw materials.

- Diagonal. Visually increases the space and is suitable for rooms of complex shape. However, the consumption of raw materials increases by a quarter.

Laying is carried out in several stages:

- Wedges are placed against the walls for spreading.

- Laying starts from the far side of the entrance. The first board is laid in the chosen way. nine0079

- Each next one is inserted into the groove until it clicks into place. Adjustment is carried out with a hammer with a bar or mallet.

- If the last row does not fit the whole board, then it is cut off.

- After installation, the expansion wedges are removed and the cavities between the floor and the wall are closed with skirting boards.

For comfortable walking on the floor in winter, you can install an electric underfloor heating under the floor.

Ceiling installation

Finishing the ceiling with laminate is a little more difficult, so this surface is sheathed at the beginning of the finishing work and then proceed to other parts. nine0003

Preferably, the ceiling part should be sheathed perpendicular to the window. Work is carried out on weight and short components are easier to mount. It is difficult for one to cope with the ceiling lining, so you need a partner.

As with walls, leave a technical gap in case of seasonal expansion. The panel is fastened with glue or liquid nails, and then fastened with brackets.

Laminate cladding is often used in apartments and private houses on the loggia. You can make it with your own hands after preparing the premises and strictly following the instructions during work.