How to put up drywall ceiling

Hanging Drywall on Ceilings - Fine Homebuilding

Fine Homebuilding Project Guides

Drywall

How-To

The first rule of drywalling: install ceilings first.

By Myron R. Ferguson

Save your back: When using a lift to install a cathedral ceiling, it’s easiest to hang the first panel at the peak and work your way down to the sidewalls.In a room that will have drywall attached to the ceiling as well as to the walls, always attach the ceiling panels first. By hanging the ceiling first, the panels can be cut a little short so that they slip easily into place. The wall panels, installed later, will fit against the ceiling to help support the edges.

Hanging a ceiling—at least without a mechanical panel lift—is a two-person job. And a third set of hands never hurts. I usually use adjustable step-up benches to hang ceilings that are 9 ft. high or less. I know a few drywall hangers who use stilts when attaching drywall. One crew member on the floor does the cutting and hands the panel to two other crew members on stilts. They in turn lift the panel into place on the ceiling and attach it, cut openings for any electrical boxes, and take the next measurement. Under ideal conditions, working on stilts is the fastest way to hang drywall on ceilings, but I don’t usually use them. The two members on stilts can’t cut and carry panels, which means a lot of work for the person on the floor. In addition, the work area must be kept clean and uncluttered to minimize the risk of falls.

Raising a PanelThough the first few boards can be awkward, two people can do efficient work hanging ceilings without a lift. Start with two step-up benches centered under the section to be hung, and be sure to carry fasteners on your belt. Get into position: Keep one end of the panel low while you position the other.

It’s a balancing act: Support the panel with gentle head pressure as you screw it in place. |

Prevent Sagging Ceilings

- Fur out the ceiling if on-center spacing is not adequate.

- Use a type of drywall more resistant to sagging.

- Control humidity in the structure before the work begins, while it is being done, and after the installation is complete.

- Prime before texturing. And always let the primer dry thoroughly before texturing.

- Hang the drywall perpendicular to framing.

- Avoid attaching drywall over sagging insulation.

My favorite way to hang high ceilings, especially cathedral ceilings up to 15 ft. high, is to use a mechanical panel lift. This tool does the heavy lifting while I position the panel. And once I’ve aligned the panel, the lift holds it in place while I attach it. It makes your work a little easier, and lifts can be rented from many drywall suppliers and home centers.

WORK SMART: If you’re hanging a cathedral ceiling without a lift, it’s easier to attach the lower panel first and then work your way up to the top. By starting at the bottom, you’ll have an edge for the next panel to rest on while you hang it. This is easier than trying to lift a panel up to fit against the bottom edge of the panel below it. By starting at the bottom, you’ll have an edge for the next panel to rest on while you hang it. This is easier than trying to lift a panel up to fit against the bottom edge of the panel below it. |

Ceiling panels can be hung perpendicular to the joists or parallel to the joists. I prefer to attach the ceiling panels perpendicular to the joists for a number of reasons:

- Ceiling panels are less likely to sag when hung in this direction (see the sidebar “Grain Orientation in Drywall”).

- It allows the butted seams to be attached to a solid nailer for the length of the seam or floated between the joists.

- It is easier to see the joists when fastening the panels.

- It gives the structure greater strength.

- It won’t matter that much (and may not even be noticed) if the on-center spacing of a ceiling joist is off.

- It allows the drywall to float over slightly uneven joists, making them less conspicuous.

Grain Orientation in DrywallArden Van Norman performed a simple test to prove that drywall is stronger with the grain than across it. A simple test proves that drywall is stronger with the grain than across it. |

The only time I hang drywall parallel to the joists is when doing so avoids creating butted seams on the ceiling, or when the method of application affects the fire rating or structural design. Before opting for this method, though, check the spacing of the joists carefully—they must be spaced so that the edge of each panel falls on the center of a joist. If the tapered edges don’t hit on center, you may have to cut the long edge of the panel, which will create a long butted seam. And take care not to create a seam on a joist that is either crowned up or sagged down, as it will be difficult to hide when taping. Also check to make sure the type of drywall you are using is approved for hanging parallel to the joist with the on-center spacing.

And take care not to create a seam on a joist that is either crowned up or sagged down, as it will be difficult to hide when taping. Also check to make sure the type of drywall you are using is approved for hanging parallel to the joist with the on-center spacing.

No matter the direction in which the panels are hung, if you cannot avoid butted seams, stagger them and keep them as far away as possible from the center of the ceiling. Discontinuous butted seams are easier to conceal and less likely to crack.

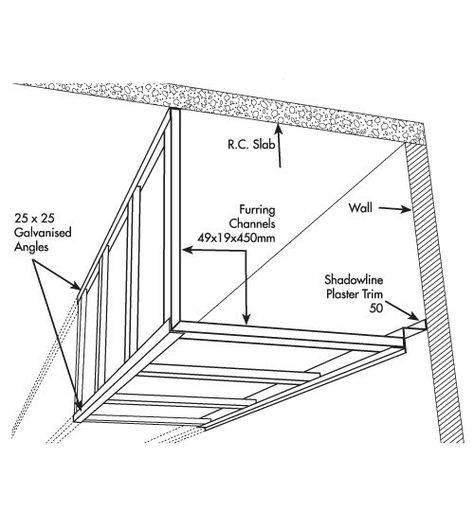

Before hanging drywall, some ceilings are first furred with 1×3s perpendicular to the joists. A ceiling may be furred for a number of reasons: to help straighten out a wavy ceiling, to decrease the distance between the nailers (ceiling joists), or to provide solid nailing over rigid insulation. The 2-1/2-in.-wide strips make an excellent target when fastening the drywall. The strips should be treated just like ceiling joists, and the drywall should be hung following the same procedures.

Previous: Why You Should Use Screws Instead of Nails for Drywall Next: Hanging Drywall Overhead

Guide

Drywall

Chapter

Hanging Drywall

Drywall

Drywall

Trusted, comprehensive guidance for choosing, hanging, taping, sanding, and repairing drywall—the right way

View Project Guide

View All Project Guides »

Become a member and get unlimited site access, including the Drywall Project Guide.

Start Free Trial

Drywall Basics

- Types and Uses of Drywall

- Planning the Job

Tools and Materials

Hanging Drywall

Taping and Sanding

Special Installations

Drywall Repairs

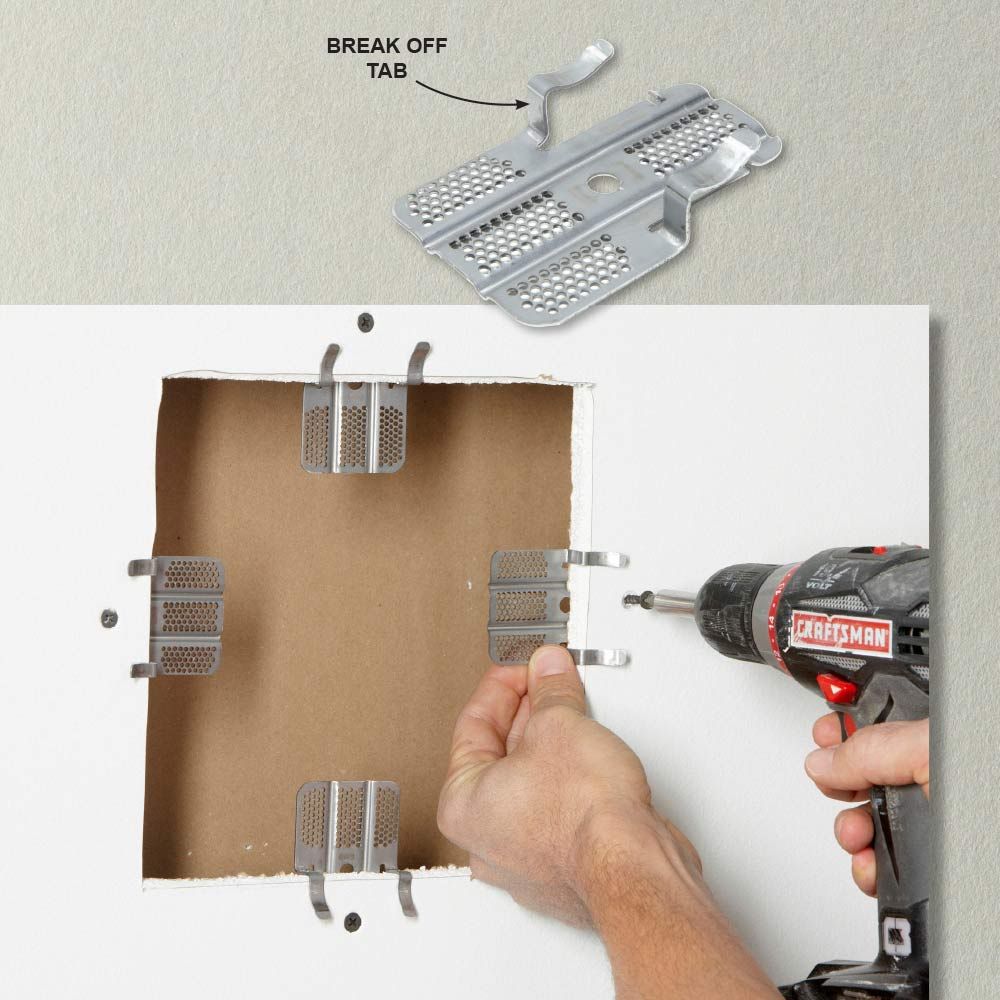

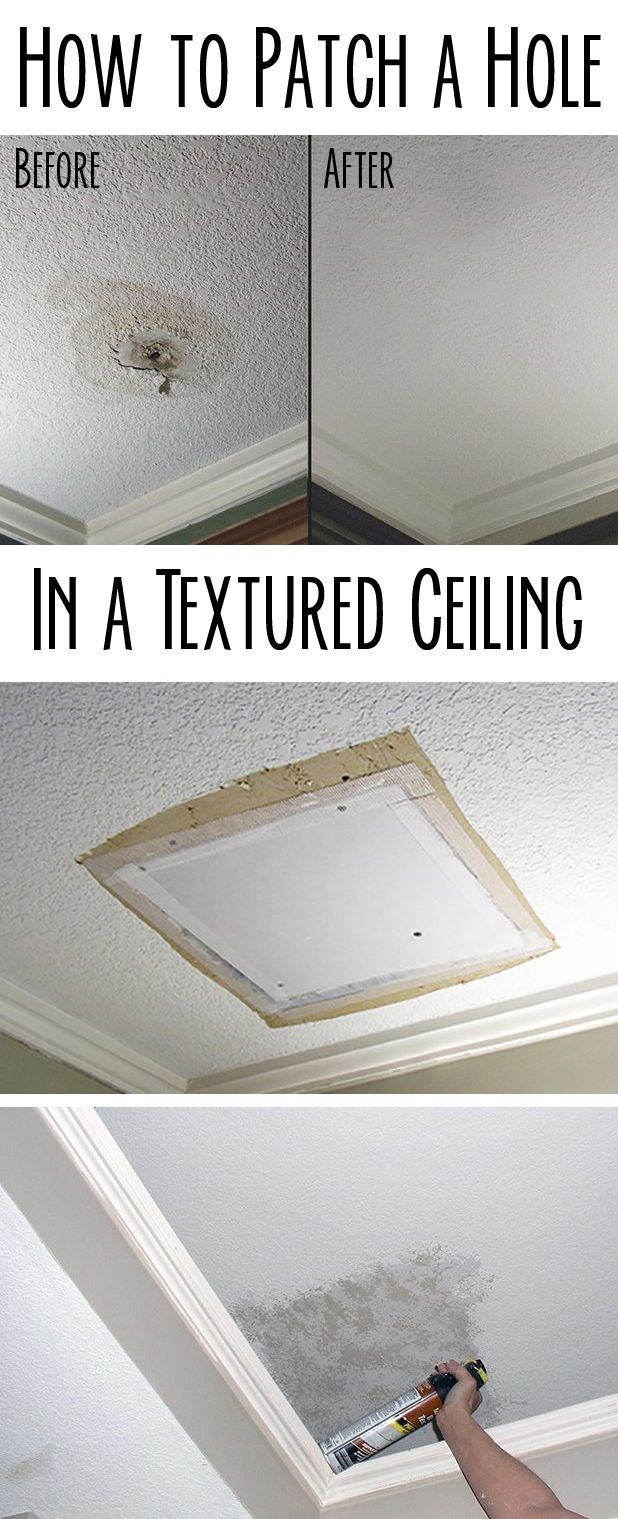

- Patching Holes, Cracks, and More

Plaster

expert tips for a sleek finish |

Drywall is a popular and versatile construction material, and learning how to hang drywall ceiling is handy DIY know-how to have up your decorating sleeve.

Commonly used to create walls and ceilings, it is often part of the core structure of a building, but can also be used to create architectural features like eaves and arches. Usually made of gypsum plaster, it's also commonly known as plasterboard.

While it may not be the most exciting project on your interior decor DIY list, it’s an important step and will certainly leave you feeling rather accomplished afterwards.

So, whether you're hanging a drywall ceiling instead of trying to remove a popcorn ceiling, or because your original ceiling is too damaged, these expert steps will help you get it right first time.

How to hang drywall ceiling

To make the most of your ceiling ideas, you may need to know how to hang drywall ceiling. You can then plaster a ceiling and consider texturing a ceiling or installing ceiling tiles.

Before you begin pay attention to any issues and fix ceiling leaks and deal with a ceiling with water damage.

Sometimes, it’s enough to patch a drywall ceiling but if instead you need to hang drywall ceiling, follow this step-by-step guide with advice from Nick Cryer, founder of high-end construction company Berkeley Place .

You will need:

- Drywall sheets

- Drywall screws

- Drywall adhesive

- Safety gloves and glasses

- Electric or battery screwdriver

- Utility knife

- Measuring tape

- Framing square

- T-square

- Drywall paper

- Putty

- Sandpaper

1. Ceiling before walls

'If you are drywalling the ceiling, fix the ceiling drywall first, then the walls,' advises Nick.

If you start drywalling the walls first, you could end up with the ceiling drywall being unsupported along the entire length of one wall. Wall panels installed later will fit against the ceiling to help support the edges.

2. Measure carefully

Measure the wall's width and cut the drywall sheet so that it's about 1/4in shorter than the measurement.

You can mark the exact dimensions on the plasterboard using your T-square and pencil. You can then use a utility knife to go over the line, before bending the board and cut as you go.

3. Ensure accurate placement

Remember that you have to install the drywall perpendicular to the direction of the joists.

'Before applying the drywall, ensure that the initial board will end up in the middle of a stud, the vertical framing component of a wall,' says Nick.

4. Use drywall adhesive and screws to fix

With an assistant, prop the drywall up and position it tight against the ceiling; it's best to start from a corner.

Score the mark with a utility knife and a drywall square, and snap the excess material against the line.

‘Place the board against the studs to have one edge fit snugly next to the ceiling board and another against the adjacent wall,’ says Nick. ‘Drive drywall screws into the center of the board at a convenient height. Once you've installed the first screws, put in the rest, working from the center of the board outwards.'

Make sure the boards are as close as possible to the walls; all edges of drywall should be fastened to the ceiling studs.

Two drywall boards should be connected on the same stud, before fixing screws with your electric screwdriver along the middle.

As you install your newly trimmed drywall boards, take some drywall adhesive and run it across the studs so that you won't need as many screws.

'Drywall adhesive will also enhance the noise reduction of your walls,' says Nick.

5. Apply putty and drywall paper

For a professional-worthy finish, it's a good idea to finish the joint with putty and drywall paper. Cover the screws ad drywall board joints with a trowel, paper tape and drywall putty.

After applying the putty, sand it with medium grit paper.

Can I hang drywall ceilings by myself?

It is possible to hang drywall ceilings, but it is easier and safer to have an assistant.

How much gap should be between sheets of drywall?

You should ideally leave about 1/4in gaps between sheets of drywall.

Is it best to hang drywall vertically or horizontally?

It’s better to hang drywall horizontally to reduce the amount of adhesive you use.

How to make a plasterboard ceiling with your own hands

November 16, 2019 Likbez Do it yourself

With Artyom Kozoriz's step-by-step guide, the process will take only a day and will not be more difficult than assembling a constructor.

1. Prepare materials

- Drywall 12.5 mm;

- profiles PP 60×27;

- profiles PN 28×27;

- profile extensions;

- single level connectors;

- straight hangers;

- screws 3.5×9 mm;

- screws 3.5×25 mm;

- dowel-nails 6×40 mm;

- anchor wedge 6×40 mm;

- reinforcing tape;

- primer;

- putty;

- hydraulic level or laser level;

- bubble level;

- batting cord;

- metal shears;

- screwdriver;

- perforator;

- drywall knife;

- planer;

- brush;

- putty knife.

2. Calculate the position of the false ceiling

Stone Boys YouTube channel The first step is to determine at what level the ceiling will be located. To do this, you need to find the lowest overlap point, add the thickness of the frame to it.

To do this, you need to find the lowest overlap point, add the thickness of the frame to it.

Using a hydraulic level, make a mark in one of the corners at an arbitrary height, and then transfer it one by one to the others. If you have a laser level, simply turn it on and mark the horizon at each corner.

Connect all the risks in one line along the perimeter of the room using a batting cord. Measure the distance from the reference line to the ceiling at the corners and several places along each of the walls. The smallest distance will show the lowest point.

If there is no need to specifically lower the ceiling, then mark down from the found point 40 mm: 30 for the thickness of the frame and another 10 for the gap for installation. When installing large recessed fixtures, add the height that they will protrude from the frame.

In our example, the lowest point is 1640 mm. We descend from it by 40 mm and get the ceiling level at a distance of 1,600 mm from the reference line.

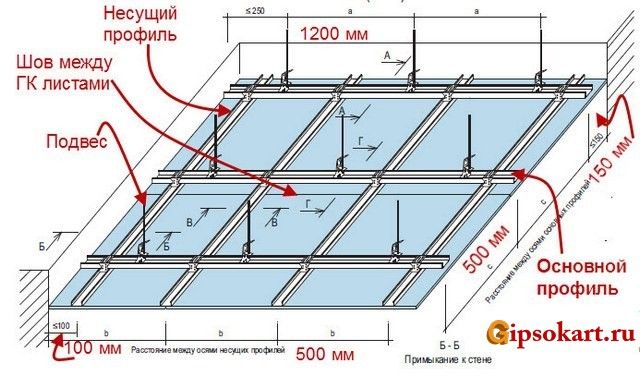

3. Mark out the frame

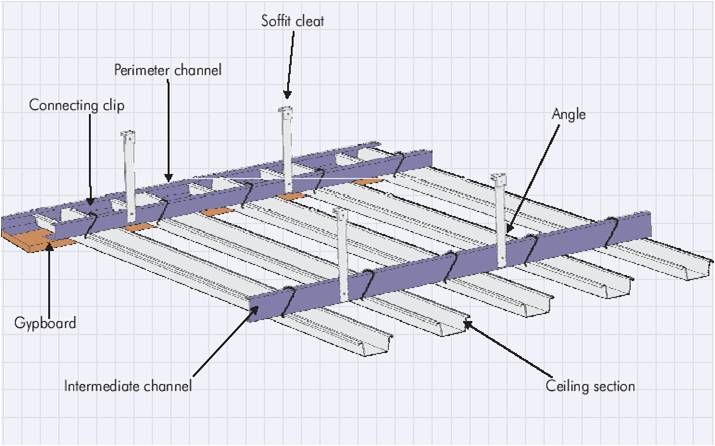

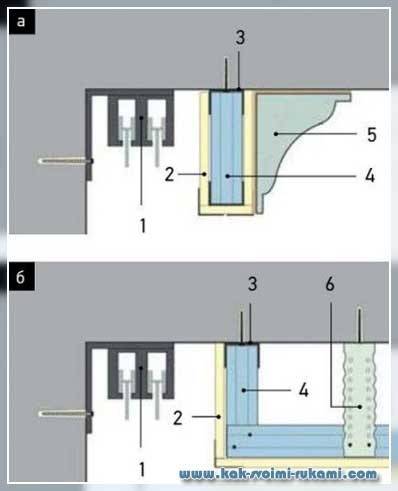

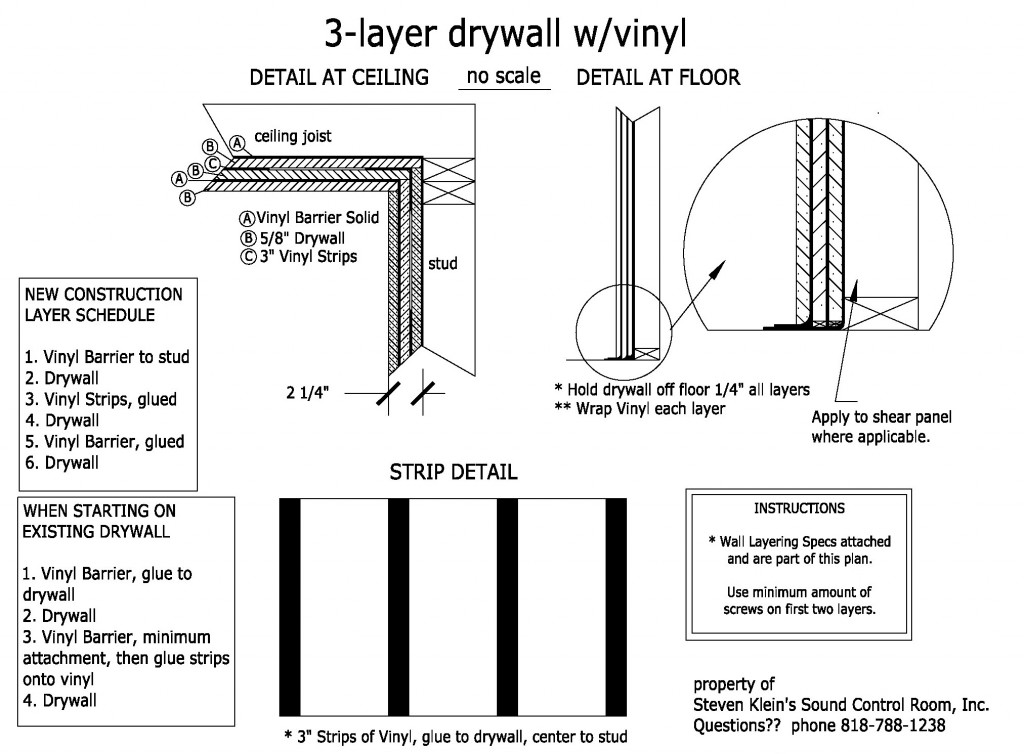

Stone Boys YouTube channelFor correct installation, you need to accurately mark the position of all frame elements. It consists of rails mounted on the walls, where the main profiles are installed, and those, in turn, are attached to the ceiling with suspensions. Supporting profiles are mounted across the main ones, onto which drywall is directly screwed.

- Guide profiles. We have already noted their position in the previous step.

- The main profiles are installed at intervals of 1200 mm along the axes. In this case, the beams extreme from the walls are located at a distance of ≤ 1170 mm.

- Suspensions are mounted in increments of 650–1000 mm.

- Support profiles are installed every 500 mm.

For example, let's mark a room 3.5 by 3.6 m. Three whole sheets clearly cover the entire width of the room. 1 m is missing in length, so we will add pieces of 1 × 1.2 m to each row. According to the installation technology, the joints of adjacent sheets should go apart, in the manner of brickwork. So, we start the first row with a whole sheet, the second - with a piece, and the third - again with a whole.

1 m is missing in length, so we will add pieces of 1 × 1.2 m to each row. According to the installation technology, the joints of adjacent sheets should go apart, in the manner of brickwork. So, we start the first row with a whole sheet, the second - with a piece, and the third - again with a whole.

Measure all required gaps with a tape measure. Put marks in the right places, and then connect them in a line with a chopping cord. Distribute the hanger mounts so that there is no more than 1 m between them, and preferably less.

4. Mount the guide profiles

YouTube channel "Knauf Russia" Fasten the profiles PN 28×27 along the perimeter of the room so that their lower part coincides with the previously marked line. If the wall is concrete or brick, attach the profile and mark the fixing points with a pencil. Then drill a hole with a puncher, insert a dowel through the profile and hammer the nail inside with a hammer. Guides can be fastened to wooden walls with self-tapping screws using a screwdriver without pre-drilling.

If necessary, butt the profiles without overlapping each other. Mounting pitch - 250-500 mm, but not less than three pieces per piece of profile.

For noise insulation, a special sealing tape or silicone sealant can be applied to the profiles before installation.

5. Fasten hangers

YouTube channel “Knauf Russia”Next, install hangers for the main frame profiles at the previously marked points. In reinforced concrete floors - with the help of metal wedge anchors and a perforator, in wooden ones - with self-tapping screws and a screwdriver. After installation, bend the hangers down.

They can also be sealed with sealing tape or coated with silicone for noise reduction. An even greater effect is achieved when using special anti-vibration suspensions with elastic inserts.

6. Install the main frame profiles

YouTube channel "Knauf Russia" Cut out the necessary pieces from the PP 60×27 profile and insert into the guides. Position them so that the centers of the beams coincide with the marks made earlier.

If the length of one profile is not enough, add an additional segment and join them together using a special connector.

7. Fix the main profiles in the same plane

Stone Boys YouTube channelTo get a perfectly flat plane for plasterboard lining, you need to align all the beams in one line. The easiest way to do this is with a regular thread.

Raise all profiles 10–15 mm upwards and fix by inserting screws into the hanger holes. Stretch the thread across the profiles between the walls and secure with self-tapping screws on the rails flush with the latter.

Also, the correct installation of the profiles can be controlled with a bubble level / YouTube channel “Knauf Russia”mm - two on each side.

First fix the hangers in the middle of the beams to remove the sag. After that, the main profiles will almost clearly fall into place. It remains only to check the thread and tighten the screws into the hangers.

8.

Install the supporting profiles YouTube channel "Knauf Russia"

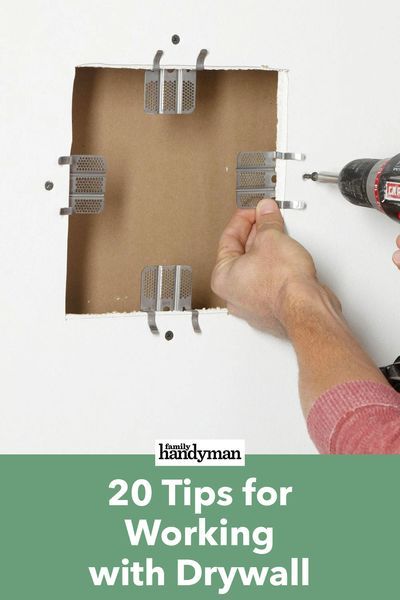

Install the supporting profiles YouTube channel "Knauf Russia" Now, across the main profiles, it is necessary to mount the supporting profiles that will hold the drywall. Cut the beams to size from the same PP profile 60 × 27 and fasten using single-level connectors (“crabs”).

If special fittings are not at hand, you can use PN profile trimmings about 100 mm long as improvised guides. They need to be attached to the main profiles with screws, and then the carriers should be inserted into them and also fixed with self-tapping screws.

9. Install the wiring and soundproofing

Electroas.comElectric cables must be laid before the plasterboard cladding. As a rule, they are attached to the ceiling or suspensions. In no case should you lay the wires inside the frame, since there is a risk of damaging them with screws when installing the sheets.

YouTube channel “Knauf Russia” To increase the sound insulation of the ceiling, mineral wool slabs are laid between the frame profiles or on top of it. With a sufficient length of the free ends of the suspensions, they are bent, thereby holding the sound insulation layer.

With a sufficient length of the free ends of the suspensions, they are bent, thereby holding the sound insulation layer.

10. Cut the sheets

YouTube channel “Knauf Russia”To cut the panels, mark the required size with a tape measure and, applying a profile or a rule, cut through the cardboard with a knife. Hang and break the cut off part, and then cut through the paper from the bottom side. Then trim the edge along the cut line with a planer.

Also, before installation, be sure to chamfer with a planer or knife at an angle of 22.5 ° on the edges that will adjoin other sheets. This is necessary in order to seal the joints with putty in the future.

Be sure to measure and mark on the sheets where the lighting wires are located. After the work is completed, the drywall can be easily cut through and the cables can be removed.

11. Line the frame with drywall

Knauf Russia YouTube channel Together with an assistant, lift the sheet and place it in its place. Fasten along the contour to all frame profiles. Join the sheets in one row only on the supporting profiles, not allowing the edges of the drywall to hang in the air. Mount plates in adjacent rows with an offset of at least one frame step.

Fasten along the contour to all frame profiles. Join the sheets in one row only on the supporting profiles, not allowing the edges of the drywall to hang in the air. Mount plates in adjacent rows with an offset of at least one frame step.

Screw the screws evenly, avoiding distortions. Do not leave their caps sticking out above the surface of the sheet, but do not sink too much: they should be flush with the drywall plane or 1 mm lower.

Fasten the screws in 150 mm increments, 10 mm from the papered edges and 15 mm from the open edges. Self-tapping screws on adjacent sheets are shifted relative to each other by 10 mm.

12. Seal the joints

YouTube channel "Knauf Russia"After installation, all joints of the sheets are covered with putty using reinforcing tape. To do this, first make sure that the screws are securely fastened and, if necessary, tighten the protruding heads with a screwdriver.

Then use a brush to dust off the seams and prime all cut edges. Fill the joints with putty using a spatula. Glue a reinforcing tape in the center of the joint and press it in with a spatula. Then apply a second layer of putty. With the same composition, seal the attachment points of all self-tapping screws.

Fill the joints with putty using a spatula. Glue a reinforcing tape in the center of the joint and press it in with a spatula. Then apply a second layer of putty. With the same composition, seal the attachment points of all self-tapping screws.

13. Finish the finish

Knauf Russia YouTube channelAfter sealing the seams, the tiled surface is ready for any kind of finishing: the ceiling can be painted, wallpapered or decorative putty applied.

Read also 🛠🛠🛠

- What you need to consider for arranging the perfect bathroom

- How to choose linoleum

- How to make self-leveling floors

- How to install an outlet

- How to install a bathtub yourself

DIY plasterboard ceiling

Recently, "dry" finishing methods have become more and more popular. The ceiling was no exception in this regard. Suspended ceiling is one of the common types of decoration. Consider how to make such a plasterboard ceiling.

Plasterboard false ceiling

Plasterboard ceiling is the most widespread. The main idea is that the ceiling frame is suspended on a “rough” base, then sheet material is attached to the frame, which creates a flat plane for any kind of fine finish.

The main idea is that the ceiling frame is suspended on a “rough” base, then sheet material is attached to the frame, which creates a flat plane for any kind of fine finish.

Do not think that a false ceiling can only be made of plasterboard. For these purposes, any sheet material is suitable: gypsum fiber sheet (GVL), aquapanels, wood composite materials (plywood, chipboard, OSB). But we will talk specifically about drywall, because this coating option is the most common.

Advantages and disadvantages of using drywall

Consider the main advantages and disadvantages of using drywall ceiling.

Advantages:

- The prevalence of the material - the popularity of drywall can be attributed to the advantages. GKL is not difficult to find in the right quantity, and a large number of craftsmen have experience working with this material.

- Do-it-yourself work - it is quite easy to work with drywall on your own.

Sheets are cut with a regular knife. For example, it will be difficult to make a stretch ceiling without many years of experience.

Sheets are cut with a regular knife. For example, it will be difficult to make a stretch ceiling without many years of experience. - Sustainability - drywall consists of a gypsum core and thick cardboard. These components do not have a negative effect on the human body.

- Ability to produce complex shapes - the material is well suited for the manufacture of complex multi-level false ceilings. GKL will allow you to create bends that cannot be done using other sheet materials (OSB, plywood, etc.)

- Relative strength - it is impossible to call a plasterboard coating durable, but compared to stretch ceilings, the material is more resistant to mechanical stress.

- High maintainability - patching holes in drywall is possible even without the involvement of a master.

- Fire resistance - material and all frame elements are classified as non-combustible materials.

- Concealed installation of communications - the material hides communications. True, the wiring is mounted in a hidden way, so in the future it will be more difficult to access it.

Disadvantages:

- Poor mechanical shock resistance - plasterboard on the ceiling can be easily pierced when rearranging furniture or cleaning.

Do not be surprised that the strength characteristic has got into pluses and minuses. This is a relative parameter and it depends on what material to compare with.

- Moisture Damage - Drywall will not protect against leaks from upper floors. Upon contact with moisture, gypsum swells and cracks - the suspended ceiling will need to be repaired.

- Long installation - construction work will take 2 - 4 days. At the same time, the installation of a false ceiling must be carried out at the stage of rough work.

During the work, a large amount of dust and debris is generated.

During the work, a large amount of dust and debris is generated. - Installation does not tolerate mistakes - this can be said about many materials, but this applies especially to drywall. Violation of technology leads to the appearance of cracks and the destruction of the finish. As a result, it will be necessary to eliminate errors and then restore the finishing layer.

Read the articles on the link "https://www.sdvor.com/articles/new/575/" about errors when mounting the frame and when fixing sheets.

Where to Install Plasterboard Ceilings

Before making your own plasterboard false ceiling, you should decide whether the room is suitable for installing such a structure. Here you need to immediately pay attention to three factors: humidity, room height and temperature.

- Gypsum is not afraid of negative temperatures, so it can be used in unheated rooms. Some types of suspended ceiling structures are deprived of this possibility.

- Humidity is drywall's weak point, it cannot be said that the material is not suitable for wet rooms. This is allowed, but subject to certain conditions. In most cases, other materials prove to be more resistant to ceilings in wet areas.

Drywall is often used under tiles to line walls in wet areas. In this case, the material is protected by a layer of tile adhesive, and the mills are not threatened by leaks from the upper floors. Read the article about laying tiles on drywall here.

- The height of the room must also be taken into account, since the suspended ceiling “takes away from the room” from 5 cm. A two-level ceiling can reduce the height of the room by 20 cm. m, and multi-level structures are best done in rooms of at least 3 m.

- Gypsum board varies in thickness, on the ceiling in most cases 12.5 mm is used. The rigidity of the entire structure depends on the thickness of the sheet.

The strength of the structure is given not by the frame, but by the plasterboard sheets that fasten this frame.

Drywall is divided into ordinary (GKL), moisture resistant (GKLV) and fire resistant (GKLO). Moisture resistant is suitable for wet areas, usually modified material with additional properties is more expensive.

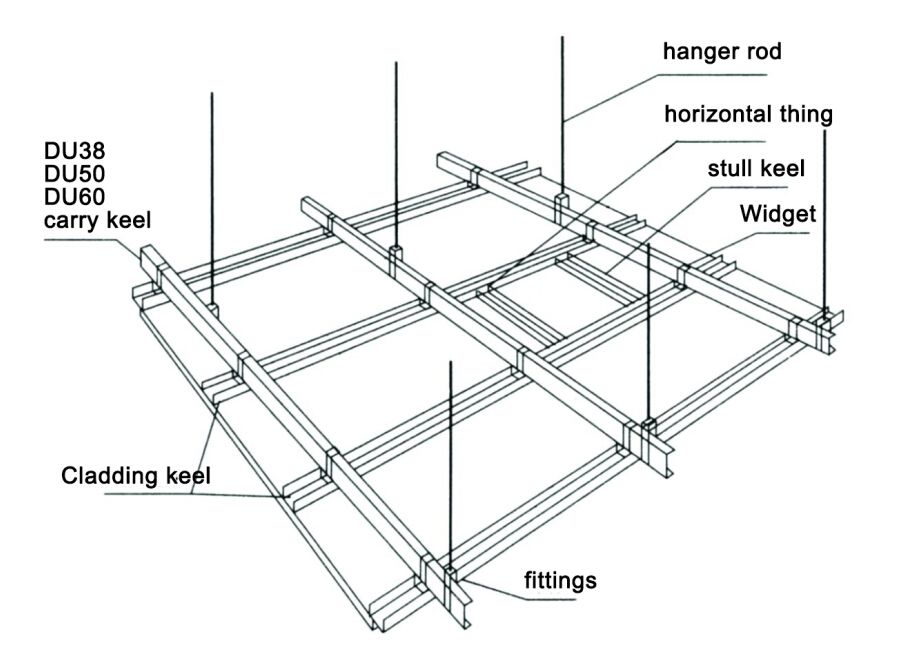

- galvanized profiles are required to form the frame. For suspended ceilings, two types of profiles are used: a ceiling guide (PPN, UD) and a ceiling profile for a crate (PP, CD). The profile differs depending on the thickness of the steel. The frame made of 0.3 mm steel bends easily in the hands, so it is better to use material with a thickness of 0.5 - 0.6 mm.

PPN

PP

The crate for the ceiling can also be made of wood, but it is more practical to install it on a galvanized profile, as it does not rot and allows you to get an empty space for communication between the plasterboard and the draft ceiling.

- hangers are required to secure the frame to the base. These elements are of two types: straight and anchor. A direct suspension ("crocodile") is made if the distance to the main ceiling does not exceed 12 - 12.5 cm. Such a suspension is one-piece, therefore, the thickness is adjusted when fixing the ceiling profiles.

Straight hanger

- Anchor hangers consist of a stud that is attached to the ceiling and a movable part with fastening under the profile. Anchor hangers can be lowered and raised after the profile is fixed on it, the distance between the drywall and the ceiling can be 12 cm.

0009 Sealing (damper) tape is used for soundproofing the room. It is glued to the back of the guide profiles. It reduces the spread of impact noise through the frame.

- Gypsum board varies in thickness, on the ceiling in most cases 12.5 mm is used. The rigidity of the entire structure depends on the thickness of the sheet.

In addition to the tape, you can create additional sound insulation on the fasteners. For this, there are special suspensions on a soundproof gasket.

For this, there are special suspensions on a soundproof gasket.

Impact sound emission with and without tape

- Fastener set includes dowel-nails for mounting rails, anchor wedges for fixing hangers to the ceiling base, black self-tapping screws for fastening profiles and for fixing drywall to the frame.

Tool kit for sealing GKL joints

- To seal joints , putty (in the form of a dry mix or ready-made) is required. Also, for joints, a sickle mesh or perforated sealing tape is required.

One-level crab connector

- Connectors are mandatory for ceiling installations, there are two types of connectors: one-level and two-level. When using a two-level ceiling thickness, it turns out more, therefore, with simple ceiling structures, in most cases a single-level connector (“crab”) is used. It allows you to create cruciform profile connections.

GKL profile extension

- Extension and needed to increase the length of the short profile. They are usually needed in large rooms that are not covered by standard profile sizes.

- Soundproofing and insulation - sometimes the creation of a suspended ceiling is combined with a soundproofing device and additional insulation, in which case heat-insulating and sound-proofing materials will be required. Usually this role is played by mineral wool.

Now consider the tools that will be required for the work.

- The Construction Knife is the most essential tool for drywall work. It is used for cutting material and for chamfering, if there is no edge planer.

- Edge planer required for chamfering cut edges. It allows you to cut the corner of the sheet at an angle of 22.5 degrees, so you can get 45 degrees at the junction.

Edge planer work.

Standard drywall sheet has a front and back side, on the front side of the sheet edges are chamfered (factory edges). Due to this, at the junction of two sheets, a recess is formed, which in the future is filled with putty. If during the installation of the GKL they cut, then the chamfers must be done independently. It is desirable to do this before fixing the sheets on the frame, but sometimes the craftsmen chamfer after mounting all the sheets. It is difficult for a beginner to make a neat cut. Read more about cutting drywall in the article "https://www.sdvor.com/articles/new/578" on our website.

Cutter is a tool for fastening profiles, it partially replaces self-tapping screws. When using a cutter, it must be remembered that there are many hard-to-reach areas on the ceiling where the tool cannot crawl through. The cutter makes holes in the metal and bends the edges. This keeps the elements together. At the same time, the head of the self-tapping screw does not rise above the surface.

At the same time, the head of the self-tapping screw does not rise above the surface.

Self-tapping screws with a press washer in some places can prevent drywall from adhering to the frame, in places where rigid fixation is required, they cannot be dispensed with.

- Metal shears may be required for cutting ceiling and track profiles.

- Drill or rotary hammer - required for drilling holes. For example, under dowels.

- Screwdriver is necessary for tightening a large number of self-tapping screws, you can not rely on a screwdriver, as your hand will get tired very quickly.

- Measuring devices - a bubble level is mandatory, it will be useful to have a laser level in the absence of a laser level, you can make a hydraulic level yourself. Also, if there is no laser level, it is useful to have lacing with paint for beating horizontal lines.

The hydraulic level operates on the basis of the law of connected vessels. Two containers with scales are connected by a flexible tube. Two people are required to use the hydraulic level.

Two containers with scales are connected by a flexible tube. Two people are required to use the hydraulic level.

Plasterboard ceiling installation instructions instructions

Stage 1. Marking the frame level and fastening the guide profiles

Before installing the profile, the ceiling must be thoroughly cleaned of dust and debris. It is also recommended to treat the surface with an antiseptic, especially this recommendation is important for wet rooms.

It is better to start with the markings when making a plasterboard ceiling. Using a bubble level, you need to find the most protruding part of the ceiling. From it down the wall we make a mark. This will be the thickness of the false ceiling. At this stage, you need to resolve the issue with built-in lighting. If it is, then immediately lay the size of the lamps in the thickness of the ceiling (from 9 cm). If there are no built-in lamps, then we make a mark at a distance of 5 cm.

At this level, we beat off the horizontal along the perimeter of the entire room. The easiest way to do this is with a laser level. If there is no laser level, then you need to make a hydraulic level. With it, we mark the corners, then with the help of a chop thread we draw a horizontal line.

We will fix the guide ceiling profile along this line. The bottom of the profile should go along the line. Fasteners should be in 50 cm increments or in 25 cm increments on loose substrates. There are already holes in the profile, but they do not always coincide with the points we need, so we make new holes if necessary.

If the wall to which the guide profile is to be attached is uneven, cuts must be made on the side planes of the profile. If this is not done, then the guide pressed by the fasteners will bend.

Glue the sealing tape on the reverse side of the guide profile. The minimum number of fasteners on one profile is three. For installation, you can use dowel-nails or nylon dowels with self-tapping screws with a press washer.

Step 2 Marking the ceiling profiles

The ceiling profiles should form the battens to which the drywall will be attached. It is first recommended to lay out the layout of the sheets on paper. The joints of the sheets should fall on the ceiling profile, the edges of the sheets should not be allowed to sag. Also make sure that no cross-shaped joints appear, for this the sheets should go apart.

Layout example

Sometimes the factory edge at the edge sheet is cut off to make it easier to putty. In this case, the distance from the wall to the first profile must take into account the dimension after cutting

The pitch between the ceiling profiles is 1200 mm, which corresponds to the width of the plasterboard sheet. This profile performs the main bearing function. Another ceiling profile is attached perpendicular to it (it is usually called "bearing"). With one side, the carrier profile is inserted into the guide, the other side is connected with a single-level connector to a perpendicular ceiling profile. They are recommended to be placed every 50 cm.

They are recommended to be placed every 50 cm.

Before starting work, mark the location of all profiles on the ceiling using a lacing tape.

Stage 3 Fixing the hangers

We already have the location of the ceiling profiles, now we need to install the hangers. They should be fixed on 2 anchor wedges. The quantity depends on the weight of the ceiling. The recommended distance between hangers is 1 meter if the weight of the ceiling is 15 kg per square meter. We make an indent from the wall 25 - 100 cm.

Step 4 Fastening the main profiles of the frame

We proceed to the fastening of the main profile, which comes in 120 cm increments. The length of the profile should be 10 mm less than the length of the room. The frame should not be rigidly fixed on the walls so that thermal deformations can occur freely.

It is convenient to use a magnetic level to level the frame, in this case you can magnetize the measuring device to the profile and not hold it with your hand. At this time, you can adjust the position of the frame we need.

At this time, you can adjust the position of the frame we need.

If the room is longer than the profile, the length must be increased by connecting several profiles. To do this, we use an extension cord. Direct suspension should cover the profile on both sides. Self-tapping screws are screwed into it from both sides. The height should be set according to the laser level or string should be pulled in the room. The evenness of the fastening should be checked using the rule and the level.

Direct hangers are more difficult to adjust than anchor hangers, since after screwing in the screws, the height of the direct fixing cannot be changed.

Once all profiles are level, you can fold back the ends of the hangers so that they do not interfere with the drywall sheets.

Stage 5 Installation of "crabs" and bearing profiles. Mineral wool

Bearing profiles are placed perpendicular to the main ones. First, every 50 cm, one-level connectors (“crabs”) must be installed on the installed profile. Then we cut the ceiling profile to size so that it can fill the gaps between the "crabs" on the ceiling. It is better to make a distance from the wall 10 cm.

First, every 50 cm, one-level connectors (“crabs”) must be installed on the installed profile. Then we cut the ceiling profile to size so that it can fill the gaps between the "crabs" on the ceiling. It is better to make a distance from the wall 10 cm.

The easiest way to cut a profile is with metal shears. To do this, two side walls are cut off from the profile, then it is bent and the back surface is cut off. At the same time, it must be remembered that the length of the carrier profile must be less than the distance from one main profile to another, so there will be no expansion.

The supporting profile must be screwed to the crabs with self-tapping screws. Each profile is fixed with two hardware, in total, 8 self-tapping screws may be required for one fastening.

When the frame is formed, you can start laying the insulation. Mineral wool must be placed in the gaps between the racks of the frame.

Step 6. Sheathing the frame with plasterboard

The drywall sheets are fixed to the frame according to the layout that was previously marked on paper. Before installation, you need to make chamfers on the edges; for this, you can use an edge planer or a construction knife. You can also chamfer after fixing the sheets, but on the ceiling it will not be so easy to do. If there are protruding corners in the room, then sheets cannot be joined on them, it would be more correct to make a tie-in.

Before installation, you need to make chamfers on the edges; for this, you can use an edge planer or a construction knife. You can also chamfer after fixing the sheets, but on the ceiling it will not be so easy to do. If there are protruding corners in the room, then sheets cannot be joined on them, it would be more correct to make a tie-in.

Please note that the sheet should not rest close to the wall anywhere, there should be a temperature gap of 3 - 5 mm everywhere. Since the factory joint is not always justified when adjoining the wall, it sometimes makes sense to cut it off and chamfer it. This way you can reduce the consumption of putty

There are usually no factory chamfers on the ends of the sheets, so they will also need to be made. For cutting sheets, it is better to use an ordinary construction knife: first we cut through the top layer of cardboard, then the sheet is shifted to the edge of the plane and the gypsum core is broken. A break is made in the opposite direction from the cut, after which the cardboard is cut from the reverse side. Roughness on the edge can be removed with a planer.

Roughness on the edge can be removed with a planer.

Two people are required to lift sheets to the ceiling. If the work is performed by one person, then a lift will be required that will hold the sheet at the desired height.

Drywall is fixed to the frame with self-tapping screws, the step between them should be no more than 15 cm. The hat should be slightly recessed by 1 mm, while it should not tear the cardboard itself. If you overdid it and screwed the screw too deep, then you need to unscrew it, seal the hole with putty, and make a new mount in another place.

Also make sure that the screw is not too close to the edge of the sheet. The distance to the edge should be at least 5 - 10 mm, but not more, because then you run the risk of simply missing the profile.

Stage 7. Sealing of joints GKL

When all the main work on the installation of plasterboard false ceiling in the apartment is completed, you can proceed to sealing the joints. This will require a sickle tape or perforated tape, putty, several spatulas, containers, a primer and brushes.

This will require a sickle tape or perforated tape, putty, several spatulas, containers, a primer and brushes.

First, it is important to properly prime the joints. For these works, it is necessary to take a deep penetration soil with a large proportion of dry residue. It is better to apply the primer with a brush, and not with a roller, since the brush allows you to well coat the joints and chamfers. After processing, the time must pass, which is indicated on the instructions for the primer composition.

If we use dry filler, it must first be kneaded. To do this, it is better to use a small container, it is necessary to prepare the solution in small portions so that the mixture does not have time to harden.

To mix putty, you need to use a clean container and clean tools, the remnants of old solutions will get into the fresh mix and disrupt the uniformity of the structure.

Pour water into the container, then start pouring dry putty in small portions. We do this until dry elevations remain on the surface, after that we mix the composition with a spatula, leave it for 10 - 15 minutes. Then mix again until smooth and you can work.

We do this until dry elevations remain on the surface, after that we mix the composition with a spatula, leave it for 10 - 15 minutes. Then mix again until smooth and you can work.

First you need to fill the joint with mortar with a small spatula, then apply another layer of putty. A perforated tape or mesh is glued onto it. The tape can be pre-soaked in water. With a spatula, the tape must be well glued to the surface of the seam, then the tapes are covered with another layer of mortar.

Instead of joints, it is necessary to cover with putty and self-tapping screws that fastened the drywall to the frame. Detailed instructions for sealing drywall joints can be found at "https://www.sdvor.com/articles/new/573/".

When the putty has dried, its surface must be sanded. The skin can be wound on a bar or fixed on a special grater, if any.

Additional work

In some cases, when installing a plasterboard false ceiling, additional measures may be required.

Cutting holes for luminaires

The need for recessed luminaires should be considered at the stage of planning the ceiling. Firstly, the space inside the ceiling should be enough to accommodate appliances. If the room has low ceilings, then taking an additional 5 cm under the equipment will not be a good idea.

Luminaires must also be taken into account immediately on the plan and before the installation of the frame. It is necessary to make a communication line for all lamps. The electrics in the plasterboard suspended ceiling are mounted in a hidden way, so the requirements of the PUE for this type of installation must be observed.

When the basic steps of the ceiling installation are completed, you can proceed to drilling the holes for the lights. This will require a core drill that can make round holes. The scheme drawn up earlier will avoid falling into the frame profiles.

Painting the ceiling with water-based paint

At the final stage, you can paint the plasterboard ceiling with water-based paint. The surface must first be primed. The easiest way to apply paint is with a long-handled roller. Excess coloring composition can be removed with a cuvette. Hard-to-reach places and the ceiling next to the walls are easier to brush.

The surface must first be primed. The easiest way to apply paint is with a long-handled roller. Excess coloring composition can be removed with a cuvette. Hard-to-reach places and the ceiling next to the walls are easier to brush.

How to make the backlight

The location of the backlight is also decided at the design stage. This question is more related to the design project. It is desirable that the backlight not only performs a decorative function, but also plays the role of additional lighting.

- Perimeter lighting creates a bright outline of the ceiling. If the ceiling has several levels, then both are illuminated. This type of illumination is created using LED strips, which are glued in special recesses.

- Spotlights - can also act as the main source of light, but they do not cope with this function as well as a chandelier. Under them, in drywall, you need to make round holes, to which you must first bring an electrician.

Alternatively, you can use a T-support to hold the panel in place.

Alternatively, you can use a T-support to hold the panel in place. He cut one 1-ft. by 4-ft. piece from the end of a panel and one from the side, as shown in the drawing. Stacking bricks in the middle of each piece quickly shows that the end piece is much weaker than the side one. Drywall is approximately three times stronger in the long direction. Accordingly, drywall hung perpendicular to the framing members is stronger than drywall hung parallel, so it is less likely to sag.

He cut one 1-ft. by 4-ft. piece from the end of a panel and one from the side, as shown in the drawing. Stacking bricks in the middle of each piece quickly shows that the end piece is much weaker than the side one. Drywall is approximately three times stronger in the long direction. Accordingly, drywall hung perpendicular to the framing members is stronger than drywall hung parallel, so it is less likely to sag.