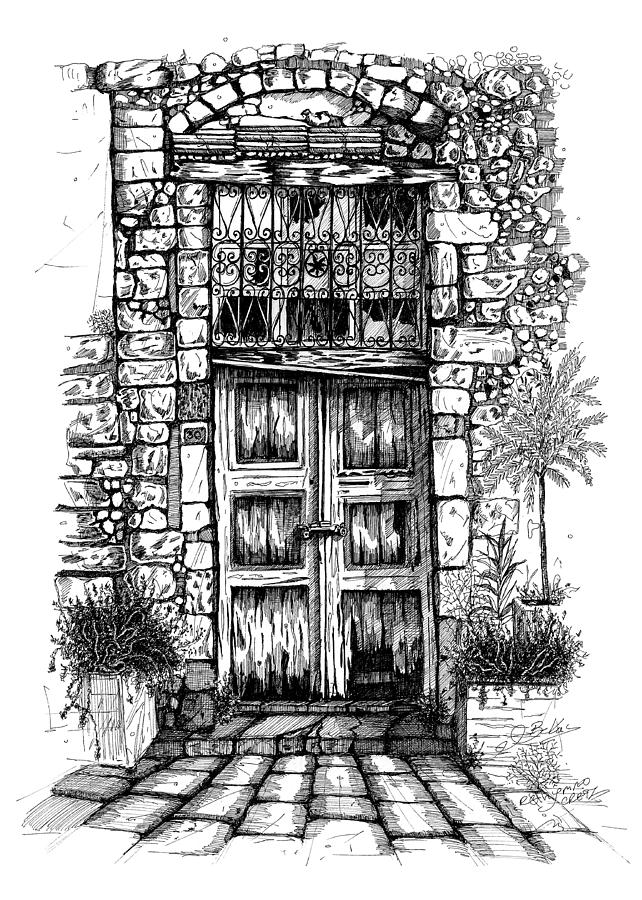

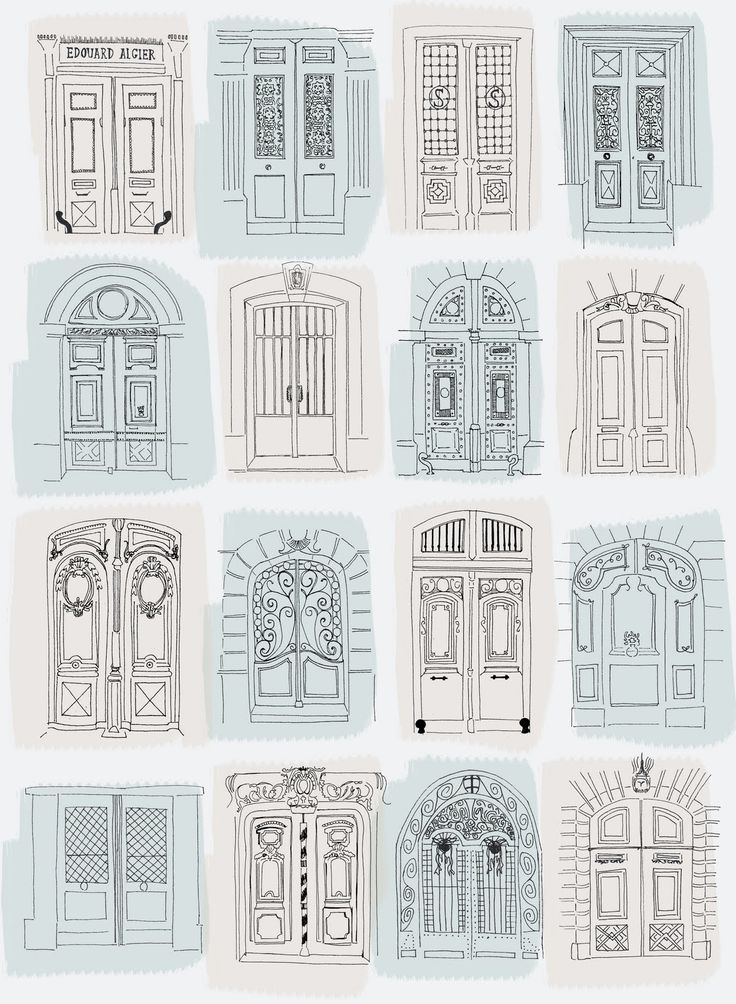

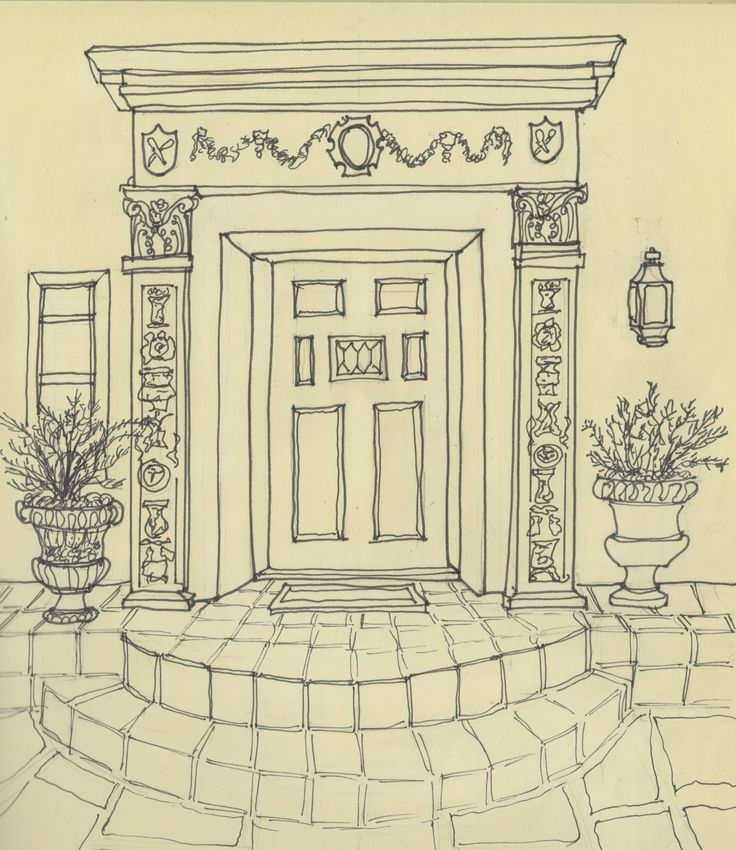

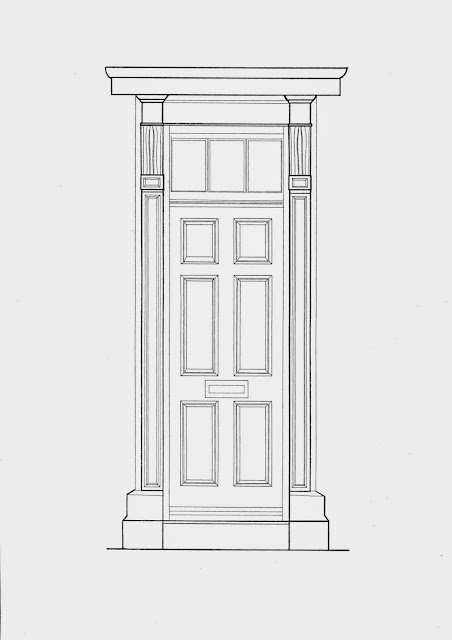

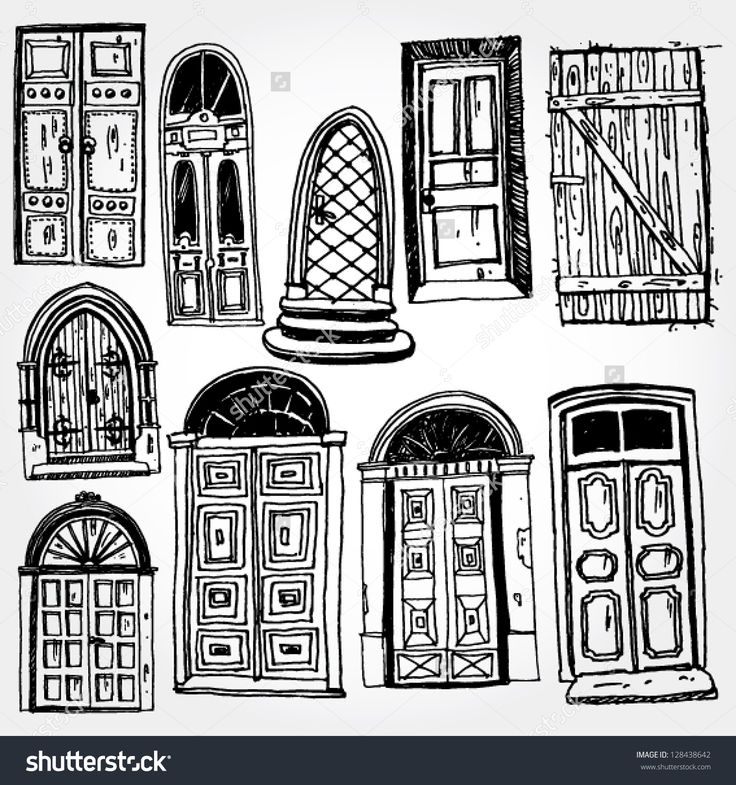

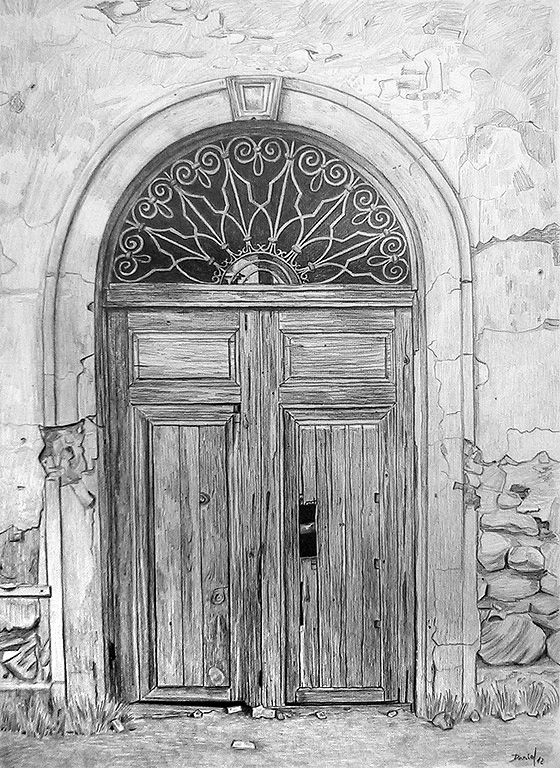

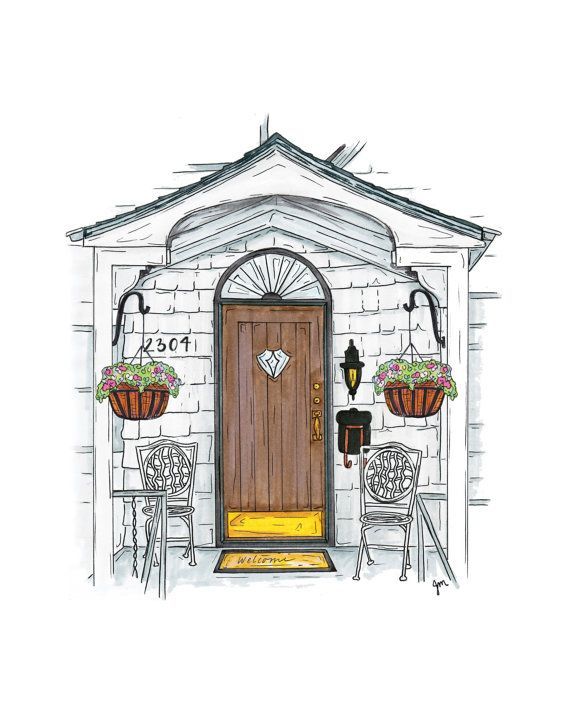

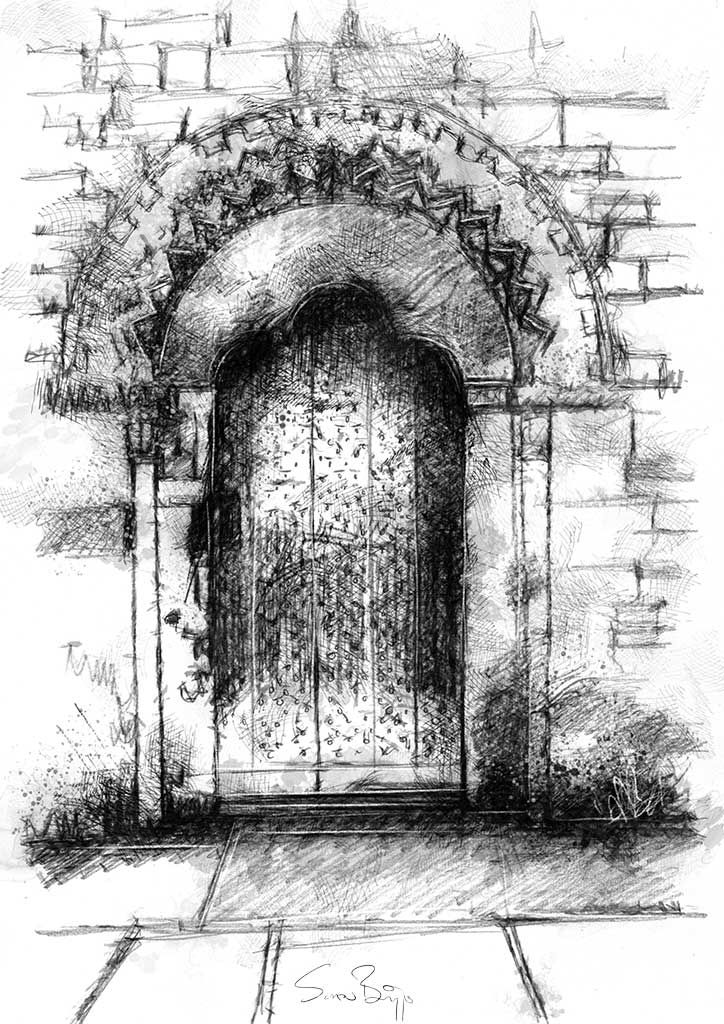

Front door drawings

50 Modern Front Door Designs

Like Architecture & Interior Design? Follow Us...

- Follow

Home Designing may earn commissions for purchases made through the links on our website. See our disclosure policy.

The front door is often the focal point of a home exterior – a door is the first thing guests see when they arrive, it's the last thing they contemplate after leaving, it's visited daily by the mail delivery, and it gives potential buyers something to remember the house by. An ordinary home can become "the house with the red door" with nothing more than a simple coat of paint, while a magnificent piece of architecture can rely on a unique door style to tie its exterior design together. Why settle with normal? This post looks at 50 spectacular front doors that boast expressively tailored personality and style.

- 1 |

- Architect: Stuart Silk Architects

- 2 |

- Architect: Sanders Pace Architecture

- 3 |

- Via: Sean Myers

- 4 |

- Architect: SBCH Architects

- 5 |

- Architect: ONG & ONG

Here, a matching walking path further differentiates the entryway from the paved parking and patio tiles.

Here, a matching walking path further differentiates the entryway from the paved parking and patio tiles. - 6 |

- Architect: McClennan Architects

- 7 |

- Architect: Atelier M+A

- 8 |

- Source: Daniel James Hatton

- 9 |

- Via: Martha Stewart

- 10 |

- Designer: Joseph Douglas

- 11 |

- Source: Bramco Builders

- 12 |

- Designer: Jute Home

- 13 |

- Architect: Sculp[IT]

Mechanized hardware allows designers to overlook the weight of the doors so the homeowners can go as big and bold as they want.

Mechanized hardware allows designers to overlook the weight of the doors so the homeowners can go as big and bold as they want. - 14 |

- Source: Borano

- 15 |

- Designer: Keratuer

- 16 |

- Designer: Axolotl

- 17 |

- Designer: Minarc

- 18 |

- Designer: Axolotl

- 19 |

- Designer: Axolotl

- 20 |

- Via: Casa Vogue

- 21 |

- Designer: Axolotl

- 22 |

- Designer: Axolotl

Its aluminum coating contributes substantial visual weight.

Its aluminum coating contributes substantial visual weight. - 23 |

- Designer: Denai Kulcsar Interiors

- 24 |

- Designer: Axolotl

- 25 |

- Designer: Michael Fullen Design Group

- 26 |

- Architect: Mahoney Architect & Interiors

- 27 |

- Architect: Silvas Studios Architecture

- 28 |

- Architect: MCK Architects

- 29 |

- Architect: Dick Clark Associates

- 30 |

- Designer: Mark Tessier

- 31 |

- Architect: Workroom

- 32 |

- Architect: Chamberlain Javens Architects

The golden ratio inspired sidelights reinforce the artistic elements at play here.

The golden ratio inspired sidelights reinforce the artistic elements at play here. - 33 |

- Designer: Jennifer Post

- 34 |

- Via: Minha Casa

- 35 |

- Designer: Denise McGaha Interiors

- 36 |

- Architect: Furman + Keil Architects

- 37 |

- Architect: Olson Kundig Architects

- 38 |

- Designer: Karim Rashid

- 39 |

- Designer: Karim Rashid

- 40 |

- Source: Inside Out

- 41 |

- Via: Skona hem

- 42 |

- Architect: Moises Esquenazi and Associates

- Photographer: Studio DIY

- 43 |

- Via: The Transcontinental Affair

- 44 |

- Architect: Matharoo Associates

- 45 |

- Via: Permahaus

- 46 |

- Photographer: Toni Kaarttinen

- 47 |

- Architect: Peter Zumthor and Gottfried Böhm

- 48 |

- Via: Livemaster

- 49 |

- Source: Decoesfera

- 50 |

- Via: Photobucket

A great door design can be made special with a few additional things. Explore these to truly take your entry to the next level:

40 Unique Door Knockers To Add Drama To Your Door

40 Decorative Door Stops That Leave The Door Open For Conversation

30 Funny Door Mats To Give Your Guests A Humorous Welcome

Front Door Drawing - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

Drawing of a metal door with dimensions, making a box and leaf with your own hands

Author Michael Reading 8 min Views 5. 3k. Posted on

3k. Posted on

Reliable metal doors are used virtually everywhere. They are installed not only in apartments of multi-storey buildings, but also in private households, baths, and various outbuildings. In addition to purchased ready-made options, some people prefer to create a home-made design, in which a drawing of a metal door will be a good help. nine0005

It is far from always possible to purchase a steel door leaf and a door block of proper quality. The first problem is the pricing policy of the modern construction market. The second problem is that sometimes the doorway is very specific and the doors for it are made only on an individual order.

There is a simple way out of this situation. If there are practically no suitable products on sale, you can always make them yourself. The metal door has a simple design, which is quite possible to make with your own hands. To do this, there are various drawings and much more. A home-made design will have the required level of quality, and the amount spent on materials will not be very high. All work on the manufacture of entrance doors is divided into several simple steps. nine0005

A home-made design will have the required level of quality, and the amount spent on materials will not be very high. All work on the manufacture of entrance doors is divided into several simple steps. nine0005

Content of Article

- The necessary materials, tool

- Preparation and measurement

- Production of a classic door of metal

- Assembly of the door frame

- Assembly of the door frame

- Production Insulation and finishing

- Metal door with glazing and decorative elements

- Homemade door compared to the factory one

Required materials, tools

The most expensive thing you need is metal. All other components and materials will not cost too much, of course, excluding decorative finishes. If you roughly estimate the amount for all expenses, then you need no more than 100-150 dollars. For this price, it is impossible to purchase even dubious Chinese products.

As for the materials needed for the job, they are few. You need to purchase a profile pipe - suitable with a cross section of 20 × 40 mm. The pipe should be purchased in the amount of 20 linear meters - this volume is quite enough for the production of a block of standard sizes (this is about 1 m wide and 2 m long). The amount of material for other dimensions is not difficult to calculate. In case of any incomprehensible situations, it is worth looking at the sketch - today you can find a lot of drawings of metal doors and use them for assembly. nine0005

You need to purchase a profile pipe - suitable with a cross section of 20 × 40 mm. The pipe should be purchased in the amount of 20 linear meters - this volume is quite enough for the production of a block of standard sizes (this is about 1 m wide and 2 m long). The amount of material for other dimensions is not difficult to calculate. In case of any incomprehensible situations, it is worth looking at the sketch - today you can find a lot of drawings of metal doors and use them for assembly. nine0005

Sheet metal is also required. Its thickness must be at least 2.5 mm. Overall dimensions - according to the size of the future door, or rather the opening.

You should also prepare hinges, it is worth choosing models that are equipped with a bearing. These accessories are purchased in quantities of three. The canvas will be quite heavy, so three loops is the most reliable option.

In addition, accessories, thermal insulation, as well as materials for decorative finishing are additionally needed. Do not forget about consumables - these are circles for power tools, welding electrodes, drills, consumables for a jigsaw. nine0005

Do not forget about consumables - these are circles for power tools, welding electrodes, drills, consumables for a jigsaw. nine0005

From the tools it is worth preparing a welding machine, a table for welding, a grinder, an electric drill, an electric jigsaw.

Preparation and measurements

So, the standard size of the doorway in most apartments is 2000x800 or 2000x900 mm. If the existing opening is smaller or larger, then you can make a canvas for a special size. When taking measurements, it is worth making sure that it is the wall that is being measured, and not concrete or plaster.

If the height of the box is slightly more than 2000 mm, then it is necessary to provide an additional frame on top, or in the side part of the opening, if its width is more than 900 mm. In addition, you should remember about a gap of several tens of millimeters on each side of the box. This gap is necessary for blowing seams.

If the width of the opening is more than 1500 mm, then experts recommend making not a solid (monolithic), but a collapsible box. In cottages, in addition to the door leaf, two or more modules with glass are installed in wide openings, which make the structure more reliable and durable and perform a decorative function.

In cottages, in addition to the door leaf, two or more modules with glass are installed in wide openings, which make the structure more reliable and durable and perform a decorative function.

Manufacture of a classic metal door

Classic steel doors are a structure made of leaf, frame, door hinges, and mounting plates.

Assembling the door frame

So, the first step is to assemble the frame or block. To do this, according to the parameters obtained during the measurements, a prepared profile pipe is cut. Cutting is performed at an angle of 45 degrees. Cutting accuracy can be checked by joining two pieces, and then checking the resulting structure with a corner.

There is another way to make a box. In this version, the frame is assembled from a metal profile by welding. The result should be a rectangular structure. During the assembly process, it is very important to control the accuracy of the corners, as well as measure the diagonals - this is done to eliminate the risk of block distortions. nine0005

Assembling the door frame

At this step, blanks for the future frame are made. For these purposes, a metal corner is suitable. It is necessary to maintain a gap between the door frame and the frame on the side of the lock - it is approximately 5 mm. On the other sides, it will be enough if the gap is 3 mm. These are not exact numbers - in various drawings of metal doors, this size may be slightly different. To make it clearer, strips of metal of the required thickness are used to measure and control these gaps. nine0005

Further - the profile is marked and cut. It is put inside the resulting box. Then check the geometric characteristics of the structure along the diagonals. If everything is correct, then a groove or slot is made on one side of the profile for mounting the lock. After that, the corners of the frame can be tacked by welding, the frames along the perimeter are also tacked at several points.

If everything is correct, then a groove or slot is made on one side of the profile for mounting the lock. After that, the corners of the frame can be tacked by welding, the frames along the perimeter are also tacked at several points.

At this step, it is already possible to weld metal strips to the door frame, which will act as clamps for finishing materials. nine0005

Making the door leaf

The creation of the door leaf should start with marking. It is necessary to take into account the tolerances and overlaps of sheet metal on the door frame of 10-15 cm. The overlap from the side of the hinges is also taken into account. In various drawings of metal doors, it is 5 mm.

Steel sheet according to the drawings and dimensions is cut with a grinder and welded to the finished frame. Stiffeners are welded inside the canvas. They must be installed horizontally. If the level of rigidity is insufficient, then their number can be increased. nine0005

nine0005

Fitting the lock

The door is almost finished. To install the lock, markup is performed directly on the canvas. You can mark the places for the holes with a regular marker. Then, according to the marks, a hole is drilled, which then needs to be processed with a file. Next - holes are made for the fasteners of the future lock. Threads are cut in the holes, then the locking device is fixed with bolts. At the end, install the handle.

This is a typical instruction that fits most locks, but lock designs may vary, installation depends on the product. nine0005

Hinges

Before welding these elements to the resulting structure - the doors and the block, they must be lubricated. With the help of a grinder, the places where the frame and the door block are connected are cut - these are the points that were previously tacked by the welding machine. Loops are fixed from the inside.

Fasteners

Metal strips are used to fasten the resulting structure into the opening. They need from 6 to 10 pieces. They are simply welded to the box. Then they will need to drill holes for the anchor bolts. nine0005

They need from 6 to 10 pieces. They are simply welded to the box. Then they will need to drill holes for the anchor bolts. nine0005

Insulation and finishing

The door is almost ready. Now it remains only to insulate it. The thermal insulation option you have chosen is cut and laid inside the canvas. Lay the insulation between the stiffeners.

Now you can start decorating the inside of the door. For these purposes, plywood, laminated panels, as well as any other material are suitable.

Metal door with glazing and decorative elements

Often, these door models are installed in private houses or cottages. The window performs several functions - through it you can see who came. Also, thanks to the glass in the hallway will be much lighter. Decorative elements will decorate the canvas and give it an exclusive look.

The window in the door has to be made even when the steel sheet is being cut. During its manufacture, you can draw a metal door, located at the beginning of our article. Reinforcement must be welded along the perimeter of a rectangular or any other shape of a hole in a steel sheet. Dimensions should be determined in advance. All other stages of work are similar to the manufacturing technology of a classic door. nine0005

Reinforcement must be welded along the perimeter of a rectangular or any other shape of a hole in a steel sheet. Dimensions should be determined in advance. All other stages of work are similar to the manufacturing technology of a classic door. nine0005

After the structure is painted, a double-glazed window is installed in the place intended for the window. In order for the glass to be as reliable as possible, a forged decorative grille is often welded on the outside.

You can also equip the door unit with various accessories. It can be closers, seals, eyes and much more. The main rule is that the accessories must be of high quality. Only then will it last for a long period of time. nine0005

Homemade door compared to the factory one

The first minus is the rationality of this solution. The cost of materials and accessories is a considerable amount, while the simplest factory door will cost 30% more, and you will save a lot of time and effort. In addition, your skills as a welder are important. If you are not qualified enough, there is a risk of marriage being allowed. In any case, factory welding will be much better.

In addition, your skills as a welder are important. If you are not qualified enough, there is a risk of marriage being allowed. In any case, factory welding will be much better.

But generally speaking, a homemade metal door is not a utopia, but a real reality for those who have welding skills and experience with power tools. nine0005

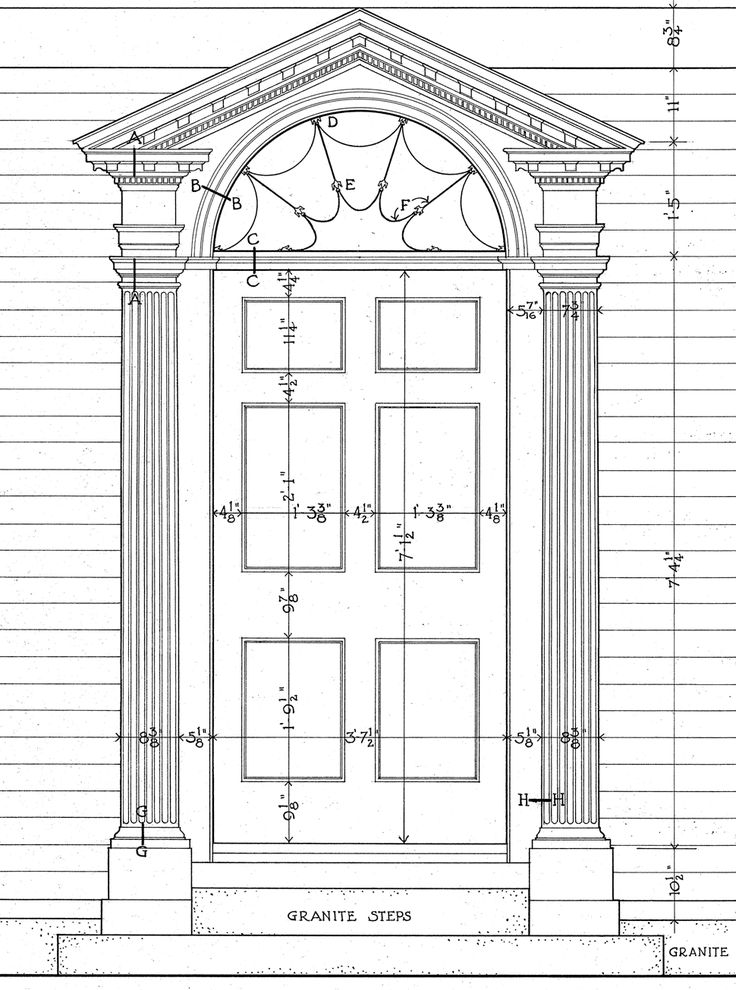

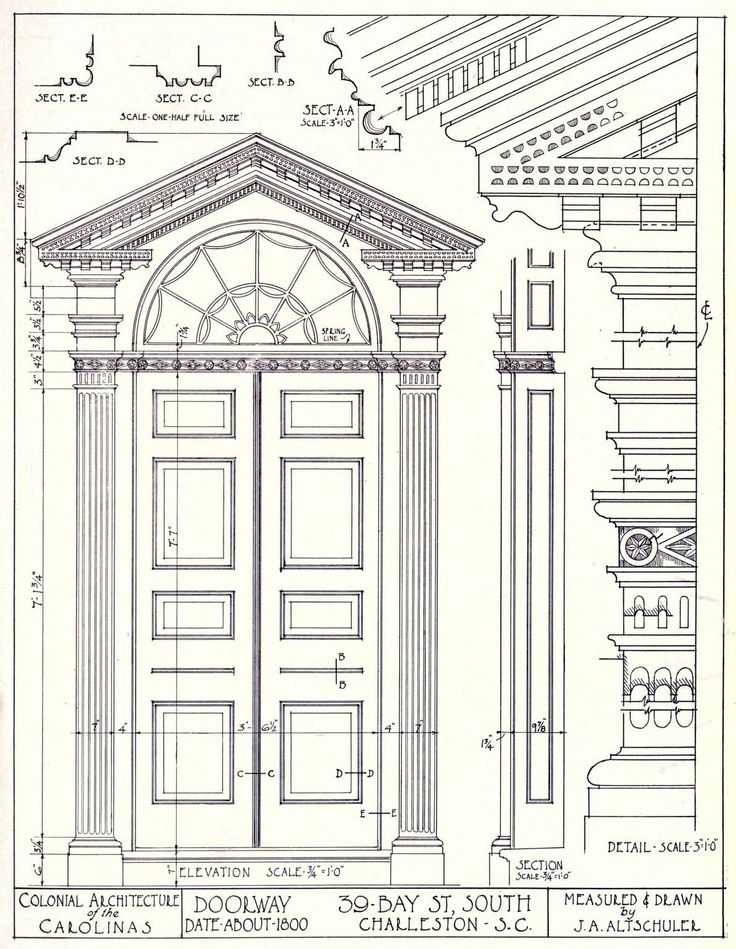

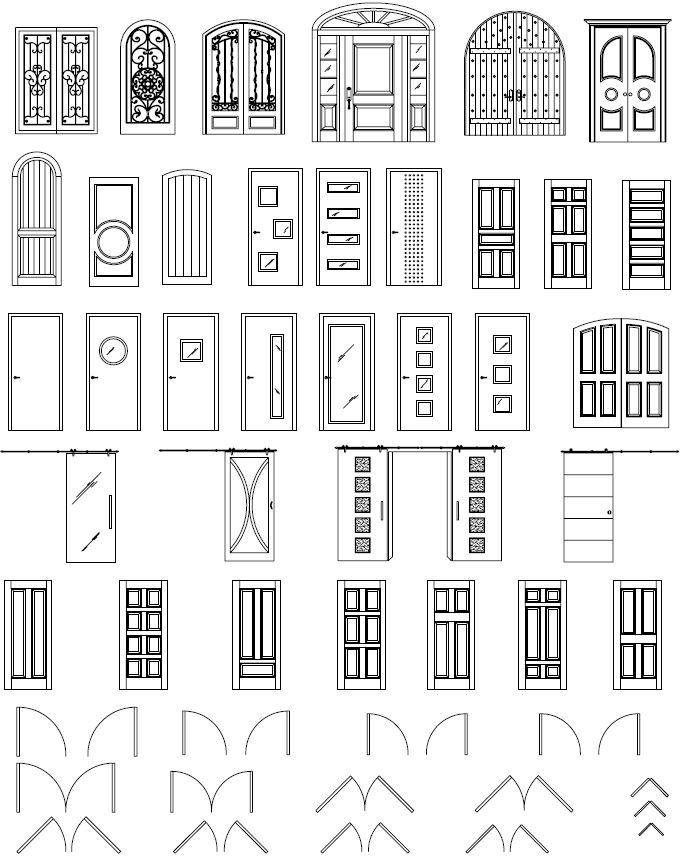

Drawing of a metal door with dimensions

Making a metal door with your own hands

Even a novice craftsman can do this if he knows how to handle a welding machine.

Of course, you won’t be able to make a complex model right away, but it’s quite affordable to make and install a basic model of an entrance door.

The importance of the front door is hard to underestimate.

This is not only the first and main barrier that prevents the penetration of dishonest citizens into your home, but also one of the key details of the interior of a residential building. nine0005

Noise insulation and room temperature control are two more functions of the entrance metal door.

And if you start a major overhaul in the apartment, then the question of installing a new entrance metal door is one of the first to be decided.

A finished door purchased in a store does not at all guarantee that it does not have hidden defects, and the prices there are not always affordable, its adjustment will be difficult, and sound insulation will certainly not suit you. nine0005

Well, you still have your own shaped doors, but we'll start with the simplest.

Preparatory work

As in other cases, the manufacture of a metal door begins with paper work, in other words, we have to create a drawing.

In order for the drawing to be accurate and true to reality, you have to decide on the dimensions.

The design scheme of the front door offered for review will acquaint you with the names and location of the main units and elements. nine0005

Preparing the diagram

The drawing of the entrance metal door is a large-scale diagram of the door leaf, according to which the product will be assembled and installed, with the dimensions of the door frame marked on it, the locations of the stiffeners, hinges.

We arm ourselves with a tape measure and take measurements from the doorway.

The standard door size is 90 x 200 cm, if the actual dimensions of the opening are much larger than the data, it makes sense to install a separate block on top or on the side of the door leaf. nine0005

The side block can be made blind or hinged, and the top block can be closed with sheet metal, glazed or grated.

We also put all this on our drawing.