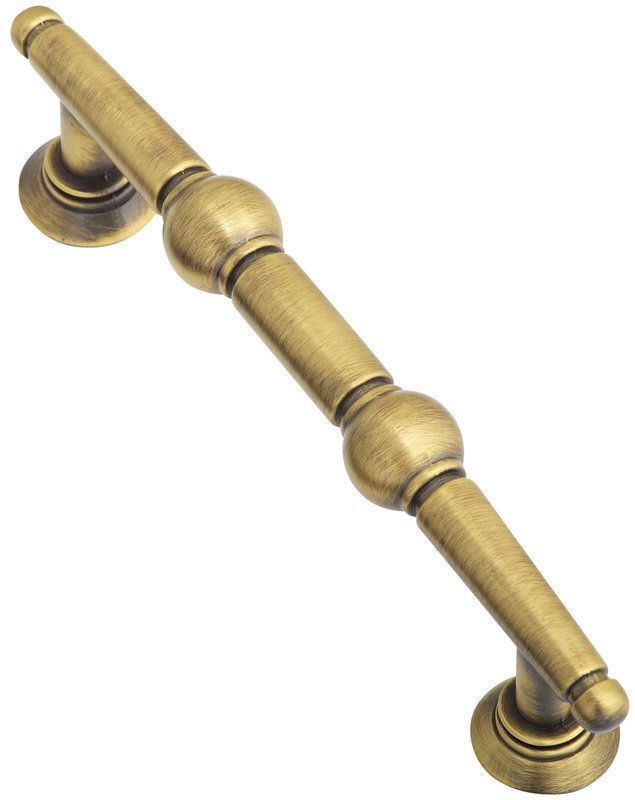

Clean antique brass hardware

How to Clean Brass Hardware to Make It Look Like New

By

Lauren Thomann

Lauren Thomann

Lauren Thomann is passionate about crafting and DIY home improvement, writing on both topics. While refurbishing her 1916 bungalow on her own, she shares lessons learned through her DIY and home improvement articles.

Learn more about The Spruce's Editorial Process

Updated on 11/08/22

The Spruce / Nelly Cuanalo

In This Article

-

Before You Begin

-

Instructions

-

FAQ

Project Overview

Some homeowners with older houses like the darkened patina that results as brass doorknobs, hinges, and other hardware begin to tarnish. It's even possible to artificially age new brass to get this antique look. But even if you want the metal in your home to look antique, it does not need to look corroded and unsightly with caked-on layers of tarnish and grime.

Tarnished brass hardware can be difficult to clean. It's easier when you use the right product or technique. There is a single product that can effectively clean brass hardware and other metals such as copper and stainless steel in a matter of minutes. Bar Keeper's Friend is a popular and effective metal cleaning product, but there is a variety of brass and metal cleaners available.

You can also make your own metal cleaner using baking soda and vinegar; it's not as effective but will work in situations where you want to remove some but not all of the patina.

Before You Begin

Carefully remove the hardware, making sure you do not strip the screws or damage the metal. If the screw slots are plugged with dirt or paint, you may need to scrape out the slots so that the screwdriver can grip the screw. A manual screwdriver works better than a drill driver to back out screws since brass is a fairly soft metal that is easily damaged.

Next, try to identify the type of metal. If it looks like brass, you'll need to figure out if the hardware is solid brass, or brass-plated. If it is solid brass, you will not have to worry as much about damaging the plating with an abrasive cleanser.

If it looks like brass, you'll need to figure out if the hardware is solid brass, or brass-plated. If it is solid brass, you will not have to worry as much about damaging the plating with an abrasive cleanser.

One simple method is to test with a magnet. Brass is a non-magnetic metal, so if a magnet is attracted to your hardware, it's likely comprised of a thin brass plating over an iron-based metal. In this case, you will need to be extra gentle in your cleaning and polishing to avoid abrading through the brass.

The Spruce / Nelly Cuanalo

Equipment / Tools

- Toothbrush and/or other soft-bristled brush

- Gloves

- Screwdriver

- Magnet (for identification of metal)

- Small bucket or old bowl

- Dish detergent (if needed)

Materials

- Cloth

- Bar Keeper's Friend or another metal cleaner

Instructions

-

Clean the Hardware With Lukewarm Water

With the hardware removed, wipe off any dust or debris with a lint-free cloth.

Submerge the items in lukewarm water and let them soak for a minute or two. If the hardware is very dirty, mix in a mild dish detergent to loosen the grime. After you remove the hardware from the water, move immediately to the next step without drying it.

Submerge the items in lukewarm water and let them soak for a minute or two. If the hardware is very dirty, mix in a mild dish detergent to loosen the grime. After you remove the hardware from the water, move immediately to the next step without drying it. The Spruce / Nelly Cuanalo

-

Sprinkle the Hardware With Powdered Cleaner

With the hardware fully wet, sprinkle on a powdered cleaning product so the metal is completely covered.

If you are using vinegar and baking soda, first brush the hardware with a layer of vinegar, then sprinkle on baking soda. The mild chemical reaction of vinegar combined with baking soda is what loosens the tarnish. When it starts to fizz, you will know it is working.

The Spruce / Nelly Cuanalo

-

Scrub Gently to Buff the Surface

Use a soft-bristled toothbrush to gently buff the surface. The cleanser will become paste-like and begin removing the tarnish. If there is a heavy tarnish build-up, it may take repeated scrubbing; add more water and metal cleaner as needed.

If you are using the baking soda and vinegar method, dip your toothbrush in a bowl of vinegar, and use that to buff the baking soda mixture on the metal.

It will be obvious as the tarnish starts to come off, but if you want to retain some of the antique patina, focus the toothbrush on the high points and avoid the crevices and edges.

The Spruce / Nelly Cuanalo

-

Rinse the Hardware

Once the metal is cleaned to your liking, use lukewarm water to rinse off any remaining cleaning solution. Next, take a damp lint-free cloth or paper towel to buff the hardware. Make sure each piece is dried completely to prevent rust or tarnish issues.

The Spruce / Nelly Cuanalo

Watch Now: Watch Now: Easy Ways to Refurbish Hardware

How to restore brass | Homes & Gardens

(Image credit: Unsplash/Flavio Amiel)

Restoring brass hardware can seem like a daunting task, especially if it's got years of tarnish build up or is a chore you've never tackled before. However, its actually surprisingly easy.

However, its actually surprisingly easy.

While slightly tarnished brass brings aged character to door fittings, creating an antique-style look, there is a fine line between a piece looking like an antique and one that looks corroded, unattractive and uncared for.

Thankfully, we've rounded up a host of easy ways to restore brass hardware that will help you get the shine back in your favorite pieces.

See more cleaning know-how on our dedicated page.

What is brass hardware?

(Image credit: Getty Images)

Brass hardware is simply hardware made from solid brass. There are lots of brass-plated and finished versions but solid brass hardware offers a longevity and quality that adds traditional character to a home.

'Cast, sheet or spun brass was widely used to make door and window furniture but requires regular polishing. Some pieces may be lacquered or brass plated,' says Roger Hunt, Period Living's renovation expert and author of Old House Handbook .

- See: How to clean cast iron – remove rust, reseason and refinish

How can you tell if hardware is brass?

(Image credit: Getty Images)

It is important to make sure that your hardware is actually made from brass before attempting these cleaning methods. If it is brass-plated or simply painted to look like brass, these methods can completely ruin your hardware.

Thankfully double checking is really easy. You can tell if hardware is brass by touching it with a magnet – if it sticks, it is not brass as brass isn’t magnetic.

If your hardware is not brass (as the magnet sticks to it), then gently washing with warm soapy water followed by a gentle rub with olive oil to chase out the water, is the best course of action and will have your hardware shining again in no time. Don’t polish it though as this can damage the plating.

If your magnet doesn’t stick and your hardware is brass then you have a wide variety of options to choose from, depending on the severity of the tarnishing.

Before starting any cleaning work though, you must remove your hardware. This will let you get in all the nooks and crannies as well as protecting your door. ‘Always keep the screws that came with each piece together with the hardware (I like to put the complete piece and fasteners in a plastic baggie),’ advises Jon Eaton the creative director of House of Antique Hardware .

- See: How to clean silver – an expert guide

Which products to use for restoring brass hardware

(Image credit: Unsplash/James Balensiefen)

Successful brass cleaning all comes down to the products you use. Whether you opt for store-cupboard essentials like lemon and salt or vinegar and baking soda or purchase a purpose-made cleaner, there are a few must-haves to complete your brass cleaning toolkit.

- A toothbrush will help you get into all the nooks and crannies;

- Fine wire wool will let you remove stubborn tarnishing without scratching your brass hardware;

- Olive oil is a great option to naturally polish your piece and repel any water that's been trapped as part of the cleaning process.

How to restore brass with lemon and salt

(Image credit: Future)

Create a paste using ¼ cup of salt with ½ cup of lemon juice, then rub into the brass with a soft toothbrush to remove tarnishing.

However, you must make sure you wash off the lemon juice with water as it's acidic and will corrode the brass hardware if left. Once washed and dry, rub with olive oil to chase out the water and preserve the shine.

How to restore brass hardware with baking soda and vinegar

It seems as though baking soda and vinegar can clean virtually everything and brass hardware is no exception.

Mix ½ cup of baking soda with 1 cup of white vinegar to create a paste (you can also add 2 tbsp of table salt if your piece is badly tarnished). The paste will fizz for a few seconds. Once the paste has stopped fizzing, rub on to your brass hardware in circular motions with a toothbrush. Let the paste sit for 30 minutes then rinse off.

Repeat if necessary, then rub with olive oil to protect the brass hardware and add shine.

This feature was created by H&G's sister brand, Period Living magazine

Subscribe to Period Living for more inspiration Period Living is a best-selling period homes magazine. A subscription provides you with all you need to know about caring for and improving a traditional house and garden.

How to restore heavily corroded vintage brass hardware

(Image credit: Unsplash/Jessica Knowlden)

Reclaimed brass hardware or vintage brass hardware can pose a greater challenge when it comes to restoration. These pieces may have not been cleaned for centuries. 'Brasso and a cloth won’t cut it, but luckily it’s not too expensive to have them machine polished,' says Paul Nash of Architectural Decor

'The restoration of brass hardware is an artform.' says Liz Gordon of Liz’s Antique Hardware . 'It requires stripping off old paint or removing aged finishes to arrive to the original patina of the base metal, then from there achieving the desired patina requires handwork and the use of a variety of techniques, like firing and buffing wheels for example. The results are rich patinas that may continue to age with time.'

The results are rich patinas that may continue to age with time.'

How to restore lacquered brass hardware

(Image credit: Unsplash/Brett Jordan)

Lacquered brass hardware has a tendency to peel, which then allows the brass beneath to tarnish in some spots.

‘This is one of the trickiest situations,’ says Jon Eaton. ‘Sometimes brass is lacquer coated to prevent it from tarnishing, but inevitably the lacquer begins to wear off. In this case the only solution is to remove the lacquer and repolish.’

To restore lacquered brass hardware, soak it in a paint stripper for a few minutes and then use steel wool to scrub the lacquer until fully removed. This can take some time as the lacquer is clear, making it hard to see the spots you have missed.

‘If you don’t remove every spec, your hardware will take on a spotted look,’ warns Jon Eaton. ‘However, you can identify any remaining lacquer residue by dipping the hardware in the brass ageing solution which will darken all the areas except those with lacquer. Don’t worry about the darkening effect of the ager as it will be removed by polishing.'

Don’t worry about the darkening effect of the ager as it will be removed by polishing.'

How to restore brass hardware that has been covered or partially covered with paint

(Image credit: Unsplash/Dan Counsell)

When it comes to restoring brass hardware that has been covered with paint, ‘I prefer the boiling method over using a paint stripper,’ says Jon Eaton. ‘Add hardware to low boiling water – if you have several pieces I suggest doing one piece at a time so as not to get parts mixed up. Let it boil for a few minutes until the paint wrinkles up on the metal.

‘Remove the hardware with tongs and lay on paper towels on a counter or cookie sheet. You don’t need to dry them off and you want to work quickly. Using the steel wool rub the paint off the metal. It may take some scrubbing in places, and come off easily in others. Simply rub and polish till all paint is removed. Use a utility knife to pry any paint out of crevices, like the heads of screws.

‘Repeat until all the paint is removed then rub lightly all over with the finest grade steel wool to polish. ’

’

- See: Cleaning tips - easy, eco-friendly and from the world's top experts

How to polish brass hardware

'Regular polishing will keep brass looking attractive,' advises Roger Hunt, Period Living's renovation expert. Though you must take care when doing this as some chemical polishes can cause harm if they come into contact with stone, wood or paintwork. 'When polishing,' continues Roger, 'make a cardboard or plastic template to fit around the fitting so adjoining surfaces are protected and cleaning is easier, and be sure to gently wipe off dirt with a soft, damp cloth'.

Having graduated with a first class degree in English Literature four years ago, Holly started her career as a features writer and sub-editor at Period Living magazine, Homes & Gardens' sister title. Working on Period Living brought with it insight into the complexities of owning and caring for period homes, from interior decorating through to choosing the right windows and the challenges of extending. This has led to a passion for traditional interiors, particularly the country-look. Writing for the Homes & Gardens website as a content editor, alongside regular features for Period Living and Country Homes & Interiors magazines, has enabled her to broaden her writing to incorporate her interests in gardening, wildlife and nature.

This has led to a passion for traditional interiors, particularly the country-look. Writing for the Homes & Gardens website as a content editor, alongside regular features for Period Living and Country Homes & Interiors magazines, has enabled her to broaden her writing to incorporate her interests in gardening, wildlife and nature.

Brass Hardware Cleaning Tips

Do you have brass handles on your kitchen cabinets? Any random table with brass construction in the living room? If they are old pieces, it is likely that they have lost their luster over time and need cleaning to shine again. Discover the tricks of pure brass fittings and give them back all their shine!

Brass does not rust, but over time tends to blacken due to exposure to various elements and especially processing. You can varnish the parts to keep them shiny, or you can clean them by following the steps we will share with you today. nine0003

Index

- 1 Before you start...

- 2 Clean brass fittings with vinegar

- 3 Doesn't work?

Before you start...

Make sure the parts you want to clean are actually brass. If they weren't and only had a cover or bath, you could damage them when trying to clean them. To test this, all you have to do is use a magnet. Solid Brass It will not be attracted by the magnetic force of a magnet whereas brass plated hardware will. nine0003

Have you done all the checks? After making sure that the fittings are made of unfinished brass, the next step is remove them to clean with more comfort. This is very difficult to do if they are enabled.

Clean brass hardware with vinegar

Start by cleaning hardware with hot soapy water , rubbing the parts with a very soft cloth or brush to avoid damaging them. The purpose of this cleaning is to remove any traces of dirt from the parts: grease, wax. .. Then dry them well and place them on a clean cloth. nine0003

.. Then dry them well and place them on a clean cloth. nine0003

Since the parts are clean and dry, now yes, our goal will be to remove that layer that blackens them (and protects them from other attacks) to restore their shine. For this we will use White Vinegar, solution that we all have on hand. Dip a cloth in vinegar and rub the pieces to a shine. If the pieces are not too blackened, this should be enough.

Not enough? To make the polish more effective, you can mix it with a glass of vinegar. nine0005 tablespoon of salt . Or, extend the time your items are exposed to vinegar by soaking them for an hour before wiping them down with a rag.

Doesn't work?

When the brass has become very blackened, it may be necessary to resort to . Commercial product is more aggressive. They are usually designed for copper, bronze or brass parts and come in small plastic containers.

If you are going to work with them, apply following the manufacturer's instructions . It is usually sufficient to apply the product to the product with a dry cloth if the surface is smooth, and with an old toothbrush if the surface is beveled or tilted, let it soak in and polish again.

It is usually sufficient to apply the product to the product with a dry cloth if the surface is smooth, and with an old toothbrush if the surface is beveled or tilted, let it soak in and polish again.

How did you test to bring back the shine of to brass parts is very simple. Simply clean the parts, let them dry and then polish them with the appropriate product. Dare you clean the brass fittings in your wardrobe now that you know how?

nine0002 The content of the article complies with our principles of editorial ethics. To report a bug, click here.

Door handle history

Modern, functional and diverse in design, wholesale door handles have little in common with their ancestor - the very first door handle. It is not known for certain where and when she appeared. But it is clear that the need for door handles arose simultaneously with the appearance of the first wooden door panels, that is, approximately in the 4th century BC. nine0003

First knob: pure function

The age of 2. 5 thousand years allows us to call the door handle one of the oldest inventions of mankind. At the dawn of its life, the handle was pure function: it served to open and close the door, and nothing more. There is reason to believe that the oldest door handles were made of wood and were staples in design. It was for such a handle that it was convenient to take to pull the door towards you or push it. There was no need for rotary handles for a long time, since the locking mechanism with which such a handle would be associated has not yet been invented. nine0003

5 thousand years allows us to call the door handle one of the oldest inventions of mankind. At the dawn of its life, the handle was pure function: it served to open and close the door, and nothing more. There is reason to believe that the oldest door handles were made of wood and were staples in design. It was for such a handle that it was convenient to take to pull the door towards you or push it. There was no need for rotary handles for a long time, since the locking mechanism with which such a handle would be associated has not yet been invented. nine0003

Oddly enough, handles of this original form have been preserved in our time. They are quite widely used, for example, in baths and saunas. They can still be seen in rural areas today: on gates, in utility rooms, and sometimes even on the front doors of residential buildings. Perhaps none of the equally ancient inventions is as common in its original form as the doorknob!

Metal handles - only for the rich

Over time, metal handles began to appear. At first they were quite simple, but soon they began to receive more attention. Door handles took on more and more elegant and interesting forms. Masters made twisted handles, forged them in the form of climbing plants ... There were also more complex forms: figures of animals and people, etc.

At first they were quite simple, but soon they began to receive more attention. Door handles took on more and more elegant and interesting forms. Masters made twisted handles, forged them in the form of climbing plants ... There were also more complex forms: figures of animals and people, etc.

By the way, the very name "door handle" (in English - door handle) is considered to have come from Ancient Rome, where handles were often made in the shape of a hand. It was no longer just a function pen, but also a symbol pen: before entering the house, the guest symbolically “shaked hands” with the owners of the house, voluntarily or involuntarily showing his disposition. By the way, hand-shaped products were subsequently widely used in Europe. For example, Renaissance masters often decorated their front doors with them. Such pens can still be seen today in the ancient buildings of many European cities. nine0003

Naturally, only quite rich people could afford such doorknobs. Ordinary people still used cheap and malleable wood.

Ordinary people still used cheap and malleable wood.

Medieval talking pen

Craftsmanship improved - and the door handle improved. More precisely, its shape, because functionally it was still a push-pull device. Door handles were installed mainly on the front doors. This was explained quite simply: until the 17th century in Europe (and we consider the history of the doorknob on the example of Europe), there were actually no rooms, and, accordingly, no interior doors. The houses were a single room, if it was separated by walls, then instead of doors they used open wide arched openings. nine0003

But the handles on the front doors of that time show us a gallery of the most bizarre forms! Some of them may well be considered works of art, they were so elegant and stylish! The variety of antique door handles is so great that it has become the reason for the appearance of legends. For example, it is believed that no two door handles are the same on the island of Malta. Don't believe? Come and see for yourself!

Don't believe? Come and see for yourself!

Around the Middle Ages, a ring-shaped door handle appeared, the functionality of which was already somewhat wider. In addition to actually opening the door, it served as a hammer, with which guests could knock on the door and notify the hosts of their arrival. nine0003

It is interesting how widely symbolism began to be used in the Middle Ages in the manufacture of door handles. We already know that metal (bronze, copper) door handles testified that the owner of the house was a wealthy person belonging to the upper class. The fantasy of the nobility turned the doorknob into a kind of "passport", which could tell a lot about the owners of the rich house, whose door it decorated.

For the richest people, pens were made of precious metals. If the owner of the house belonged to a noble class, then he could afford a pen that repeats the elements of the family coat of arms. In the homes of wealthy artisans or merchants, door handles often reflected the essence of the business in which the person was engaged. nine0003

nine0003

Somewhat later, already in the 18th-19th centuries, famous architects often made a pen a kind of autograph. For example, the Russian architect Andrei Shtakenshneider “crowned” the doors of buildings built according to his designs with handles in the form of a paw squeezing a ball. Unusual and very inventive, isn't it?

The industrial revolution is the mother of the modern pen

In the first third of the 19th century, the first latch locks appeared in Great Britain, first of an overhead design, and then of a mortise. These inventions were associated with the emergence of a method for melting cast iron into iron, which led to a real breakthrough in the industry. nine0003

The first latches were set in motion by turning a round handle - the so-called knob. It was a ball attached to the base. The torque was transmitted to the mechanism from the lock handle through a completely modern square-section rod, which is now simply referred to as a square. The only difference between this hand-forged rod and the modern square was the size of the section: in the 19th century, its side was 7 mm, while today the generally accepted world standard is 8 mm. nine0003

The only difference between this hand-forged rod and the modern square was the size of the section: in the 19th century, its side was 7 mm, while today the generally accepted world standard is 8 mm. nine0003

During the eighteenth century, Great Britain firmly established itself as a powerful industrial power, developing production in all areas, including in the field of door fittings. To keep the country on this pedestal, the government went to extreme measures. For example, a restriction was introduced on the export of industrial machine tools, and skilled craftsmen were even forbidden to travel outside the country. This, by the way, explains the fact that most of the locks and door handles in Europe and even in the United States until 1830 were of English manufacture! nine0003

Gradually, rotary-type door handles were modified, more and more approaching modern ones. So, for example, the cross section of the square increased to 7.6 mm. The size of the rotary knob increased, the ball flattened, and the knob began to take on a mushroom shape.

In the 1940s, foundry production began to develop. However, mass-market brass and bronze cast knobs were fairly simple in design and differed little from their forged predecessors. Casting of more complex forms, although it existed, was too expensive, and only very rich people could afford such door fittings. "Designer" products for the mass market will appear three decades later, with the development of injection molding technology. nine0003

Meanwhile in the States…

Despite all the efforts of Great Britain, a new impetus in the development of both design and construction of door handles was nevertheless received overseas - in the United States of America. By the middle of the 19th century, the United States became the state with the fastest growing industry. Industrialization and powerful population growth resulted in a hitherto unprecedented flurry of inventions. Think about it: in the 1850s, 36 times more patents were issued annually than in 1811, on the eve of the war! nine0003

The inventors did not bypass the door fittings. So, in 1876, Lewis Norton invented and patented a pneumatic door closer. And two years later, the Patent Office registered a patent for Osborne Dorsey for a combined latch handle. The mechanism was quite bulky - almost the width of the door leaf. However, this was the beginning of a new era in the history of door handles.

So, in 1876, Lewis Norton invented and patented a pneumatic door closer. And two years later, the Patent Office registered a patent for Osborne Dorsey for a combined latch handle. The mechanism was quite bulky - almost the width of the door leaf. However, this was the beginning of a new era in the history of door handles.

By the end of the 19th century, we should still return to Europe, where events interesting for our topic also unfolded. First, galvanization was invented in France. This process is still used today in the production of door fittings. In particular, all NORA-M wholesale door handles have a multi-layer galvanic coating. Electroplating made it possible to give cheaper metals the brilliance and color of more noble metals. And, in addition, it significantly increased the anti-corrosion properties of materials. nine0003

But the most important thing was not even this, but the fact that in the second half of the 19th century in Europe (and soon in the USA) . .. the first push door handles appeared.

.. the first push door handles appeared.

The beginning of the 20th century: the struggle of structures

It is curious that for quite a long time lever handles were lost before the popularity of knobs. This was partly due to economics. For example, before the First World War, industrialists preferred to save metal, and produced rotary knobs with heads made of glass or wood. nine0003

However, after the war, manufacturers of door fittings again turned their attention to the lever handle. It was during these years that the square receives the usual cross section of 8 mm, a sleeve is added to the mechanism, which reduces the friction of parts.

In 1925, an exhibition in Paris featured many Art Deco push-type door handles, a new architectural trend that quickly gained popularity. So a mass-produced door handle becomes, if not an object of art, then an interior decoration - for sure! nine0003

Between the two world wars, lever handles gradually win back the market from rotary ones. At the same time, not expensive bronze and brass, but cheaper materials began to be used for their production: first steel, and later aluminum.

At the same time, not expensive bronze and brass, but cheaper materials began to be used for their production: first steel, and later aluminum.

During the Second World War, metal doorknobs were again replaced by glass and wood, all for the same reasons. And after the end of the war, nothing hinders the development of our heroine - the doorknob. The design is being improved, and the appearance is striving for simplicity - this is the main principle of the development of lever handles in the late 40s and 50s of the XX century. Even the slats gradually faded into the shadows, making room for more concise outlets. nine0003

It is curious that at the same time there was a certain redistribution, which is still preserved. The West (namely, the USA) chose knobs. East (Europe) switched to lever door handles. It is difficult to understand why this happened. Nevertheless, in the States today, most of the handles are rotary. Although purely from a user point of view, push handles are much more convenient.