Antique furniture restoration products

Furniture Restoration Products & Supplies | Van Dyke's Restorers

Upholstery Strap Springs 205996

Tambour Glue 205857

Tambour GlueThe average rating for this product is 5 out of 5 stars

Silputty 206038

SilputtyThe average rating for this product is 5 out of 5 stars

Restorers Shiny Nickel Upholstery Tack 226166

Restorers Old Nickel Round Upholstery Tack - 7/16 Inch 226157

Por-A-Kast 206039

Por-A-KastThe average rating for this product is 4 out of 5 stars

Restorers Antique Brass Upholstery Tack 226129

Restorers Dark Old Gold Round Upholstery Tack - 1 Inch 226143

Restorers French Natural Upholstery Tack - 7/16 Inch 226149

Restorers Burnished Brass Upholstery Tack - 9/32 Inch 226140

Restorers Classic #7 x 1 Inch Slotted Flat Head Screws - Pack of 20 225615

Flexible Upholstery Nail Strip 205694

Restorers Burnished Brass Upholstery Tack - 13/16 Inch 226139

Acorn Flooring Nail 205980

Restorers Old Nickel Round Upholstery Tack - 5/8 Inch 226156

Restorers Rosette Upholstery Tack 226127

Restorers Bronze Renaissance Hammered Upholstery Tack 226137

Upholstery Tack Spacer 205697

Restorers Dark Old Gold Round Upholstery Tack - 3/4 Inch 226144

Sunburst Upholstery Tack 210368

Designs of Distinction Apex 3 Inch Corner Straps 236845

Restorers Oxford Sunflower Upholstery Tack 226161

Restorers Copper Upholstery Tack - 1/2 Inch 226141

Restorers Old Nickel Round Upholstery Tack - 7/8 Inch 226158

Restorers Classic Slotted Pan Head Screws - Pack of 20 225970

Restorers Classic #5 x 5/8 Inch Slotted Oval Head Screws - Pack of 20 225612

Restorers Antique Brass Honeycomb Upholstery Tack 226126

Restorers Old Gold Upholstery Tack 226154

Restorers Classic #5 x 5/8 Inch Slotted Flat Head Screws - Pack of 20 225611

Restorers Old Brass Round Upholstery Tack 226150

Restorers Shiny Nickel Plain Upholstery Tack 226165

Restorers Shiny Nickel Hammered Head Upholstery Tack 226164

Premier Copper Sink Wax And Cleaner 210621

Restorers Classic #5 x 5/8 Inch Slotted Round Head Screws - Pack of 20 225613

Restorers Pyramid Bronze Renaissance Upholstery Tack 226162

Restorers . 66 Special Upholstery Tack 226124

Restorers Copper Upholstery Tack - 3/8 Inch 226142

Designs of Distinction Straight Furniture Foot Mounting Plate 239249

Designs of Distinction Decorative Aluminum Strapping 242154

Designs of Distinction Angle Furniture Foot Mounting Plate 239156

Designs of Distinction Heavy Duty Straight Foot Mounting Plate 239228

Designs of Distinction Decorative Aluminum Strap 242153

Designs of Distinction 3/8 Inch x 48 Inch Brass Strap 239059

Designs of Distinction 3/8 Inch Flat L-Shape Corner Strap 239058

Small Dot Upholstery Tack 210369

Restorers Classic #7 x 1 Inch Phillips Flat Head Screws - Pack of 20 225614

Restorers French Natural Upholstery Tack - 11/16 Inch 226148

Acorn Tapered Period Box Nail 206440

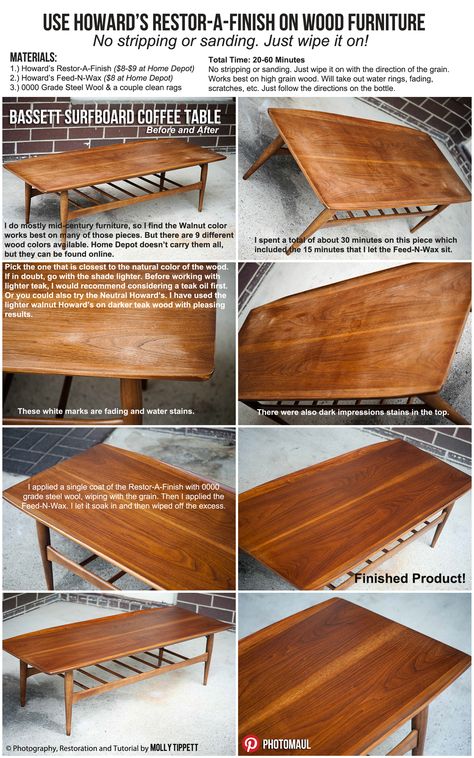

Antique Furniture Refinisher - Furniture Restoration

← Wood Preparation

Minwax® Antique Furniture Refinisher is a low viscosity, amber colored blend of solvents and wood conditioners used to dissolve varnish, shellac, and/or lacquer on all types of wood surfaces without harming the wood.

- Contains natural wood oils that penetrate and condition wood

- Does not remove paint or polyurethane

- Perfect product for antique wooden furniture restoration

WHERE TO BUY

Coverage

N/A

For Use In Location

Interior

Package Sizes

1-Quart

Reviews

Get Inspired

See what’s possible, and then make it happen. Tag @minwaxusa on Instagram to have your project featured.

View More Inspiration

-

Preparation Warning

Removal of old paint by sanding, scraping or other means may generate dust or fumes that contain lead. Exposure to lead dust or fumes may cause brain damage or other adverse health effects, especially in children or pregnant women.

Controlling exposure to lead or other hazardous substances requires the use of proper protective equipment such as a properly fitted respirator (NIOSH approved) and proper containment and cleanup. For more information, call the National Lead Information Center at 1-800-424-LEAD (in US) or contact your local health authority.

Controlling exposure to lead or other hazardous substances requires the use of proper protective equipment such as a properly fitted respirator (NIOSH approved) and proper containment and cleanup. For more information, call the National Lead Information Center at 1-800-424-LEAD (in US) or contact your local health authority. -

APPLICATION STEPS

- Wear rubber gloves and protective glasses. Pour 4-6 ounces of Minwax® Antique Furniture Refinisher into a metal or glass container.

- Dip a piece of fine steel wool (000) into the Minwax® Antique Furniture Refinisher and squeeze out excess.

- Rub gently in small circles until old finish is dissolved. Repeat process as needed. Replace Minwax® Antique Furniture Refinisher liquid in pan when it becomes thick.

- When completed, go back over entire surface with clean steel wool and clean Minwax® Antique Furniture Refinisher. Be sure any lap marks are removed.

-

CAUTIONS

CAUTIONS: CONTAINS ACETONE, TOLUENE AND METHANOL. POISON- GET MEDICAL ATTENTION. Contents are EXTREMELY FLAMMABLE. Keep away from heat, sparks, and open flame. Vapors will accumulate readily and may ignite explosively. During use and until all vapors are gone: Keep area ventilated- Do not smoke- Extinguish all flames, pilot lights, and heaters- Turn off stoves, electric tools and appliances, and any other sources of ignition.

VAPOR HARMFUL. Use only with adequate ventilation. To avoid overexposure, open windows and doors or use other means to ensure fresh air entry during application and drying. If you experience eye watering, headaches, or dizziness, increase fresh air, or wear respiratory protection (NIOSH approved) or leave the area. Avoid contact with eyes and skin. Wear rubber gloves and safety goggles during use. Wash hands after using. Keep container closed when not in use. Do not transfer contents to other containers for storage. FIRST AID: In case of eye contact, flush thoroughly with large amounts of water for 15 minutes and get medical attention. For skin contact, wash thoroughly with soap and water. In case of respiratory difficulty, provide fresh air and call physician. If swallowed, call Poison Control Center, hospital emergency room, or physician immediately. DELAYED EFFECTS FROM LONG TERM OVEREXPOSURE. Contains solvents which can cause permanent brain and nervous system damage. Intentional misuse by deliberately concentrating and inhaling the contents can be harmful or fatal.

VAPOR HARMFUL. Use only with adequate ventilation. To avoid overexposure, open windows and doors or use other means to ensure fresh air entry during application and drying. If you experience eye watering, headaches, or dizziness, increase fresh air, or wear respiratory protection (NIOSH approved) or leave the area. Avoid contact with eyes and skin. Wear rubber gloves and safety goggles during use. Wash hands after using. Keep container closed when not in use. Do not transfer contents to other containers for storage. FIRST AID: In case of eye contact, flush thoroughly with large amounts of water for 15 minutes and get medical attention. For skin contact, wash thoroughly with soap and water. In case of respiratory difficulty, provide fresh air and call physician. If swallowed, call Poison Control Center, hospital emergency room, or physician immediately. DELAYED EFFECTS FROM LONG TERM OVEREXPOSURE. Contains solvents which can cause permanent brain and nervous system damage. Intentional misuse by deliberately concentrating and inhaling the contents can be harmful or fatal. WARNING: This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. DO NOT TAKE INTERNALLY. KEEP OUT OF THE REACH OF CHILDREN.

WARNING: This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. DO NOT TAKE INTERNALLY. KEEP OUT OF THE REACH OF CHILDREN.

-

Minwax® Product Warranty

SATISFACTION GUARANTEE LIMITED WARRANTY. This warranty is made to you, the product purchaser who owns the property where the product is applied. This warranty is not transferable except that if a contractor purchased and applied the product to the property for you, then the warranty is transferable to you. If this product, when applied and maintained according to product application and maintenance instructions to a properly prepared surface, fails to perform to your complete satisfaction, Minwax shall, upon presentation of proof of purchase, either replace an equivalent quantity of product free of charge or refund the original purchase price. For a replacement or refund please contact customer service at 1-800-523-9299.

This warranty shall not apply to any defect, damage, or product failure resulting from improper surface preparation, structural defects, environmental damage, failure of a previous product, deterioration or defect in the underlying substrate, or improper application or maintenance of the product. Your exclusive remedy, and Minwax's sole liability, under this warranty is the replacement of product or refund and does not include labor or costs associated with the application or removal of any product. IN NO EVENT SHALL MINWAX BE LIABLE FOR ANY TYPE OF INCIDENTAL, CONSEQUENTIAL, SPECIAL, EXEMPLARY, PUNITIVE, OR INDIRECT DAMAGES WHETHER OR NOT PURCHASER IS ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. ALL IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL HAVE THE SAME DURATION AS THE ABOVE EXPRESS WARRANTY. Some states do not allow limitations on how long an implied warranty lasts or limitations on incidental or consequential damages, so portions of the limitations above might not apply to you.

This warranty shall not apply to any defect, damage, or product failure resulting from improper surface preparation, structural defects, environmental damage, failure of a previous product, deterioration or defect in the underlying substrate, or improper application or maintenance of the product. Your exclusive remedy, and Minwax's sole liability, under this warranty is the replacement of product or refund and does not include labor or costs associated with the application or removal of any product. IN NO EVENT SHALL MINWAX BE LIABLE FOR ANY TYPE OF INCIDENTAL, CONSEQUENTIAL, SPECIAL, EXEMPLARY, PUNITIVE, OR INDIRECT DAMAGES WHETHER OR NOT PURCHASER IS ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. ALL IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL HAVE THE SAME DURATION AS THE ABOVE EXPRESS WARRANTY. Some states do not allow limitations on how long an implied warranty lasts or limitations on incidental or consequential damages, so portions of the limitations above might not apply to you. This warranty gives you specific legal rights, and you may have other rights, which vary from state to state.

This warranty gives you specific legal rights, and you may have other rights, which vary from state to state.

Minwax® Antique Oil Finish

Minwax® Antique Oil Finish is an oil-based protective finish that gives wood a soft, hand-rubbed lustre. It’s durable, easily maintained, and highly resistant to staining.

SEARCH ALL PRODUCTS

Oil and furniture

HOME – RESTORATION WORKS – Oil and furniture

Polish finish.Which furniture can be oiled and which is undesirable?

Oil and wax are intended for caring for solid natural wood and are contraindicated for veneered furniture. Especially old, vintage and antique. Getting on the surface of damages (chips, scratches, dents), or under the exfoliated veneer, oil and wax prevent restoration gluing. nine0008

Anyone can buy wood oil and cover their furniture with it. It does not require any experience or special tools. The main thing is to choose the right product. Terrace oil, garden furniture oil and home wood furniture oil have different compositions. What is suitable for parquet may not be suitable for terrace boards. If you choose the right product from a reliable expensive company, do everything according to the instructions, the result will be amazing. The tree is instantly transformed. It acquires a well-groomed, noble appearance, and garden furniture and a terrace will last for many years. nine0003

It does not require any experience or special tools. The main thing is to choose the right product. Terrace oil, garden furniture oil and home wood furniture oil have different compositions. What is suitable for parquet may not be suitable for terrace boards. If you choose the right product from a reliable expensive company, do everything according to the instructions, the result will be amazing. The tree is instantly transformed. It acquires a well-groomed, noble appearance, and garden furniture and a terrace will last for many years. nine0003

One question remains. If everything is so good with oil, why does scientific restoration not favor it? In furniture stores from well-known manufacturers, neither waxed nor oiled furniture is sold? And the restorers of the largest museums in the world do not refresh their exhibits with this wonderful product either.

The only place where you can find waxed or oiled furniture is in antique shops selling used European furniture.

The Internet is full of videos called "How to oil furniture?" But, pay attention. All work is carried out on the array, and the master classes are filmed either in small handicraft workshops, or are an advertisement for the manufacturer. nine0003

All work is carried out on the array, and the master classes are filmed either in small handicraft workshops, or are an advertisement for the manufacturer. nine0003

This happens because oil and wax materials are not durable. The exception is hot impregnation produced on industrial equipment or wood coating products, which are only called oils, but are actually a product of the paint and varnish industry. In all other cases, wood oil is more of a hobby product. It is intended for temporary protection, fast "rejuvenation" of a covering or care of furniture.

Oil does give the effect of an expensive finish, but not for long. nine0009

It can be used to cover solid wood furniture that is not planned to be restored in the near future. Oil applied to old veneered furniture penetrates under the peeled veneer. It complicates restoration, provokes the appearance of new damage and pollution.

In the photo, the sideboard is polished. It was made by the master manually, within two weeks. She will remain so for many years to come.

She will remain so for many years to come.

With oil, the same finish can be obtained in a couple of hours, but the effect will not last long. The conclusion suggests itself. nine0003

The price of restoration for covering furniture with oil should be several times lower than for polishing.

Restoration oil

Our workshop categorically does not use oil for restoration for the following reasons.

When restoring furniture, you have to glue, putty and paint a lot. Veneer, threads, overlay decor are glued. Putty closes up small cracks, scratches and chips. Separate damages have to be touched up. The main condition for a successful result of gluing, painting and varnishing is the degreasing of the surface. nine0003

In order for everything to stick together, paint over and putty well, the surfaces must be cleaned, leveled and, of course, degreased.

After the entire carpentry part of the restoration is done, the item is finished. Let's go back to what everyone knows. After priming, wood, inserts, fillers and touch-ups change their color. There are small defects that were invisible before finishing. In this case, the restorer finalizes the thing. Something once again glues, tints and putty. Then the final finishing follows and the item is handed over to the customer. nine0003

Let's go back to what everyone knows. After priming, wood, inserts, fillers and touch-ups change their color. There are small defects that were invisible before finishing. In this case, the restorer finalizes the thing. Something once again glues, tints and putty. Then the final finishing follows and the item is handed over to the customer. nine0003

Now imagine that after the first stage of restoration, we covered the tree not with pure varnish, but with oil.

The oil has penetrated into all the cracks, climbed into the smallest cracks, penetrated under the peeled veneer. If, suddenly, in the process of finishing it turns out that somewhere it is necessary to glue, repaint or putty, the restorer will no longer have such an opportunity. All surfaces are already oiled and nothing can stick to them.

DO NOT oil finish furniture in need of restoration. nine0009

Buy wood oil

Before you do something, it's a good idea to define your goals and objectives. If the task is to restore your furniture professionally, it is better not to take risks and give it to a restorer. If the task is to engage in creativity at your leisure, you will get a pastime. In the case of a serious intention to master the technique of wood processing with oil, you will have to study the properties of various types of impregnations and finishes, understand the range of oils for wood, furniture, parquet, deck and terrace boards. nine0003

If the task is to restore your furniture professionally, it is better not to take risks and give it to a restorer. If the task is to engage in creativity at your leisure, you will get a pastime. In the case of a serious intention to master the technique of wood processing with oil, you will have to study the properties of various types of impregnations and finishes, understand the range of oils for wood, furniture, parquet, deck and terrace boards. nine0003

What is sold in shops called oil for wood, furniture, parquet, decking is a product of the paint and varnish industry. It contains the oil itself, which has undergone special processing, as well as desiccants, fillers, fragrances, dyes. How to paint them is described in the instructions.

In the old days, floors and walls were covered with plain boiled butter. Mostly hemp or sunflower. Cooking, or calcination, is necessary to remove moisture and organic residues from the crude oil that have survived after pressing. Boiling the oil increases its viscosity and shortens the drying time. Oil that has undergone heat treatment is called drying oil. Dries for a long time, smells bad, the coating is not durable. Currently, it is mainly used for rough finishing as a primer for painting with oil paints. nine0003

Oil that has undergone heat treatment is called drying oil. Dries for a long time, smells bad, the coating is not durable. Currently, it is mainly used for rough finishing as a primer for painting with oil paints. nine0003

There is a scope for wood oil where it is indispensable. To this day, the technology of oil impregnation of gun butts, cutting boards, wooden utensils, boards on decks and terraces has retained its relevance, but more on that below.

Treat wood with oil

Oil impregnation cannot be replaced by any finish in the manufacture of rifle stocks, knife handles, cutting boards.

Why are hunting rifle stocks and cutting boards soaked in oil rather than varnished? nine0003

When dried, the varnish forms a thin, durable, wear-resistant film, thereby protecting the wood from dirt and giving it a special beauty. Unfortunately, this film is not elastic. The tree, absorbing moisture in nature and drying indoors, periodically changes its size. Let it be a fraction of a millimeter, but the area of \u200b\u200bconnecting it with a varnish film periodically changes. Drying, the tree becomes smaller, when moistened, it increases. Naturally, the lacquer film peels off from such exercises. nine0003

Drying, the tree becomes smaller, when moistened, it increases. Naturally, the lacquer film peels off from such exercises. nine0003

Oils practically do not form films. Penetrating into the pores of the tree, fill them. Over time, the oil in the pores of the tree polymerizes, turning into drying oil, thereby strengthening the surface layer of the wood.

Polymerization is the process of formation of a high molecular weight substance (polymer) by repeated attachment of molecules of a low molecular weight substance to active centers in a growing polymer molecule.

Unfortunately, cold oil molecules do not penetrate deep into the hollow tubes of wood vessels. Quickly volatilize and are removed. nine0003

The vessels of the tree are not empty, but filled with air. If you apply oil to wood, it will not go deep into the pores. He is not allowed air. Therefore, to impregnate wood with oil, the air must first be somehow expelled from the pores. There are two ways.

There are two ways.

Restorers often argue about what is right. TANGENTAL, TANGENTIAL or TANGENTAL. Merchants in veneer and an array of valuable breeds simply call it tangent. When I, 40 years ago, studied at the Forestry Engineering Institute, it was customary at the Department of Wood Science to call such a cut TANGENTAL. Therefore, I still call this kind of cut that way. The main thing is not who is right, but that they understood me. nine0009

Wood impregnation with oil

The temperature of the hot oil must be above the boiling point of water, but below the charring of the wood. Wooden handles of hunting knives, hilts of cold weapons, handles of expensive canes, fingerboards for guitars have long been dipped in hot oil. The air expanded from heating, came out of the pores of the wood, and the voids were filled with oil molecules, thereby giving the products a beautiful look and strength.

Naturally, when oiling the teak boards of the deck of the ship, the ancient sailors did not lower them into huge vats of hot oil. Processing work was carried out on a hot sunny day in the sun. The oil was poured onto the deck, dispersed with a mop and left to bask in the sun for some time. The deck was hot under the hot sun, oil penetrated into the pores. nine0003

The second method is impregnation with oil under vacuum. Air escapes, freeing the pores, and oil molecules rush in its place.

What kind of oil to impregnate wood

Traditionally, natural vegetable oils are used to impregnate wood. Oil suitable for wood impregnation should not contain impurities, protein and coloring substances. At the same time, the removal of protein and organic coloring substances is achieved by heating the oil already to a temperature of 120-130 degrees in the presence of bleached clay in an amount of 5-10% by weight of the oil. Oil calcination can be successfully done at home. nine0003

nine0003

In production, an oil that does not emit turbidity when heated to 300 degrees is called varnish or refined. Each type of oil used for impregnation corresponds to the established indicators: specific gravity, color, solubility, viscosity, refractive index, sludge, acid number, saponification number, iodine (bromine) number.

The grade, purity and quality of the wood impregnation oil is determined by chemical analysis in the laboratory.

The classification of wood oils is based on their ability to dry out. The oil, applied in a thin layer on a non-absorbent surface, dries out (Cures) after a few days, forming a thin film of varying degrees of strength. According to their ability to dry, oils are divided into five groups. nine0003

Drying oils

Oils of this group are characterized by relatively fast drying (5-6 days). The dried film does not soften, does not melt and is almost insoluble in organic solvents. Oils of this type include: linseed, hemp, perilla (derived from perilla oil plant). This group also includes wood (tung) oil, which has the highest drying rate.

This group also includes wood (tung) oil, which has the highest drying rate.

Linseed oil

The most common in the production of varnishes and varnishes. It is obtained from flax seeds containing 32-33% oil. nine0003

Hemp oil

Obtained from hemp seeds containing 28-35% oil. It has a greenish tint. It is used for the production of drying oils and varnishes; dries slower than linen.

Perilla oil

Trade name "Caucasian" or "Ukrainian". It is prepared from the seeds of the annual perilla plant. In terms of fatty acid composition and film quality, this oil is close to linseed oil. Raw perilla oil has the property of collecting on surfaces such as glass in droplets. After heating to 200 degrees, this property disappears. In the production of varnishes and drying oils, it can completely replace linen. nine0003

Wood or tung oil

It is also called "wooden". It is extracted from the seeds of the tung tree by pressing. The average oil content in the seeds is 50%.

The average oil content in the seeds is 50%.

Homeland of wood oil - Japan and China. Currently, tung trees grow in the Caucasus. Tung oil has a yellow color of varying intensity. Has a strong unpleasant odor. Toxic! Dries much faster than linen. Its film is harder than that of linen. The resulting film is dull, reminiscent of frost on glass. nine0003

After heating the wood oil to 120 degrees, the haze disappears. Oil behaves peculiarly when heated to high temperatures; if it is quickly heated to 300-310 degrees, then after 3-5 minutes it will begin to thicken, hardening into a gelatinous transparent mass, or, as they say, coagulates. Therefore, the processing of wood oil in the production of varnishes must be carried out at lower heating temperatures or mixtures of wood oil with linseed or other oils should be used.

nine0035 Semi-drying oils These oils dry much more slowly than linseed type oils. Dried films are able to soften and melt again. They are easily soluble. Poppy, walnut, sunflower, soybean oils can be used to impregnate wood to a very limited extent.

Poppy, walnut, sunflower, soybean oils can be used to impregnate wood to a very limited extent.

Poppy seed oil

Obtained by pressing poppy seeds. The average oil content in the seeds is 40 to 50%. In terms of drying speed, poppy oil is only slightly inferior to linseed oil. On a glass plate, it dries within 6-9days. The high cost of poppy oil makes it difficult to widely use it for the preparation of drying oils and for impregnating wood.

Due to its colorlessness and ability not to change the colors of paints, poppy oil is used in the manufacture of paints for painting.

Nut oil

Obtained from the fruits of the walnut tree. Due to the high cost in the furniture industry is not used. Occasionally used for the manufacture of high quality oil paints. nine0003

Sunflower oil

Obtained from sunflower seeds. The oil content in the seeds is 28-35%. Fresh sunflower oil dries on a glass plate for 8-12 days. The drying time of the oil is greatly reduced by the addition of desiccants. So, when 2% manganese resinate is added to raw oil, it dries out within 20-24 hours.

The drying time of the oil is greatly reduced by the addition of desiccants. So, when 2% manganese resinate is added to raw oil, it dries out within 20-24 hours.

Soybean oil (bean oil)

Derived from soybeans. It is yellowish or yellowish brown in color. Applied to the surface in a thin layer, it dries out within 8-12 days. Drying oil films from soybean oil tend to soften and are sticky. Soybean oil is best used in a mixture with linseed or peryl oil. nine0003

Non-drying oils (olive cottonseed)

These oils dry out only with the addition of desiccants, but even in the presence of the latter, the films are sticky.

Olive oil is obtained by pressing the fruits of the olive tree. The oil is non-drying.

Cottonseed oil

Produced from the seeds of various types of cotton. It belongs to the group of non-drying oils and is not suitable for wood impregnation in any form.

nine0002 Tall oil Tall oil is a by-product of pulp production. It is a dark brown viscous liquid with an unpleasant odor. Tall oil consists of a mixture of fatty and resin acids, as well as various neutral and oxidized substances.

It is a dark brown viscous liquid with an unpleasant odor. Tall oil consists of a mixture of fatty and resin acids, as well as various neutral and oxidized substances.

Lamp oil

According to the official version, lamp oil is made from refined olive oil. In the 20th century, flavored vaseline oil was widely used as lamp oil. nine0003

B azeline lamp oil

It is a highly refined mineral oil. Purified petroleum jelly oil does not smoke, does not go rancid, and does not absorb foreign odors. In addition, it evenly impregnates the wick and gives much less soot compared to vegetable oils.

Mineral oils

Mineral oils are by-products that form during the refining of petroleum. Vaseline oil is the most common in everyday life. Thanks to special processing, vaseline oil is found on sale in solid, mushy and liquid form. nine0003

Vaseline oil or liquid paraffin

Non-drying. Does not contain harmful organic substances and their compounds. Widely used in medicine, cosmetics, industry.

Does not contain harmful organic substances and their compounds. Widely used in medicine, cosmetics, industry.

Teak oil (trade term)

Teak is a beautiful, expensive tree. No oil is extracted from it. The manufacturer took its name in order to attract the attention of the buyer. Teak oil contains at least three plant components and synthetic additives. Usually, vegetable oils of flax, soybean and tung tree seeds are used as the main raw material for its manufacture, and synthetic substances are added as regulators and improvers. nine0003

Danish oil (trade term)

It got its name from furniture made in Denmark. Furniture was made from expensive wood and was highly valued. In the first half of the 20th century, the English firm of Sidney Rustin created an oil composition with additives and coloring additives that could imitate expensive woods; this composition became known as Danish oil.

Oil finish

Sanding before finishing In summary. Oil for furniture is one of the oldest finishing materials that protect wooden surfaces from damage and pollution. nine0003

Oil for furniture is one of the oldest finishing materials that protect wooden surfaces from damage and pollution. nine0003

Oils are of vegetable, animal, mineral and synthetic origin. Conditionally divided into drying, semi-drying, and not drying (not hardening). Drying, or rather hardening of the oil, occurs as a result of oxidation and polymerization. After curing, the oils are not washed away by water. Pure natural oils dry for a long time, create an extremely thin, not resistant film. Therefore, in its pure form, they are practically not used. Their properties are improved by various additives. Dryers, heat treatment, fragrances, dyes. nine0003

Furniture oil can easily repair minor damage to the lacquer coating during self-restoration of furniture. To do this, it is enough to clean the surface of dust and dirt, degrease with alcohol or a solvent, then apply a thin layer of oil. Rub with a brush or swab.

Oil to be applied ONLY on a homogeneous surface! If traces of varnish remain on the wood, preventing the penetration of oil into the wood, “non-oiled” light spots may form in these places.nine0009

Oil finishes are easier to apply than all other furniture finishes. They are prized for their soft sheen and sophisticated beauty. When finishing furniture, linseed, teak and so-called Danish oils are used. The first layer penetrates into the pores of the wood. After repeated overlays, it forms a transparent thin film, reacting with atmospheric oxygen. Teak oil and Danish oil are commercial names for furniture finishing compounds. They contain special ingredients that allow them to dry quickly. Linseed oil for furniture can be used without dilution, but more often it is combined with the same amount of turpentine. nine0003

When restoring antique furniture, in some cases, natural drying oil is used (linseed oil that has undergone heat treatment with the addition of desiccants). Drying oil dries faster than raw oil. Not three days, but only a day. Forms a film.

Linseed oil finish can be renewed. Periodically apply new layers, but no matter how many layers are applied, linseed oil furniture coatings are still not strong enough and do not resist moisture. Teak and Danish oils last longer and resist moisture. It is good to use oil for furniture from an array of valuable dark woods. Light rocks under oil darken unevenly. Oil-soaked veneer often peels off, and the oil film that forms between solid wood and veneer prevents the furniture from being restored. nine0003

Teak and Danish oils last longer and resist moisture. It is good to use oil for furniture from an array of valuable dark woods. Light rocks under oil darken unevenly. Oil-soaked veneer often peels off, and the oil film that forms between solid wood and veneer prevents the furniture from being restored. nine0003

Modern furniture oil is sold in specialized stores, in beautiful packaging and smells great, but we, in the responsible restoration of antique furniture, use only varnishes and polishes.

Best regards, Elena Zhilina.

Feedback form

By sending us a completed form with photos, as well as asking a question, you will receive a complete information about the item (what it is, material, age) the cost of work to restore it. Next, the restorer will come to the site, inspect it, determine the final price of the restoration. nine0003

The final price will not change. Departure is free.

Ask a question, evaluate furniture, calculate the cost of restorationHow to contact you? Email or phone.

If you have photos, attach (no more than 6 MB) If there are many photos, use the mail [email protected]

News from Elena Zhilina's Workshop

25.10.22 The workshop participates in the exhibition 48 Antique salon , held in Gostiny Dvor from 23 to 27 November.

05.08.22 From August 24 to 28, our workshop participates in the exhibition of vintage and retro cars Oldtimer , which will be held at Crocus Expo

07/01/22 Our workshop congratulates all restorers and lovers of antiques with "Restorer's Day" together we can preserve the memory of our ancestors for the bright future of our children

05/19/22 May 20 marks 30 years old of our workshop, which we carried out restoring furniture

Restoration of old furniture at home

New life for old things

Do you want to restore your wooden furniture, but don't know where to start? Follow these tips for details on the correct method of applying wax, ideas for finishing antique furniture, and a list of different ways to clean and restore antique furniture.

Do-it-yourself antique furniture restoration in a well-ventilated area and use a protective mask when sanding and varnishing furniture to protect yourself from dust and toxic paint or varnish fumes. nine0003

Simple ways to restore polished furniture

If your furniture has become scratched over time, you can restore the polish by wiping the old table or chest of drawers with a specialized furniture cleaner, or by using one of the popular ways to restore the shine of polished wood at home. However, before using any new product or method, be sure to test it on an inconspicuous area. It is also very important to clean with gloves and a mask, even if you use folk remedies, to protect the skin and respiratory tract,

-

Boil a piece of pure white wax in a small amount of beer until it dissolves completely, then rub the furniture well with this solution.

-

Minor scratches can be removed by rubbing a piece of walnut on the furniture.

-

Mix wine vinegar and olive oil 1:1 to make a polish-safe cleaner.

-

Polish the table with strong tea leaves - black tea will help restore the shine. nine0003

-

Spots left by wax drops can be removed by wiping with petrol.

-

Wipe the traces of hot dishes with a bag of thin cloth, in which pour salt, and then rub the treated area with sunflower oil.

These easy steps will help you restore polished furniture by hand, restore lost shine and deal with stains on polished furniture. Take care of your furniture regularly to maintain its appearance for a long time. nine0003

How to give old furniture a fresh look

Mini-survey

What distinguishing feature do you understand that the surface in the kitchen or bathroom is thoroughly disinfected?

On a pleasant smell from the surface of

0%

, shine on the surface of

0%

in a characteristic sound with a finger on the surface of

0%

for the absence of spots on the surface

0%

0 vote(s)

If measures to restore the shine no longer help and the antique table or chest of drawers has lost its noble appearance - do not despair and do not rush to call professionals. Here is a step-by-step guide to restoring old furniture at home.

Here is a step-by-step guide to restoring old furniture at home.

-

Remove all fittings and decorations from furniture.

-

Clean with a mild detergent - creamy cleaners like Cif are best. Read the instructions carefully and test the product on an inconspicuous area before use. nine0003

-

Remove old polish with a soft cloth soaked in solvent.

-

If there are deep scratches or chips on the surface, these should be treated with wood putty and the surface sanded with sandpaper.

-

Dry the treated surface before painting.

-

Use quick drying acrylic or alkyd paint to color your furniture. You may need to apply several layers to achieve the desired result. nine0003

-

Coat the interior item to be restored with a clear varnish.

This way you can restore the look of antique interior items at minimal cost and make changes to the familiar interior of your home, adding color to it.