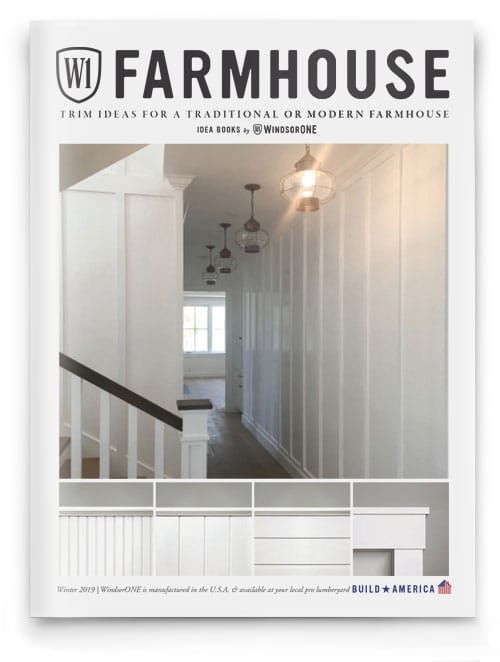

Trim ideas for house

The 15 Types of Trim You Need to Know for Your Next Remodel Project

Finding the right kind of trim is essential to completing any kind of remodeling project around the house. Familiarize yourself with the terminology and the available trim options to complete your project to make sure they fit with your home.

1 / 15

Family Handyman

Bare Wood

With a trim project you’re going to have to decide what types of trim you want to use. A good place to learn the types of trim is Lowe’s glossary. They are bare wood, primed wood, medium-density fiberboard, polystyrene and PVC trim. You should use bare wood if you want to stain it or have a natural wood look. The type of wood you can choose from usually ranges from poplar to pine to fir to oak to aspen.

2 / 15

Photo courtesy of Behr

Primed Wood

Primed wood trim is sometimes cheaper because you can use less expensive wood and use finger joints to join shorter lengths of trim. Some of the headaches of go away versus bare wood. Primed wood will cut the installation time since you won’t have to wait for the primer to dry. It’s easier to spot defects and nail holes on primed trim, so you can fill them before the final coats of paint. It’s even simpler to cope primed trim because the contrast between the raw wood and the painted surface gives you a crisp profile line to follow. So don’t buy raw wood if you’re going to paint.

3 / 15

Family Handyman

Medium-Density Fiberboard

Medium-density fiberboard is a popular option for trim because it’s typically the cheapest. It does come with its own set of issues, though. MDF won’t perform as well in wet, humid areas. MDF (medium-density fiberboard) is inexpensive and a great material for painted trim, but only if you’re installing it in a permanently dry place. Installing it near the floor or near windows where water or condensation sometimes collects is a recipe for disaster. The MDF will soak it up like a sponge, expand and shed paint in very short order. So avoid using MDF anywhere at risk for getting wet.

The MDF will soak it up like a sponge, expand and shed paint in very short order. So avoid using MDF anywhere at risk for getting wet.

4 / 15

Polystyrene

Polystyrene trim is made of rigid foam material and is a cheap, easy-to-work with option for trim, depending on your needs.

5 / 15

Family Handyman

Polyurethane

Polyurethane trim is an option that won’t see much deterioration because of its build. Polyurethane is typically ready to paint, cuts like wood and is lighter weight than wood. Working with polyurethane trim is much like working with wood—you cut it with standard saw blades, nail it by hand or with a gun and paint it just like wood. Home centers carry a small selection of polyurethane trim. You can find an endless variety of options by going online and searching for “polyurethane trim” (some products are listed as “urethane” rather than “polyurethane”).

6 / 15

Family Handyman

PVC Trim

PVC azek trim is ideal for exterior trim options because of how it holds up against sunlight and how it keeps paint. It cuts almost like wood and is a good alternative in areas that take on water. PVC trim runs about the same price as knot-free wood. PVC trim is emerging as an interior trim option as well.

7 / 15

Decks.com

Wood Composite

Wood composite trim is made up of wood fibers, phenolic resins and wax. They can be cut like wood and come factory primed. Wood composite trim is also another option for exterior trim to give the appearance of wood trim. It’ll save you time and money in the long run since it holds paint better and longer than even the best-quality exterior wood.

8 / 15

Family Handyman

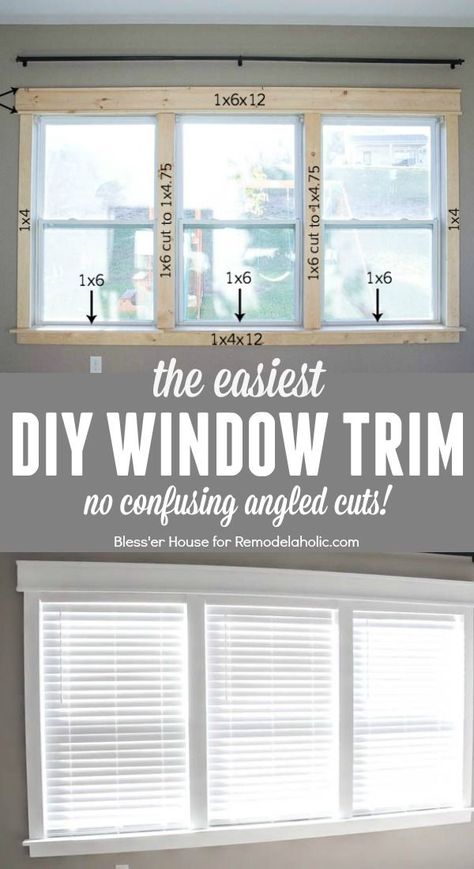

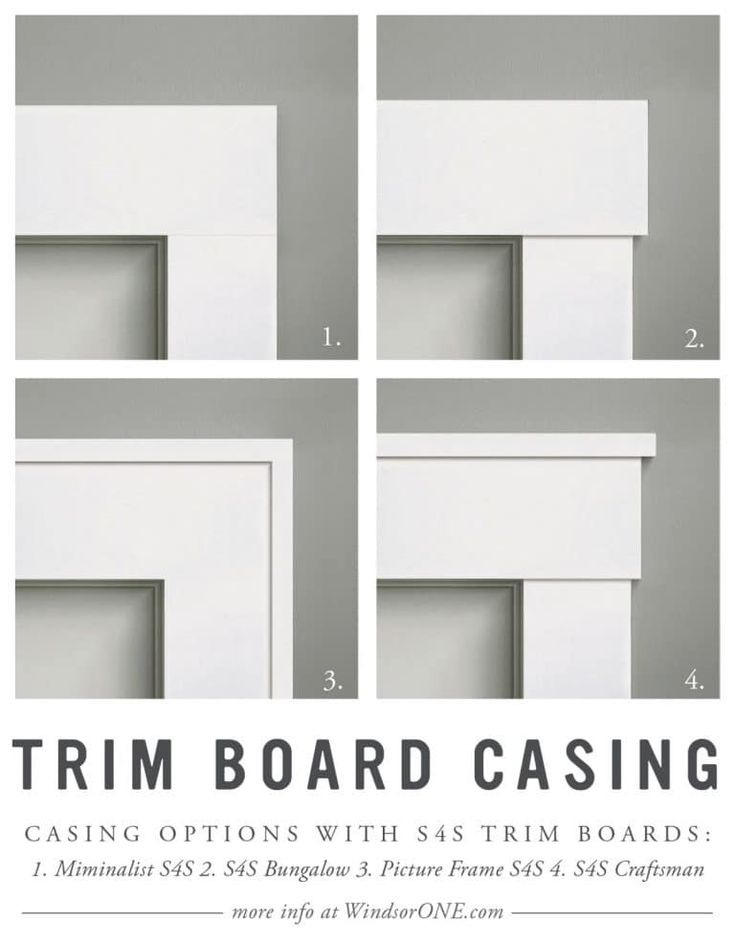

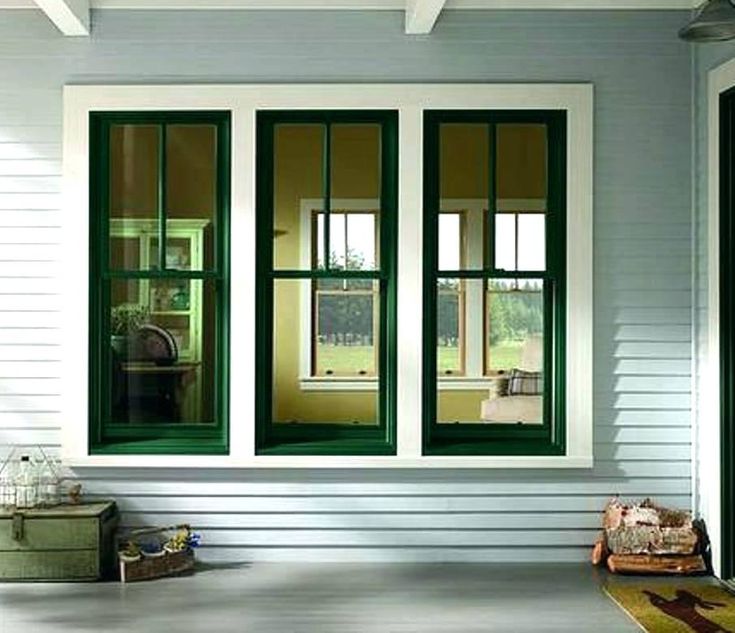

Area Specific Trim: Casing

Casing refers to the trim used around interior or exterior windows and doors. Casing is designed to cover the unfinished gap between walls and door or window frames. It usually spans two or three inches.

Casing is designed to cover the unfinished gap between walls and door or window frames. It usually spans two or three inches.

9 / 15

Family Handyman

Baseboards

Baseboards are trim placed on the bottom of walls where they join the floor. Baseboards, which are also called wall base molding, cover the joint between the wall and the floor and come in a variety of designs. From softwood to hardwood to vinyl, there’s a lot to wade through and it’ll have to match the other trim in the house.

10 / 15

Family Handyman

Crown Molding

Crown molding covers the corners between ceilings and walls. It comes in at a big angle and can be tricky to install. Crown molding is also known as cornice moldings. It’s not necessarily needed in all instances but it can add a decorative flair to a home.

11 / 15

Family Handyman

Chair Rail

Chair rail was originally meant to protect walls from furniture damage but these days it can also be decorative. Chair rail is a great way to dress up the dining room or other rooms. It can also be used to breakup wallpaper from paint or the use of two different paint colors.

Chair rail is a great way to dress up the dining room or other rooms. It can also be used to breakup wallpaper from paint or the use of two different paint colors.

12 / 15

Courtesy of Burlap and Blue

Picture Rail

A picture rail allows picture frames to hang from walls without having to nail holes in the wall and can be a perfect addition to an older home. It’s also a great idea for homeowners who might not have the ability to hang pictures on their wall.

13 / 15

Family Handyman

Wainscoting

Wainscoting is wood paneling against a wall, similar to a chair rail but there is a difference. Wainscoting is seen in foyers, staircases, master bathrooms and dining rooms. Wainscoting is panels that extend from the middle of a wall to the floor almost while chair rail is just a horizontal rail in the middle of a wall.

14 / 15

https://www.crazy-wonderful.com/

Wall Frame Molding

Wall frame molding is made to look like a picture frame but is typically larger. Wall frames are found in Georgian and neoclassical homes and typically in hallways, stairways, living rooms or dining rooms. The precise nature of working with trim can mean a time-consuming venture.

15 / 15

Family Handyman

Plate Rail

A plate rail is used as a platform to store a collection of items like jars or pottery and is another of the many types of trim options.

Originally Published: October 26, 2017

Types of Moldings - 10 Popular Wall Trim Styles to Know

Decorative Moldings

1/11

Moldings exist in myriad forms. Each is designed for a specific purpose—framing a door, for example, or providing a visual transition at the junction of walls and flooring. So many types of molding decorate our homes today, it's often difficult to distinguish them—and learn which types you should purchase for your home remodeling project. But here's the good news: You never again have to be confused between batten and baseboard. Scroll through to discover your molding style, once and for all!

So many types of molding decorate our homes today, it's often difficult to distinguish them—and learn which types you should purchase for your home remodeling project. But here's the good news: You never again have to be confused between batten and baseboard. Scroll through to discover your molding style, once and for all!

Related: 20 of the Best Pieces of Advice from Home Makeover Shows

istockphoto.com

Casing

2/11

Casing is designed to cover the unfinished gap between walls and door or window frames. Though different variations of door casing styles are readily found, the width of casing usually spans two or three inches.

Related: 18 Inviting Entryways We Love

istockphoto.com

Baseboard and Baseboard Styles

3/11

Used to trim walls where they join flooring, baseboards usually measure three to five inches. Baseboard styles are usually simple, and accented with a small piece of quarter-round (semi-circular) trim.

Related: 17 Times Shiplap Made the Room

istockphoto.com

Advertisement

Crown

4/11

This molding is the "crowning" architectural feature of a room, as it decorates the transition between walls and the ceiling. Crown moldings, also known as cornice moldings, typically boast intricate silhouettes—although many types of crown molding exist.

Related: 10 Ways to Reinvent Any Room with Crown Molding

istockphoto.com

Chair Rail

5/11

Chair railing is functional molding meant to protect walls from being damaged by furniture. Of course, it can also serve a purely decorative function, delineating two different types of wall coverings—paint and wallpaper, for instance.

Related: 15 Frugal Ways to Furnish Your Home at Home Depot

istockphoto.com

Picture Rail

6/11

Picture railing, like this one installed by A Beautiful Mess, allows artwork frames to be hung without nails having to be driven directly into the wall. Often combined with crown molding, this type of molding is one or two inches tall and appears seven to nine feet off the floor.

Often combined with crown molding, this type of molding is one or two inches tall and appears seven to nine feet off the floor.

Related: These 9 Forgotten Home Trends Are Suddenly Cool Again

abeautifulmess.com

Advertisement

Cove

7/11

Also known as coving, cove molding is plain, concave-shaped trim employed where walls and ceilings meet. It can also be used on stairs, at the meeting of risers and treads. In essence, cove may be considered a less ornate version of crown.

Related: 21 Clever Tricks to Make Your Home Look Bigger and Brighter

istockphoto.com

Dentil

8/11

An ornamental detail with a Classical pedigree, dentil molding consists of small, evenly spaced blocks in a repeating pattern. Incorporated into crown molding, dentils are frequently found in historic homes.

Related: 21 Totally Free Ways to Upgrade Your Home

istockphoto. com

com

Egg-and-Dart

9/11

Mostly seen together with crown or chair railing, egg-and-dart molding includes oval egg shapes (modeled after ancient Greek template ornament) alternating with V-like darts. Available on Home Depot; $18.72.

Related: 20 Best Ways to Spend $20 on Your Home

homedepot.com

Advertisement

Batten

10/11

Batten, also called board-and-batten, is a wall trim piece used to hide the joint between two pieces of paneling.

Related: 14 Easy DIY Living Room Updates Anyone Can Do in a Day

istockphoto.com

Bead, Pearl

11/11

Bead and pearl moldings are two different, though very similar, types of trim. Both feature a row of small, symmetrical spheres. Paired often with other designs—leaves, darts, or spindles—this variety of molding typically accompanies crown or chair railing.

Related: 10 Best Ways to Spend $10 at Target

istockphoto.com

Don't Miss!

If you have the money to hire a handyman for every household woe, go ahead. But if you want to hang on to your cash and exercise some self-sufficiency, check out these clever products that solve a million and one little problems around the house. Go now!

Facing finishing the facade of a private house: photos, options, ideas

Today there are quite a lot of types of finishing the facade of a house, and they all differ not only in terms of cost and decorative properties, but also in terms of durability and reliability. Consider those in which this combination is the most advantageous.

-

Brickwork in two or more colors

You can experiment with color. Combinations of contrasting colors are almost always a winning solution. The design of the facade looks especially aesthetically attractive, done in restrained black and white.

nine0003

nine0003 -

Combination of bricks of different textures

Combine not only colors, but also textures. For example, façade cladding with wild stone-like bricks will perfectly highlight elements such as fireplace chimneys and give the building a cozy feel.

-

Pattern brick

Facade design with facing brick, slightly different in shade and pattern, will visually lighten heavy and monumental structures. The minimalism of the form will be enriched with an interesting finish. nine0003

Facing brick is an option that combines a variety of textures, colors and shapes. It provides a wide field for experimentation in facade design thanks to these qualities. At the same time, it is durable (with proper installation it can last up to 200 years), frost-resistant and provides high tightness and thermal insulation.

Various types of bricks for finishing a private house provide an opportunity to combine the aesthetic the attractiveness of the facade without compromising its durability. This option involves spending not only on high-quality material, but also on installation. However, the result will definitely be worth it. since facing bricks, especially clinker bricks, deservedly have a reputation as one of the most wear-resistant facing materials. nine0003

Various types of bricks for finishing a private house provide an opportunity to combine the aesthetic the attractiveness of the facade without compromising its durability. This option involves spending not only on high-quality material, but also on installation. However, the result will definitely be worth it. since facing bricks, especially clinker bricks, deservedly have a reputation as one of the most wear-resistant facing materials. nine0003 -

No-frills plastering

Monochromatic light plaster in combination with warm dark colors of the functional details of the facade will look laconic and as presentable as possible.

Stucco is a simple and popular option. It provides a wide scope for imagination and is applied to facade cladding in a variety of architectural styles. Its cost can also vary greatly due to the characteristics of the composition: from the most affordable mineral to the rather expensive silicone.

However, they all have many useful characteristics. For example, the service life of even the most economical plaster starts from 14 years. The material, of course, also has disadvantages: high fire hazard and easy contamination in acrylic type. The structural diversity of plaster already makes it an excellent material for house facade decoration by itself. Other than that, it fits perfectly. with other types of cladding, refreshes the appearance of the building.

However, they all have many useful characteristics. For example, the service life of even the most economical plaster starts from 14 years. The material, of course, also has disadvantages: high fire hazard and easy contamination in acrylic type. The structural diversity of plaster already makes it an excellent material for house facade decoration by itself. Other than that, it fits perfectly. with other types of cladding, refreshes the appearance of the building. -

Material combination (brick, wood, plaster)

The right combination of plaster, brick and wood in the decoration of the facade will give it an interesting originality, you will want to consider it for a long time. The main thing is not to overdo it with the number of textures and colors. nine0003

-

Facing with Dagestan stone

Natural Dagestan stone is an environmentally friendly facing material, which also has thermal insulation that is superior to concrete and glass.

If you want to give the appearance of your home of nobility and solidity, then a light Dagestan stone will be an ideal option. Ease of processing and ease of cleaning from dirt make it an even more attractive basis for external cladding. Regardless of the size of the slabs and the chosen shade, the decor of Dagestan stone looks elegant and expensive. Particularly good are the elements of architectural neoclassicism made from it. nine0003

If you want to give the appearance of your home of nobility and solidity, then a light Dagestan stone will be an ideal option. Ease of processing and ease of cleaning from dirt make it an even more attractive basis for external cladding. Regardless of the size of the slabs and the chosen shade, the decor of Dagestan stone looks elegant and expensive. Particularly good are the elements of architectural neoclassicism made from it. nine0003 -

Historical façade decoration

Exterior decoration of the house, with due desire, can become a real work of art, and not just a functional detail of the building. For example, you can create a facade that sends its view to other eras of the art world that you like. It can be any style, but it is important to remember that with the help of specialists, it will be much easier to implement it. Here Art Deco design is presented, but your imagination can go much further in design finds.

nine0003

nine0003

There are a lot of nuances in the case of facing the facade of a private house. A lot will depend on the work performed: from the durability and safety of the building to your aesthetic Satisfaction with the appearance of your home. Therefore, regardless of your preferences and capabilities, it is better to entrust the work of decorating the facade to professionals. They will help you realize Your ideas are of the highest quality.

nine0002 №90№95

№36

Construction prices View All Projects

types of materials, installation features and properties

Exterior decoration of the house is one of the key stages of construction, which not only creates the appearance of the building, but also ensures its durability. We figure out how to decorate the facade of the house

We figure out how to decorate the facade of the house

Photo: shutterstock

The choice of finishing materials that are suitable for any type of facade is quite wide. Which one to prefer depends on the budget, the project of the house and personal preferences in decoration and design. We learned from experts what factors should be considered in the first place.

- What is a facade and its types

- Facade finishes and materials

- Plaster

- Wood

- Panels

- CSP and ALP

- Natural stone

- Brick

- Siding

- Porcelain stoneware

- Metal panels

- Liquid Stopper

What is a facade and its types

adv.rbc.ru

Facade - front part of the building. It can be made of different materials, most often brick, wood or concrete. According to the type of device and performance characteristics, facades are divided into two types: ventilated and non-ventilated. nine0003

nine0003

Non-ventilated façade: finishing material is applied directly to the front side of the load-bearing wall with maximum adhesion (adhesion). As a rule, such a facade requires preparation for finishing work.

Ventilated (hinged) facade: With such a system, a special ventilation gap between the wall and the cladding material is maintained during installation. This ensures the circulation of air, which moves inside, from the bottom up. Insulation can be laid in the space between the wall and the cladding. Ventilated facades usually do not require special preparation before finishing work and are suitable for almost any building. nine0003

Facade decoration and materials

The main purpose of house cladding, along with creating an aesthetic appearance, is to protect walls from moisture, temperature extremes and mechanical damage. Materials for exterior decoration differ in manufacturing technology, profiles, color, texture and fastening methods. Depending on the type of facade, decorative elements are mounted on walls or on a remote frame.

Depending on the type of facade, decorative elements are mounted on walls or on a remote frame.

Plaster

Plaster is a rough and finish mortar for interior and exterior applications. It is applied both directly to the walls and to a pre-fixed layer of insulation. For better adhesion, the surface is primed and a special reinforcing mesh is mounted. Walls can be plastered manually or mechanically. nine0003

Photo: shutterstock

This finish is suitable for facades made of brick, foam blocks, gas blocks or concrete. Some types of plasters are applied to wooden surfaces and chipboard. The plaster is produced in the form of a dry mixture, which is diluted in the required proportions with water, and as a ready-made solution (usually sold in buckets).

There are several types of plasters, which differ in the type of binder:

- Cement . Cement-based dry mix to be diluted with water.

nine0010

nine0010 - Mineral . Based on the same cement, but with the addition of lime, stone chips and colored clay.

- Acrylic - based on synthetic resins.

- Silicate - using water glass.

- Silicone . The main binder is natural silicone.

Thanks to additional plaster fillers, various patterns and textures can be created on the facade. To do this, manufacturers add quartz, marble chips, small gravel or mica to the mass. Depending on the type and fraction, Venetian plaster, “bark beetle”, “fur coat”, “lamb” or travertine imitation are obtained. nine0003

To improve the quality and durability of the plaster, antifungal or moisture-repellent modifiers, plasticizers and dyes may be included in its composition.

Advantages:

- if the technology is followed, the coating can last up to 30 years;

- steam capacity: the walls will "breathe";

- good heat and sound insulation properties.

Cons:

- work is carried out only in the warm season, avoid direct sunlight in hot weather, strong wind and rain; nine0010

- plaster should be protected from rapid drying and freezing temperatures;

- in case of violation of technology, cracks, peeling, fungus and mold can start.

Denis Izhutov , Knauf product manager:

— The advantage of a plaster facade is ease of installation. The service life depends on the correct application, the class of plaster and other factors. Repair will depend on the nature of the damage. Both local and dismantling are possible. nine0003

A common version of plaster finishing and facade insulation is SFTK (facade heat-insulating composite system with external plaster layers) or “wet facade”. It consists of an adhesive layer, insulation (based on mineral wool or expanded polystyrene), plaster to create a protective reinforcing layer, primer, decorative plaster, as well as various fasteners and profiles. Not suitable for use on a SFTC tree. In case of damage to the system, both local repairs and major repairs with dismantling are possible. nine0003

Not suitable for use on a SFTC tree. In case of damage to the system, both local repairs and major repairs with dismantling are possible. nine0003

How to choose the right plaster for interior and exterior use

Wood

Belongs to the class of environmentally friendly materials. With proper care, such a facade will last for decades, protect the house from weathering and create additional insulation. Most often, pine, spruce, cedar, oak or larch are used for outdoor work. Boards can be of different lengths, shapes and differ in the type of fastening. The materials allow the use of horizontal or vertical masonry, herringbone or with gaps. nine0003

Photo: shutterstock

Clapboard . This is a cut board, the basis for which is a solid mass of wood, more often coniferous. Depending on the model and type (for example, euro), it differs in thickness, length and depth of fastening the thorn-groove. The lining is also divided according to the appearance of the profile. For example, a block house imitates a rounded timber, and an "American" has a beveled outer side.

The lining is also divided according to the appearance of the profile. For example, a block house imitates a rounded timber, and an "American" has a beveled outer side.

Planken . Board planed on four sides, straight or beveled. Planken is made from both traditional woods and exotic ones - teak, merbau or abashi. The main difference from lining is in the type of fastening and the absence of tongue-and-groove joints. Installation is often done in a hidden way, such a board can be placed on the facade both end-to-end and with gaps. nine0003

Thermowood (thermomodified wood) is obtained by high temperature and hot steam treatment. The moisture content of such material does not exceed 4%, it does not contain hemicellulose - a nutrient medium for fungi, such wood absorbs moisture less and is almost not subject to swelling.

Pros:

- improves the thermal insulation of the house;

- is resistant to mechanical damage;

- easy installation, it is possible to lay a layer of insulation.

nine0010

nine0010

Cons:

- needs regular maintenance;

- despite the existing fire and bioprotective impregnations, in the event of a violation of the technology, the tree is subject to decay and may catch fire;

- some types of wood are very expensive.

Sergey Baturin, an expert in the field of floor and wall coverings made of natural wood, head of Ekzofloor:

— Optimum quality wood species are those that grow in places with a harsh climate. A tree from the tropics also has strength and durability due to the presence of essential oils and antiseptics in the composition. If you choose ultra-resistant species - teak, kumaru, ipe or merbau - the facade will last up to 60 years, withstanding temperature extremes and humidity. nine0003

The most economical finish is heat-treated wood. The technology of thermal modification with water vapor is carried out at high temperatures, with which almost all moisture comes out of the wood. As a result, the tree during operation does not change its linear size, experiences temperature changes, and has a high fire resistance class.

The technology of thermal modification with water vapor is carried out at high temperatures, with which almost all moisture comes out of the wood. As a result, the tree during operation does not change its linear size, experiences temperature changes, and has a high fire resistance class.

Panels

A wide range of façade materials characterized by ease and speed of installation.

Sandwich panel house (Photo: shutterstock)

Such panels differ:

- according to the type of source material: cement, PVC, glass, wood and others;

- by the presence of a layer of insulation;

- appearance: stone, wood, brick, etc.

Here are some popular solutions.

Fiber cement panels . 90% composed of cement with the addition of cellulose or synthetic fibers that perform a reinforcing role. From the outside, fiber cement panels mimic various materials, such as brick or masonry. nine0003

90% composed of cement with the addition of cellulose or synthetic fibers that perform a reinforcing role. From the outside, fiber cement panels mimic various materials, such as brick or masonry. nine0003

Pros:

- strength and impact resistance;

- relatively light weight;

- tolerate temperature extremes well.

Cons:

- with prolonged contact with water, the cement in the composition begins to absorb moisture, which can lead to deformation.

Clinker panels (thermal panels) . Multi-layer material, consists of a decorative layer of clinker tiles and insulation - expanded polystyrene or polyurethane foam. Clinker panels are often used to insulate the basement. nine0003

Pros:

- high moisture resistance;

- fast installation, mounting on a special adhesive composition is possible;

- do not require special care.

Cons:

- need to prepare the facade and a flat surface;

- in case of violation of technology, condensate may accumulate in the resulting gaps.

Sandwich panels . Consist of several layers: metal, insulation, vapor barrier and another layer of metal, wood or OSB. This option is suitable not only for cladding, but also for the rapid construction of walls. nine0003

Advantages:

- fast mounting and dismounting;

- the possibility of construction at any time of the year;

- panel materials are not affected by fungi, mold.

Cons:

- vulnerability to mechanical damage;

- require good sealing.

HPL-panels (High Pressure Laminate) are produced under the influence of a special press on several layers of decorative paper and pulp impregnated with thermosetting resins. During processing, all layers of paper are impregnated with resins, which takes the form of a monolithic slab. To protect against external atmospheric factors and mechanical damage, the surface is coated with an acrylic composition. HPL boards are usually large and weigh quite a lot. nine0003

Nodira Isamiddinova, Head of Research & Development Department at AKFA Group:

— HPL panels are light, non-flammable and scratch resistant. The disadvantages include a device for special trimming for their installation and a relatively high cost. In addition, a large area of sheet panels creates a high wind load, which requires a strong attachment to the supporting subsystem.

Composite boards

Composite boards are another class of board materials used in construction and outdoor work, they serve as the basis for various finishing materials, are used in the installation of curtain walls and surface leveling. nine0003

nine0003

Photo: shutterstock

There are several types of such panels:

- Cement bonded particle board;

- ACL - asbestos-cement sheets;

- LSU - glass-magnesium sheet.

Depending on the type of board, it can be used for fire protection of wooden structures, wall and partition cladding, as a base for roofing, etc. They can be finished with finishes, such as plaster or facing clinker tiles. nine0003

Mikhail Bainov , Knauf Product Manager:

— Since these boards are heavy and dense, the duration of work with them increases: you need to cut the boards with a saw, pre-drill them for fixing. The materials have low frost resistance and do not allow creating a seamless surface. LSU, according to the latest European studies, when soaked becomes aggressive to the metal and releases unsafe substances. nine0003

An alternative option in curtain wall systems (HFS), as in the case of external cladding of frame walls, can be cement boards - aquapanels. They allow you to create seamless surfaces due to low linear expansions, they are easy to process and cut. Any finishing coatings that can be applied on a mineral base are mounted on such plates.

They allow you to create seamless surfaces due to low linear expansions, they are easy to process and cut. Any finishing coatings that can be applied on a mineral base are mounted on such plates.

Natural stone

One of the most spectacular, but also expensive ways of finishing the facade. Popular outdoor materials include slate, sandstone, quartzite, marble, and granite. nine0003

Photo: unsplash

Natural stone is easily combined with other finishing materials, and thanks to different types of masonry, it can be formed into a unique pattern.

Pros:

- environmentally friendly material;

- high resistance to sunlight, precipitation, temperature extremes and mold;

- will last a long time.

Cons:

- some types of stone are very expensive; nine0010

- the installation process is time consuming and highly skilled;

- natural stone cladding should be laid at the design stage of the facade and foundation.

Brick

Another classic façade finish. A wide range of facing bricks differs in manufacturing technology, shape and texture.

Photo: unsplash

Brick material :

- ceramic: made of clay, followed by a firing procedure; nine0010

- clinker: also made from clay, but of special refractory varieties, due to which it is considered more durable;

- hyper-pressed: based on cement-limestone mixture;

- silicate: the main materials in the composition are quartz sand and lime.

Brick shape : trapezoidal, wedge-shaped, rounded, rectangular, etc.

The texture of brick is changed by using different techniques:

- shotcrete : application of mineral chips on the front surface of the brick.

The size of the crumb can be different, sometimes a dye is added to it;

The size of the crumb can be different, sometimes a dye is added to it; - engobing : applying a thin layer of white or colored clay with mineral dyes to the brick surface;

- glazing : covering the brick surface with a special glaze that gives a glossy effect. May be different colors.

As a rule, brick facades are distinguished by their durability and high strength. The brick is resistant to UV radiation and temperature extremes, absorbs little moisture.

The most obvious disadvantage is the heavy weight of the final structure, which requires design preparation and the construction of a reinforced foundation. Also, for laying bricks, highly qualified builders are required.

Siding

Siding is the technology of cladding the facade with lath materials, which can be metal, cement, wood, vinyl or acrylic. nine0003

Photo: shutterstock

The last two types are most often found in the decoration of private houses.

- Vinyl siding . The main component is polyvinyl chloride (PVC). Additionally, manufacturers add dyes and various modifiers to the composition to improve the characteristics of the material. Depending on the purpose, three types of material are distinguished: basement, wall and soffit for roofing.

- Acrylic siding . A type of vinyl siding with a layer of acrylic applied to the surface, which improves the strength of the panels and protects them from fading. According to the method of fastening, shape and possible textures, acrylic siding is similar to vinyl siding.

Yana Gerasimova, head of the technical support service for the "Pitched roof and canvas" direction of TECHNONICOL:

- PVC siding does not need to be treated with bioprotective agents against rotting, mold and pests, in contrast to the finish of wooden lining, which in addition, it will have to be painted and updated every four to five years. The lifespan of vinyl siding is about 50 years. Such surfaces can be operated at temperatures from -50 to +50 °C. nine0003

The lifespan of vinyl siding is about 50 years. Such surfaces can be operated at temperatures from -50 to +50 °C. nine0003

Vinyl siding is not vandal resistant and will not withstand, for example, a hammer blow. But to accidental mechanical damage, like hitting the ball on the wall while playing football, it is quite resistant.

Porcelain tile

Porcelain tile is made from clay and quartz sand with the addition of other components and mineral dyes. The initial mixture is pressed under high pressure, and then sent for firing at temperatures above 1000 degrees.

Photo: shutterstock

Porcelain stoneware slabs come in different sizes and textures - polished, matt, sanded, with the effect of aging, etc. vision. Among the disadvantages is the impressive weight, which complicates the installation work. In addition, in the case of fastening to a curtain wall, additional reinforcement of the structure may be required. nine0003

Metal panels

Aluminum Composite Panels (ACP) - building facing composite material. The panels consist of two pre-painted aluminum sheets 180 /210/250 / 400 microns thick, between which there is a middle layer - a polymer composition based on polyolefins.

The panels consist of two pre-painted aluminum sheets 180 /210/250 / 400 microns thick, between which there is a middle layer - a polymer composition based on polyolefins.

Photo: shutterstock

House facade cladding panels are suitable not only for new buildings, but also for the finishing of old buildings, regardless of the material of the building. Used for facing buildings made of brick and concrete. nine0003

Nodira Isamiddinova, Head of Research & Developmet Department of AKFA Group:

— The advantages of such panels include ease of processing (allow you to create a variety of architectural forms), increased fire resistance, the ability to maintain the original appearance. Technical characteristics allow the ACP facade to withstand various natural and weather conditions.

Weak maintainability can be noted among the shortcomings. In particular, to repair the facade or replace one panel, it will be necessary to disassemble the entire cassette. Another disadvantage is the high cost per square meter of products. The average service life of a facade made of composite panels is 25 years. nine0003

Another disadvantage is the high cost per square meter of products. The average service life of a facade made of composite panels is 25 years. nine0003

Liquid stopper

Relatively new technology and still rare in private housing construction. The composition of the sprayed material includes oak bark chips and acrylic binders with a dye.

Photo: @Thermacork/Twitter

This material is produced in dry form, to start work it must be diluted with water and mixed thoroughly. Liquid cork is applied in several layers mechanized under pressure using a cartridge gun.

Pros:

- can be applied to any shape;

- high noise and heat insulation;

- resistance to fungus, mold.

Cons:

- can only be applied at a certain temperature and humidity, in calm weather;

- requires special equipment;

- if the technology is violated, the uneven layer, the formation of smudges, and the peeling of the material are possible.

Learn more