Tiling around bathtubs

DIY Tile Tub Surround That Will Save You Money

Tiling around a tub is much easier than you might think! See how we DIYed our own bathtub tile surround and saved a lot of money during this bathroom renovation and learn how to tile a bathtub surround yourself.

Do you know how much money we saved on the kids' bathroom renovation by DIYing the tile tub surround ourselves?

About seventeen hundred dollars!

Once I'd planned the design of this space we got a quote to see what we were up against. We were quoted $1,700 just for the labor to tile around the tub shower combo. - That wasn’t in our budget and we knew it was something we could do ourselves.

I’m so glad we took on the bathtub tiling because I’m pretty sure I paid more attention to the details that were important to me than anyone else would.

It took us two days, but if you do the math, those two days were absolutely worth our time.

This was the first time the hubs and I took on a tile job of this size and if we can do it, you can too.

Today I’m going to walk you through the steps and show you how to tile around a tub.

PinOnce we set the tub and had the plumbing all figured out we installed HardieBacker (cement board) around our tub in place of drywall because it won’t absorb water. It installs just like drywall, it’s just harder to cut since it is much more solid.

A few things to note before you start Tiling Around A Tub

- Double check to make sure your tub is level in all directions (you probably already did this during the tub install).

You must make sure that you have a moisture barrier before tiling.

Prep the walls of your tile tub surround

- Cement board is not waterproof and some water will penetrate it and reach your studs (which can mold) if you don’t have proper water proofing. There are a few ways to do this. One can be a vapor barrier installed behind the cement board or you can tape the seams of your cement board and use a paint on vapor barrier on top of your cement board before tiling.

The DIY Tile Guy goes over how to install cement board around a tub and other ways to waterproof before tiling the bathtub surround.

The DIY Tile Guy goes over how to install cement board around a tub and other ways to waterproof before tiling the bathtub surround.

Plan the placement of your tub surround tile

- Once you’ve prepped and are ready for wall tile, decide where you're going to start placing the tile.

- You will want to consider the size of your tile and the length of your space so that you don’t end up with a really thin tile on the sides. I started on the bottom closest to the top of the tub and at the wall since my measurements made it so that I would have about ½ of a tile at the other end of my row. This makes for a really nice look. Take the time to plan it out before you start.

How much tile do I need for a bathtub surround?

How much tile you'll need when tiling a bathtub depends on the dimensions of your space, whether the tile will go all the way to the ceiling or not, and the size of the wall tiles you decide to use.

If you have a basic tile design like a subway tile tub surround you will have an easier project because there won't be as many cuts. If you have a more intricate tile design for your tub surround walls, it will take a bit longer because there will be more measurements and cuts to be made.

If you have a more intricate tile design for your tub surround walls, it will take a bit longer because there will be more measurements and cuts to be made.

Either way, you should plan on adding about 10% to your tile order to allow for mistakes and cuts.

Enlist some help

This project will go a lot faster if you have 2 people. The hubs was the tile cutter and I placed the tiles. We rented a tile saw and set it up in the backyard. I applied mortar to the walls while he was cutting, which made things go faster.

Enlist the help of a licensed contractor if needed (see my hold harmless disclaimer).

Below is a list of the exact tools and materials that I used and worked well for me. I received the tile for this project from The Tile Shop and was pleasantly surprised how easy it was to select tile online which saved me a lot of time. I definitely recommend them.

Tools For Tiling A Tub Surround

- Two 5 gallon buckets for mixing mortar and grout

- Drill with a universal mixing paddle

- Two large sponges

- Large putty knife

- Grout float

- Trowel

- Level

- Marker

- Tile saw (we rented ours from Home Depot)

Supplies For Tile Around Tub Shower Combo

- Bath tub wall tile

- We used Imperial Brite White Matte 4×8 ceramic tile from The Tile Shop

- Imperial Brite White Matte 4×8 (single bullnose short side) ceramic tile

- Tile spacers (I used ⅛ inch spacers)

- Thin set mortar (we used white since we planned to do white grout)

- Tile and grout sealer– you will want one that doesn’t change the color or create shine.

- Sanded grout (You will want non-sanded if working with glass tiles)

How to Tile Tub Shower Walls

Once your surface is ready you are ready to start tiling your tile tub surround!

We mixed our mortar according to the instructions in a large 5 gallon bucket.

If you're tiling an alcove tub, start by tiling the back wall above the tub, then move on to tile the wall behind the shower, then the third wall.

Apply a nice coat of mortar to your wall using a putty knife.

As soon as you have a row or two of mortar, scrape the mortar with a trowel to create your ridges. (The size of trowel you use matters. Check this resource to learn more.)

Place your first tile onto the wall and press evenly while giving it a little bit of movement back and forth. Slide it into place and check to be sure it is level. Repeat these steps with each tile, using a spacer between each tile to ensure evenly spaced tiles.

On the bottom row, use a spacer on its side to create a space between the tile and the top of the bathtub.

When you get to the end of a row, hold a whole piece of tile up and mark where you will need your cut.

Once you know the size of that piece you will most likely be using that size for each row, starting with that one on your next row if you’re doing a modified subway pattern like we did here.

The size of your cut tile may change as you work your way up the wall if your walls aren’t plumb.

PinWhen we got to the top of the wall we had to cut each tile length wise to finish the wall. Don’t worry too much about the gap between the top tile and the ceiling. You’ll be filling it with grout and it will look nice and finished in the end.

PinTiling the shower wall

On the next wall we ran into a few things we had to figure out.

The first was creating a clean edge where the tile would stop. We drew a line on the wall using a level to ensure it was exactly straight up and down.

PinThen we used tiles that had a bullnose edge on the short side to create a clean edge.

On this wall we started each row at the line and worked back toward the corner.

When we got to a point where there were no tiles underneath to support the newly placed tiles above, we used a nail (see picture above) to give support until we could come back and work our way down the side of the tub.

PinWhen it came time to tile around the plumbing, we held our tile in place to get the height of the pipe and then to the side to get the distance we needed from the edge of the tile.

Then the hubs cut a square into the tile according to our marks.

And we set the tile.

PinWe followed this same process when going around the other plumbing fixtures. You will want a tight fit, but don’t worry too much if it looks ugly; your fixtures will cover up these cuts nicely.

PinPinLook at that! Who knew we could be so handy?

Calling all DIY decorators!!! I promise decorating doesn’t have to be so overwhelming and time consuming. In my free on-demand decorating class I’ll teach you 3 easy steps to decorate any room in your home. >> Get instant access here.

In my free on-demand decorating class I’ll teach you 3 easy steps to decorate any room in your home. >> Get instant access here.

How To Grout The Tiled Tub Surround

Before you grout, let your tile set for at least 24 hours, but follow the exact instructions given on the mortar that you used.

Before grouting, inspect the lines and remove any large pieces of mortar that seeped out during installation. Use a metal scraper or putty knife to scrape out any excess mortar, being careful not to damage your new tiles.

PinApply the grout to the tiled bathtub surround in an X pattern

Prepare your grout according to the instructions on the package and gather your grouting tools!

Apply a blob of grout to your float and smooth onto your tiles so that all your grout lines are covered.

I found that moving my float in an X pattern ensured that I had filled each grout line well and didn’t leave any gaps or air bubbles.

You will want to work in one area of about 3 feet by 3 feet at a time.

Once the grout lines are filled, go over the area again with your float, removing as much excess grout as possible from the surface of the tiles.

If you don’t remove all the grout from the surface of the tiles, don’t worry about it. You’ll be wiping it off soon.

PinWhen I grouted where the tub and tile meet, I used a piece of painters tape to protect the tub.

Then I grouted like normal and immediately lifted the tape out slowly.

I dipped my finger in a little bit of water and ran it along the grout line to create a seal and to smooth it out (much like you do when caulking).

PinRemove the excess grout from the tub tile

The instructions on your grout will tell you how long to wait before going over the surface with a damp sponge. It will be before the grout is full dry and cured.

Once you are ready, get a clean bucket of water and a large sponge and wipe the tiles to remove the grout on the surface of the tiles. Once your sponge is dirty, rinse it in your bucket and keep going.

Your grout lines get smoothed out during this step, so pay attention to smoothing out any blemishes because they will dry this way and be permanent.

PinThe next day you will need to wipe the foggy residue from the tiles clean with a wad of cheese cloth. Wear a mask during this part because it creates a lot of dust.

PinFinishing your tile tub surround

Once you have the finished surface cleaned up all of the dust, let your grout cure according to the instructions.

You will also want to caulk around your fixtures and along the top edge of the tub.

Once the grout is cured, seal the tile and grout using an appropriate sealer for your type of tile.

Our Tiled Bathtub Surround

A few days of hard work later (and even eating lunch in this bathtub), we have a beautiful new bathtub with a subway tile tub surround that is a far cry from the one piece yellowish plastic tub surround we started with and the hall bathroom renovation is officially complete!

PinSo, what do you think? Have you ever taken on a project this big?

A big THANK YOU to The Tile Shop for providing the tile for this project!

Frequently Asked Questions - DIY Tile A Tub Surround

How did you create the little soap/shampoo cut out?

We created this during the drywall step and used an insert to make sure it was waterproof since it has extra seams. This video shows the gist of how we did it.

This video shows the gist of how we did it.

How many 4×8 tiles did you use?

I don't recall; we have a standard size tub and did the tile all the way to the ceiling (8 foot ceilings.) For help estimating, you can google “tile calculator” and some great free ones pop up.

What was the cost of the project?

We did this bathroom for under $5K and that included cement boarding and waterproofing the tub area, a new tub, tile for tub surround and floor, new cabinets (IKEA kitchen cabinets), countertop, and plumbing fixtures.

Where do you get the blue plastic to cover the tub?

It was on the tub when we bought it and so we left it on till we were done!

Ready to create a home that feels like you without the overwhelm?

Inside my course, Style Your Way Home, I'll teach you my step-by-step approach to discovering your unique design style and how to incorporate all the styles you love into your own home design plan. Plus, you'll learn my simple 4 step process to to apply your decor plan to any room in your home so you can make quick and confident decisions and create a home that feels like YOU.

for a stylish, practical finish |

Tiling a bathtub has a whole host of benefits, especially if you have splash-happy children in residence. Often the bath itself is in sound condition but the tile is dated, stained and tired, or perhaps you’re just ready for a change.

Refreshing and grouting tile around the bathtub is an easy way to revamp your bathing space, without the cost of new sanitaryware or rerouting plumbing, and the latest bathroom tile ideas are seriously eye-catching and will demonstrate just what can be achieved with a little time and effort.

‘It’s often not a huge area, so you can afford to be creative with interesting tile layouts and bold designs,’ says Martin Winterburn, manager at Total Tiles .

Below, our step-by-step guide has advice from tile professionals to help you achieve perfect results when tiling a bathtub.

How to tile a bathtub

Whether you are installing new or revamping old tiles, tiling around a bathtub is an achievable project that can easily be managed in a weekend. As with tiling a wall, you need a shopping list, and this will be longer if you need to remove wall tiles first.

As with tiling a wall, you need a shopping list, and this will be longer if you need to remove wall tiles first.

You will need:

- Bucket and mixing stick

- Sponge

- Notched trowel

- Smooth trowel

- Spirit level

- Tile cutter

- Grout float

- Grout smoothing tool

- Caulk gun

- Drill with diamond-bit hole saw (if taps are wall-mounted) – this diamond bit set is the most highly rated on Amazon .

1. Prepare the surface

As with any tiling task, it’s essential to ensure the substrate (the surface you are tiling onto) is clean, flat and stable. As the tile is going to be in a high splash zone, you should also apply a thin layer of waterproof sealer over the walls using a roller, taping any edges or joints first.

‘This is because grout is not waterproof and you need to make sure that no water will get behind the tiles,’ explains Mike Head, director at Atlas Ceramics . ‘If water does get behind the tiles, it can cause many issues like shadowing. If you have a shower in this setting, we highly recommend fully tanking the desired area before you tile.’

If you have a shower in this setting, we highly recommend fully tanking the desired area before you tile.’

Tip: If you are installing a new bathtub, do make sure the joint between the bath and wall is sealed with silicone before you start tiling. Alternatively, pull out and refresh old silicone if you’re keeping the tub.

2. Mark out the start position

When tiling a bathtub, it is best to start in the center of the bath (lengthways) and work outwards in either direction. Use a tape measure to calculate how many tiles, including grout lines, it will take to get to reach the corners. You may need to adjust the center line if you are left with only a slither of tile where you meet the corners. Aim to end with a half tile at the corner if possible, then continue with a half tile on the adjacent wall.

Tiling height is a matter of personal preference, unless you have an overhead shower, in which case the tile should go right to the ceiling. ‘When marking out your tiles, don’t forget to leave at least a 1/16in gap between the bath rim and first row of tiles to allow for caulking to fill the space,’ adds George Chister, Senior Director of Installation Materials, Floor and Decor .

3. Trowel on the adhesive

Begin trowelling on a thin layer of adhesive at your starting point, taking care not to completely cover your guide lines. Check the adhesive packaging to find out how long you’ve got before it sets – usually around 20 minutes. Mix up adhesive in small batches so you are not racing against the clock.

Use a notched trowel to create lines in the adhesive; this will remove excess product to ensure an even surface across the tiles. Try not to overlap the ridge lines if possible.

4. Start laying tiles

Position your first tile on the starting point line and push it tight to the wall with a little wiggle. Use a spirit level to check it is straight before continuing outwards to the corners and then down to the bathtub and up towards the ceiling. Use tile spacers to ensure even gaps, or source self-spacing tiles, which are perfect for novice tilers.

Fit all the full tiles before you begin the fiddlier task of cutting tile. To measure tiles for cutting, hold a full tile in place and use a tile pen to mark where it overlaps the last full tile on the wall. Use a tile cutter to score and then cut along this line. Always position cut tiles with the raw edge tight into the corner or ceiling to conceal imperfections.

Use a tile cutter to score and then cut along this line. Always position cut tiles with the raw edge tight into the corner or ceiling to conceal imperfections.

5. Drill out any holes for pipes (optional)

If you have wall-mounted bath taps or showerheads to connect, you will need to drill the tile. Plan for this in your initial laying out, aiming for a whole tile where the plumbing protrudes.

If you don’t have a diamond-bit hole saw for your drill, you could position the pipe on a joint between two tiles and use tile nippers to ‘bite’ out a crescent shape in each one, creating a circular hole when united.

6. Grout and seal

Grouting tile around a bathtub is the same as any tiling project – simply use a grout float to fill the void and then a smoother to achieve a neat finish. As this is a high-splash zone, it’s more important than ever to make sure there are no air gaps or pin holes in the grout. Make sure the grout is flush to the tile to ensure no water rivulets linger in the gaps. Use a damp sponge to clean the tile once the grout has set.

Use a damp sponge to clean the tile once the grout has set.

Sealing the gap between the bath and tile is the final step and should only be completed once the tile and grout is completely dry. Use a caulk gun to get a smooth line; practice first as it takes a little trial and error to pump out the perfect amount when caulking a bathtub.

‘Silicone is a flexible product, so unlike grout, it will retain some flexibility after it cures and won’t crack should the bath flex,’ explains Harriet Goodacre, Tile Consultant at Topps Tiles . ‘Look out for a sealant that has mould protection built into the formula. You can also get colored sealants to match your grout color, which is a neat touch.’

Tip: Fill the bath halfway before sealing to help maintain a watertight seal when in use. Wait at least 24 hours after sealing before using the bath to allow sufficient time for it to cure.

How far up should you tile a bathtub?

Unlike when you're tiling a shower, you don't have to tile up to the ceiling when you are tiling a bathtub unless there's a shower attachment over the bath; in fact, your tile layout patterns and ideas might dictate not just how high but in what configuration you tile.

‘When tiling above a bath, traditionally you would tile from floor to ceiling – but this is down to you, and your personal style,’ says Harriet Goodacre, Tile Consultant at Topps Tiles. ‘An alternative option is to finish your laying pattern three quarters of the way up the wall, and then paint the rest of the wall and the ceiling in the same shade. This can make even a small bathroom feel tall and airy, while still making sure your walls are protected from water damage where necessary.’

If you don’t have a wall-mounted shower attachment on the bath, you can get away with a much lower tiled bathroom backsplash but do think about how you will finish the edges as they will be far more visible. A narrow shelf is a neat way to conceal raw tile edges. Also consider tile trim or border tiles.

Can you tile a bathtub?

Many inset baths with flat, stable bath panels on the front are suitable for tiling as well as the walls around them.

‘Tiling the bath panel can allow for more creative options in terms of design by either choosing different colored or patterned tiles to add interest or using the same tiles as above the bath for a seamless look,’ explains Martin Winterburn, Manager at Total Tiles.

‘Remember to consider the access panel should you ever need it – a magnetic access panel is a great choice as this can be tiled over, or a bespoke timber frame can be made for future accessibility,’ adds Martin. ‘If the bathroom receives little daylight, consider using the bath panel to brighten up the room through the use of lighter colored, polished tiles to help make the room feel more spacious and brighter.’

How to properly tile around a bathtub

04/16/2018

Ceramic tiling is the most common way to finish surfaces in the bathroom. The process of laying tiles around a bathtub is slightly different from laying tiles on the walls of a room, but tiling begins the same way for all surfaces - with measurements.

Measure the width and height of each wall, and then determine the area of each vertical wall. In accordance with the calculations, it is necessary to purchase the required number of tiles, which are purchased by square meters. It is recommended to add another five percent to the calculated number received, which are spent on possible tile defects, damage, etc. In addition, when buying a tile, it is always necessary to check the shade of the tiles. Usually such a shade is indicated on the packaging with a set of letters or numbers.

It is recommended to add another five percent to the calculated number received, which are spent on possible tile defects, damage, etc. In addition, when buying a tile, it is always necessary to check the shade of the tiles. Usually such a shade is indicated on the packaging with a set of letters or numbers.

In addition to the tiles themselves, special profiles are often used for wall decoration - tiles with rounded ends, designed for final wall decoration. To calculate the amount of required profile, you need to measure the height of the outer edge of the wall along the bathroom. When buying a profile, it is important to know that it is not bought by square meters, like tiles, but by running meters or pieces.

Choose a tile only after calculating the amount of material required for cladding, as well as taking into account the use of finishing profiles, decorative tiles, etc. By diluting a plain or plain tile with several patterned tiles (or tiles of a different shade), you can make the cladding original and expressive .

Preparing for laying

The first step in laying tiles is to prepare the room and surface for laying. The bath is usually protected with a film from possible damage. For reliability, the polymer film must be secured with adhesive tape in several places. Pipes and taps located in the room are recommended to be covered with cardboard tubes.

The next step is to prepare the base for laying. A good base for laying tiles is cement board, while plywood, on the contrary, is not a desirable base for laying tiles, since surfaces around the bathroom are always exposed to moisture. It is recommended to use cement boards if possible. For example, if a house is just being built, then the use of cement boards, which can be purchased in specialized stores, can be foreseen in advance.

These boards are available in various thicknesses and dimensions. The most common plates are 12 mm thick, which have dimensions of 0.9 x 1.5 m. If necessary, finished plates can be cut, for which it is convenient to use a saw. It is necessary to mark with a pencil on the surface of the plate in the place where the cut should be made. Then small cuts are made with a saw, along which the plate is broken into pieces.

It is necessary to mark with a pencil on the surface of the plate in the place where the cut should be made. Then small cuts are made with a saw, along which the plate is broken into pieces.

Tiles are to be bonded to a smooth board surface using mastic, while tiles are recommended to be bonded to a rough board surface when Portland cement or other mortar is used as a tile adhesive.

When installing cement boards, it is recommended to leave a distance of about three millimeters between the individual boards. To fix the plate, you should use special screws, which are recommended to be installed at a distance of 15 to 20 centimeters. It is important to understand that the cement slab will not serve as an additional reinforcement of the wall, but is only intended to be used as a base for laying ceramic tiles on it.

Fix the boards in such a way that they are immobile, weak fastening must not be allowed. Otherwise, the plates may break or crack. The formed joints between the plates before the surface cladding is glued with a special tape consisting of fiberglass, the reverse side of which has an adhesive layer. This tape can be purchased at hardware stores.

This tape can be purchased at hardware stores.

Ceramic tile laying technology

Before laying the tiles, it is recommended to apply one row of tiles along the walls without glue in order to select the best laying option. A properly tiled surface is laying tiles in such a way that cut tiles do not have to be laid at their joining points on adjacent walls. For example, if it turns out that at the end of a row it is necessary to lay a tile whose width is less than two and a half centimeters, then it is recommended to cut the first tile of the row by the same amount. So the tiling of the bathtub will look more attractive, and you won’t have to spend a large amount of tiles on cutting narrow strips.

Appropriate marks must be made on the surface of the base in order to know the location of the cut tiles. After that, vertical lines are applied on the wall, along which masonry will be carried out to obtain strictly vertical rows. To obtain vertical lines, a special device is used - a plumb line. A plumb line is a cord with a weight attached to the end. With it, it is also easy to set surface irregularities before starting the main work.

A plumb line is a cord with a weight attached to the end. With it, it is also easy to set surface irregularities before starting the main work.

Experts recommend laying tiles on a small area of the surface. To do this, it is necessary, using the rule, to draw lines with chalk on the surface of the wall, delimiting small areas of the surface. The height of such areas can be from 4 to 6 tiles. After that, you can start laying tiles, while checking the evenness all the time with a level and a rule.

If you find that the rows are uneven, it is easier to correct the defect in a small area of the surface. To do this, it is enough to lay subsequent tiles, reducing or increasing the gaps between the tiles.

Special mastics or mortar can be used as a tile adhesive. With the help of mastic, ceramic tiles are laid quickly and reliably. The cement composition is also often used, but difficulties often arise in its preparation. It is not so easy to prepare such a solution on your own, so it is necessary to clearly maintain the proportions of the components of the composition and mix it correctly.

Therefore, it is easier to work with mastic. Using a spatula, it is necessary to apply an adhesive on a small area of the surface and apply the tiles one by one in accordance with the marking of the surface. Each tile should be leveled, pressed a little, and if excess glue appears, remove its surfaces with a scraper or spatula. If the glue got into the gaps between the tiles, then it is recommended to remove it with a narrow plastic spatula or a small wooden stick. In order to prevent excess glue from setting on the surface of the tiles, it is recommended to immediately remove it from the surface with a sponge and warm water during work. After the next section of the tile is laid, the surface of the tiles can be washed with water, gently rubbing the tiles with a well-wrung sponge, trying not to move them.

After laying all the tiles on the surface of the substrate, it is necessary to wait about a day until the tiles are completely dry. After that, you can proceed to the final stages of laying.

Cutting ceramic tiles

In order to cut a piece of ceramic tiles, it is necessary to make markings with a pencil and tape measure before the adhesive is applied to it. After that, a piece of tile should be cut along the resulting line using a special tool. In order to cut off sections of tiles that will be laid around sewer and water pipes, it is recommended to use tile tongs. With this tool, it is necessary to bite off small pieces of tiles along the marked line until a piece of tile of the required shape and size is formed.

A tile cutter is usually used to cut straight pieces of tiles. Using such a tool, you can quickly and easily cut off the required piece of tile, while getting a smooth and beautiful edge of the tile. As in the case of using tongs, you first need to draw a line on the tile along which to make a cut. Using the tool is simple: having installed it along the marked line, you need to press on the handle and the tile will quickly split into the required pieces.

Grouting

Once the adhesive is completely dry, grouting can begin. For small joints, use a grout that does not include sand. It is also recommended to use a grout with latex or to add “latex milk” to a regular grout to improve the properties of the grout.

It is recommended not to dilute the "latex milk" to save money, as is often done. This can lead to a decrease in the elasticity of the grout. In addition, the latex additive increases the durability of the coating and makes the adhesion of the material to the surface stronger and more reliable. Accordingly, if the concentration of the additive is reduced, its properties will also decrease.

Once the additive has been well mixed with the grout according to the manufacturer's instructions as described in the product instructions for use, the mixture must be allowed to stand for a few minutes. It is also recommended to prepare such an amount of the composition that is required to complete the work at a time, i. e. it is not advisable to store the grout.

e. it is not advisable to store the grout.

Use a rubber trowel to apply the grout to the tile surface. In this case, the rubber trowel should be held at a slight angle to the surface, and its movements should be performed in a diagonal direction. So the grout better fills the gaps between the seams. The field of how well all the seams between the tiles are filled, it is necessary to proceed to the next stage of work - cleaning the surface. It is necessary to start cleaning from the same place from which the grouting began.

Cleaning a tile is an easy, albeit boring, process. It is necessary to clean the surface with ordinary warm water using a large sponge. In the process of cleaning the surface, the sponge must be well wrung out and the surface completely wiped, placing the sponge at an angle of 45 degrees to the tiled seams of the lined surface. It is not recommended to rub the tiles parallel to the seams, as a little grout can also be washed off.

To remove the plaque that usually remains on the tiles after washing, you can wipe the surface with a dry white cloth. This completes the tiling. After the surface has been treated with a grout and cleaned, it is recommended that the grout be treated with a sealant after approximately three weeks (at least). Prior to this, it is advisable not to use the bathroom or to exclude water from entering the tile joints.

This completes the tiling. After the surface has been treated with a grout and cleaned, it is recommended that the grout be treated with a sealant after approximately three weeks (at least). Prior to this, it is advisable not to use the bathroom or to exclude water from entering the tile joints.

It is also possible to fill the space between the bathtub and the wall, as well as around the pipe holes, with a special sealant. So, laying tiles around the bathtub is easy if you follow the sequence of the main steps and take into account the features of the process.

How to tile a bath with your own hands: from the screen to the cladding

Work with joints

Laying tiles in the bathroom involves working with external and internal corners. A professional tiler makes smooth joints without the use of plastic corners. As a rule, tile cuts are made at 45 ° for this. Beginners use a plastic corner. Two tiles are first inserted into it and only then can it be glued to the wall using tile adhesive.

Another option for designing a corner, when the joint is made using tiles mounted perpendicular to each other. But, in such cases, a tiled end will be visible from one of the viewing angles. As a rule, it is sealed with grout. This option is more accurate than with a plastic corner. But there is one minus - if both tiles with side trim come across in the outer corner, then the seam will still be rough.

https://youtube.com/watch?v=a9Nlb3-PnoE%3F

Screen fabrication

Different types of screens are used in the bathroom. Depending on the characteristics of the room and the required functions, brick, plasterboard, metal and aerated concrete models are used.

Bricklaying

When designing a brick structure, the following features must be taken into account:

- The material is installed on the edge with a bandage of ½ stone.

- For bathtubs with oval, asymmetric or semicircular shapes, it is customary to use traditional masonry.

- The cement-sand mixture is diluted in proportions 1:4. In order to increase plasticity, 1 tbsp is added to 10 liters of solution. l. detergent or liquid soap.

- Plaster the screen before tiling. The procedure is needed to mask visible surface defects.

- Leave 1-2 openings in the screen for the sanitary manhole.

- Plastering is carried out along beacons, on straight surfaces using a rule, and on radius surfaces - with a piece of plastic plinth or profile.

- The cladding of the edge implies processing the perimeter to the thickness of the tile, which is 2.5-3 cm.

When assembling the box to support the sides, it is necessary to adjust the height of the masonry.

Brick bath screen.

This is done according to the following instructions:

- Attach legs to the bowl and adjust in height with a tape measure.

- The plumbing structure is installed on a layer of cardboard near the brick screen.

- Adjust the legs of the bowl.

The advantages of brick structures include:

- No difficulties in self-assembly.

- Durability and maintainability of the coating.

- No need to frame or drill walls and floors.

However, the technology also has its downsides. The number and size of openings for communications are limited.

Gypsum board construction

The bath is lined with moisture-resistant series of gypsum boards, which are not afraid of high humidity.

Bath screen made of moisture resistant drywall.

The following nuances are taken into account during finishing work:

- The frame is assembled from a galvanized profile.

- Hatch fastening posts are made of double profile.

- The frame is fixed to the walls and the bottom floor slab.

- For cladding of radius or curved sections, the slab is soaked with a moistened cloth or cut from the side of the smaller bend.

- Folding shelves, panels and drawers are used as an alternative to conventional hatches.

Plasterboard screen is popular due to:

- Minimum load on floor slabs and walls.

- Easy to assemble partitions with complex configurations.

- High process technology.

- Possibility to build manholes with different dimensions.

In addition, the screen must be attached to the load-bearing elements of the apartment. At home, you will need to drill walls, partitions and floors in inconvenient places. With subsequent repairs, it is quite difficult to detach the tile from the sheet.

Aerated concrete blocks

To seal the bathtub with aerated concrete, it is necessary to evaluate the following features:

- The blocks are made protruding outwards in order to fix the shelf on the sides.

- If the finishing layer is flush with the edge, then the internal elements of the blocks are turned to fit the dimensions of the structure.

- The slabs are fixed both with cement mortar and mounting foam with increased adhesive properties.

- Manhole openings are best made in masonry with horizontal slabs.

The method is characterized by minimal investment and high speed of action. The surface becomes more even than when using brickwork, and it does not need to be additionally puttied.

Aerated concrete screen does not require additional preparation for laying tiles.

Metal base

For assembly, it is better to use a galvanized metal profile, which should be sheathed with extruded polystyrene foam.

Work is carried out according to the following instructions:

- First, the length of the tub is measured and a profile of suitable length is cut.

- The construction is incised every 3 cm.

- A profile is attached to the edge of the bathtub and fixed on one side with construction tape.

- To hold the formed structure, the perimeter of the bathtub is glued with adhesive tape.

- Further, the profile is detached from the sides and attached to the floor with dowels, shifted by the thickness of the finish.

- If tiling is planned, the thickness of the tile and the layer of filler are taken into account.

The finished frame can be tiled, hiding all seams and defects.

Budget option

If the tiles look completely hopeless, the best option for updating the walls in the bathroom may be to finish them with plastic panels. They are easily mounted on the surface, even an inexperienced owner can carry out these manipulations. So the question of how to replace the tiles disappears by itself. In addition, the panels are resistant to high humidity and adapted for permanent contact with water. With the help of this decorative material, you can renovate the bathroom, creating an unusual design in it, in just one day.

First of all, you will need the following tools and building materials:

- scissors and a hacksaw;

- SD and UD profiles;

- self-tapping screws 25 mm;

- perforator;

- screwdriver;

- silicone sealant.

https://youtube.com/watch?v=8K5yelMXpvY

Work should begin with treating the walls with a primer antiseptic, marking and installing profiles, then work is underway on laying electrical wiring and other necessary communications. After that, wall panels should be attached to the profile. If the wall surface is even and smooth, the panels can be attached directly to it using a waterproof adhesive. Joints should be carefully treated with silicone sealant.

Sources

- staruyu-plitku-na-kuhne-i-v-vannoj.html

- https://stroy-podskazka.ru/nastennye-pokrytiya/plitka/obnovit/

- https://proffstroygroup.

ru/vannaya/kak-preobrazit-vannuyu -komnatu.html

- https://vseovannoi.ru/remont/kak-obnovit-staruyu-kafelnuyu-plitku-v-vannoi.html

- https://gs16.ru/vannaya-komnata/kak-izmenit-cvet -kafelnoj-tiles.html

Step-by-step instructions

There are a number of steps involved in tiling a bathtub.

To do this, it is worth doing the following:

To begin with, an adhesive composition is prepared, which is designed specifically for tiles. On sale it can be found in powder form. After that, it is worth diluting this mass with water, which has a room temperature indicator. The proportions are indicated on the packaging

It is for this reason that special attention should be paid to the package. Letters must not be erased

If the instructions are not legible, it is better to buy another package or ask the seller for a recommendation.

Gently apply the prepared adhesive to the screen surface. To properly lay it, you need to perform all the steps strictly according to the markup. It is better to work gradually, dividing the entire perimeter into parts of a certain size. The adhesive composition on the surface is leveled with a specially designed spatula with teeth.

Tiles are to be placed on the prepared area. In the case when it is clear that it is installed correctly, you can press it down a little. Further facing is carried out in the same sequence.

Tile adhesive should dry well for several days. Only after this is the grouting done. The procedure is carried out for greater tightness of the surface. If there is a desire to even more carefully close the gaps that could be formed during the performance of work, additional processing can be done with silicone sealant. It goes on sale in bottles that are convenient for finishing work.

In addition, exterior finish will help to remove communication systems located under the plumbing item from the human eye.

Criteria for choosing tiles

Since the bathroom is a room with high humidity, traditional types of tiles based on gypsum or hygroscopic rocks cannot be purchased for finishing work. It is better to purchase samples with increased resistance to mechanical stress, made of porcelain stoneware or natural stone.

Depending on the type of texture, tiles are divided into the following groups:

- Glossy. It has a smooth surface with a characteristic sheen.

- Matt. It has no shine and stands out with a muted color.

- Embossed. Suitable for the implementation of interesting design ideas, because. has an unusual structure.

Also, when choosing a tile, it is necessary to determine its shape. The following material configurations are available for sale:

- Square.

- Rectangle.

- Mosaic.

Example of a bathtub with mosaic tiles.

Preparing the bathroom tile mix

A little more than half of the container is poured into the already prepared container for the mortar, dry adhesives are poured into it in small portions and at the same time it is necessary to constantly mix with a mixer. After that, the solution should turn out to be a thick mass, such that it does not slip off the surface of the tile, but at the same time the mass should be very easily stretched over the tile.

preparing the masonry mix

When the mortar is ready, you can start laying tiles, starting from the bottom row and so on to the very top. During the laying process, care must be taken to ensure that the tile is laid evenly, it is necessary to check its level. Between the tiles there should be a gap uniform on all sides, which is done using special crosses for this (see photo). This gap helps prevent cracking of the tiles during thermal expansion.

Once the first row has been laid out, install the planks on both sides and check the level. A thread is pulled along the slats one row higher, which will significantly save time when laying and checking the level. In the case when the width of the wall does not match the width of a multiple tile, it is better to lay the pieces in a corner - this is less noticeable and not striking.

After finishing the walls with tiles, you need to lay the tiles on the floor, where the same principle of work is done as on the walls. However, you need to start from the far wall and head towards the doors. Then, after finishing work, the tile dries up and then you need to clean the surface of the tile from the remnants of glue and grout all the seams. Another exclusive option for bathroom design is tiling an acrylic bathtub. In order to know how to tile an acrylic bathtub, you can view the necessary information on the Internet, because it all depends on what shape the bathroom is.

grouting tiles

The most important thing here is to follow the basic laying rules and everything will turn out in excellent condition, where all requirements and wishes are taken into account.

Where to start

Good bathroom tiling depends on the correct tiling of all surfaces, including the ceiling. Tiled masonry of each of them has its own characteristics:

- walls - facing ceramic tiles are laid first on the floor, then on the walls. Facing the width of the wall should always start from the far corner relative to the entrance to the room. Thus, a base surface is created for further cladding. It must be remembered that the wall with the doorway is laid out last, then a strip is formed above the door. This will avoid numerous pruning in prominent areas of the walls. In height, laying wall tiles starts from the floor level or the edge of the bath, if it is already installed. When laying relative to the level of the bath, a rail is attached around the entire perimeter of the room, at the level of which the first row of tiles will be laid;

- floor - marking for laying tiles on the floor starts from the most noticeable corner and continues along the entire perimeter of the room;

- ceiling - when laying ceiling tiles, you can start from the center or from the edge along the marked line.

From the corner of the floor

From the corner of the wall

From the center of the wall

From the center of the floor room is the best option. The tile is moisture resistant, durable, easy to clean. In addition, the widest range will allow tiling bathroom tiles in accordance with any idea or design idea. It is not difficult to lay walls and floors with ceramic tiles with your own hands, the main thing at the same time is to acquire high-quality material so that it can easily withstand temperature extremes, high levels of humidity, and exposure to steam. And then the renovation in the bathroom will delight the owners for a long time.

Tools and materials

When choosing a bathroom cladding material, consider the following characteristics:

- technical parameters - strength, abrasion resistance, surface smoothness or porosity, chemical resistance. So, floor ceramic tiles for the bathroom should be distinguished by high wear resistance and a non-smooth surface;

- aesthetic parameters - color, ornament, compliance with the style decision of the room being designed;

- size and correct geometric shape.

Ceramic tiles are of various types, depending on the manufacturing method:

- bicottura are glazed ceramic tiles for interior wall cladding, their surface is double fired. Also with double firing there is a metlakh tile made from quarry clay. Not suitable for flooring. Glazed ceramic tiles for interior wall cladding are very durable, but their smooth surface is not suitable for laying on the floor. The exception is embossed tile glaze;

- monocottura - single-fired tiles. Durable, suitable for flooring;

- the most durable clinker tile, usually used for laying on the floor, resembles a brick in its appearance;

- mosaic - small tiles glued on mesh;

- porcelain stoneware imitating natural stone;

- glass and mirror tiles for walls and ceilings. It is subject to mechanical stress, so you can not lay the floor with it.

In addition to tiles, you will need the following materials:

- tile adhesive;

- primer, which must be with antifungal additives;

- grout;

- spacers (crosses) to regulate the thickness of the joints between tiles;

- silicone sealant;

- bathtub sealing tape;

- masking tape.

Do not forget that all materials used for ceramic tiling must be moisture resistant. From the tools you will need devices for applying and mixing the solution: a rubber or notched trowel for grouting, a container for primer and glue. Cutting tiles is carried out with a tile cutter, grinder or ordinary glass cutter, depending on the thickness and strength of the tile. In order to grind the edges of the tiles, you will need sandpaper. A rubber mallet is needed for tapping the material, its snug fit to the glue base. Also, you can’t do without a building level, a wooden slat to support the bottom row of tiles, as well as bricks, if necessary, to lay the screen space under the bathroom.

Ways of laying tiles in the bathroom

A novice tiler or anyone who first encounters ceramic tiles is unlikely to know many ways to lay tiles. Most likely, his knowledge is limited to laying in even rows, cutting off the last tile in a row if it does not fit. But there are many more ways than you can imagine.

- Direct masonry, which was mentioned earlier, is a way to save both your strength and resources. It is on this method of laying that the least tiles are spent. The first tile is laid from the corner of the longest wall. Further from this tile, horizontal and vertical rows diverge. It is worth monitoring the space between the tiles, and otherwise navigate by level;

- Another way is diagonal laying. It is no less common than the first, but is more complex. The name speaks for itself. Using this method, you can visually expand the space in the room and hide minor surface defects;

- Checkerboard is one of the most interesting ways of laying tiles. This method is applicable for multi-colored tiles (2 colors). The main task is to maintain the evenness of tiles of different colors in a row. So that the work is not burdened by the constant adjustment of the tiles along the edges, it is worthwhile to calculate in advance what size tiles will fit perfectly. On the wall, even placement of tiles can be achieved by changing the width of the joints;

- The more difficult method is offset laying.

This method is very time-consuming, requiring the utmost concentration and perseverance. The tile must look good when offset, and finding the optimal offset length is not easy;

- The most difficult way to lay tiles is mosaic. This option is not for beginners, it is better to entrust it to professionals.

The chosen method of laying also determines how much material to purchase, how much effort it takes to install tiles on your own, and how much the bathroom will change visually.

Installing on walls

Before laying tiles around the bathtub, prepare the room and all surfaces for installation. The bath, if it is not planned to be changed, should be covered with plastic wrap, and all pipes, tubes and taps should be wrapped with thick paper or cardboard. Clean the walls of old tiles, plaster and paint. Laying tiles is easier and more reliable on concrete walls.

For a more reliable adhesion of the adhesive to the wall surface, it is necessary to carefully primer. Use a special primer for rooms with high humidity.

Adhesive sold at a hardware store. It must be prepared strictly following the attached instructions. However, experienced tilers recommend "Ceresit 17" glue - mixed with cement in a ratio of 3: 1. This composition is proposed as optimal, because. clean “Ceresit 17″” - attaches too hard and tiles can break

It is important to stir the adhesive to the consistency of thick sour cream. For mixing it is worth using a drill with a special nozzle

How to properly tile a bathtub: a detailed plan

Mainly the height, the width of the walls can rarely match the multiple dimensions of the tile, which will then need to be cut. Actually, for this, it is necessary to draw up a bathroom plan, where you can see in which places the edged tiles will be the least noticeable. Also, such an accurate and correct plan allows you to make the correct calculation, which will provide an opportunity to significantly reduce the number of cuts. After the plan has been drawn up, you can calculate the amount of the entire tiled product you need.

Experts recommend - for a more efficient calculation, you need to count not in square meters, but in the required number of the tile itself, in pieces.

After that, you can go to the store and buy the selected tile option, but you also need to purchase tile adhesives. In the event that the repair will be done by a professional worker, he will tell you what kind and how much glue is needed for the work. However, if you yourself want to renovate the bathroom, then here it would be an excellent solution to use the advice of the seller in the store, who can provide the necessary information for a certain choice of this mixture.

What kind of bathtub can be tiled, the photo of which is presented below, clear step-by-step points are indicated will be used later

After that, it is necessary to dismantle all the old tiles that cover the walls and floor of the bathroom. The most effective method is to use a rotary hammer with the appropriate accessories that are needed to work safely with the equipment. During operation, some places will fall off in whole pieces, but this is not scary, because the old finish must be removed.

dismantling the old tiles in the bathroom

When all the old tiles have been removed, the next step can be taken - this is the alignment of the walls and for this you need to use a square, a plumb line and a water level, which will allow you to build a completely flat surface of the walls. Using a plumb line, you can determine what deviations the walls have from the vertical, and a square allows you to measure angles that should have 90 °. In the event that the walls in the bathroom are uneven, then it must be leveled - plastered. To do this, you need plaster beacons, a solution for fixing beacons, dishes for mixing the mixture, a puncher with a mixer nozzle, a flat board or profile, a ladle for plaster and a spatula.

After the process of leveling the walls and floor with plaster, you can start tiling the bathroom. In order to know how to tile a bathtub, the video will show all the necessary aspects of this work.

Steps, boxes and podiums

With the size of the combined bathroom from 9 sq. m, bathroom from 6 sq. m, steps, podiums can be attached to the plumbing, horizontally oriented boxes with water pipes, sewers, going in transit to the kitchen or connecting the bath to the risers, can fit.

Steps are used to improve user comfort, making it easier for older people and children to step over the side of the tub. Usually enough one or two steps from the floor level.

One step for easy entry into the sanitary bowl.

Either the level of the top step of the structure reaches the edge of the bowl. This option is only suitable for large spacious rooms.

Bath operation in pool mode.

In this case, lining the structures near the sanitary ware should be done in the same way as lining the stairs. The width of the horizontal duct must be less than that of the ceramic cladding to ensure that the vertical tile joints match.

The width of the box is smaller than the size of the tile.

The bowl of the sanitary ware can be partially integrated into the podium, as in the photo below.

Half-integrated bathtub.

In any case, knowledge of the standard schemes for laying out tiles on walls / floors will allow you to ensure an acceptable quality of interiors when finishing with your own hands.

The need to make a screen under the bath

Screens under the bath are intended for both aesthetic and practical purposes. They are necessary to create a beautiful and functional niche in which you can store various little things and useful things.

Under-bath screen option that solves the problem of storing bath accessories.

Sliding design allows you to quickly fix any plumbing failure, check the drain siphon or hide unused inventory.

Video tutorial on tiling a bathroom ↑

However, it will be much easier to understand how to tile a bath if you turn to specialists. Designers will develop a worthy project, and craftsmen will put ideas into practice.

In addition, any tiling work, even in a limited area, is difficult for an inexperienced repairman. Accuracy of calculations, ensuring the stability and safety of the frame, laying tiles - all these are quite complex processes. Cosmetic repairs, not to mention major ones, are always an update. I would like the bathroom to finally take on a perfect look and become a place of complete relaxation, detachment from the hustle and bustle. Such an attitude should not be overshadowed by minor imperfections or flaws. Moreover, professionals are always ready to help and take responsibility for a quality result.

Instructions for tiling a bathtub

Tiled bathtub

Currently, ready-made bathtub screens of various colors and designs can be found on sale, but our instructions will consider the independent production of such a bathroom screen from tiles.

The main steps and rules for laying tiles in the bathroom to cover the bathtub:

- When choosing the material for finishing the bathroom, you should consult the seller, because a beautiful tile in the bathroom must also have other important characteristics that allow it to be used in a room with high humidity.

Thin glazed ceramic tiles are perfect for vertical surfaces, but for joints it is desirable to use larger tiles to reduce the number of joints between tiles. -

The frame of such a bathtub screen can be made of a variety of materials, such as brick, gypsum blocks, foam blocks, etc.

The simplest in terms of manufacturing and optimal is the plasterboard construction, which is not only easy to assemble, but also quite simply dismantled if necessary, unlike brickwork.

-

First of all, you need a ceiling guide PP27x28 for the perimeter. On the floor and on the walls, the future location of the guide is marked, taking into account the thickness of the tile and drywall, so that after gluing the tile, it is slightly recessed under the edge of the bathtub and does not protrude.

Use a spirit level to draw vertical lines on the walls that connect on the floor. Along the side of the bathroom, measure the distance between the walls and vertical segments.

A blank is made from the guide, for this the edges of the profile are cut and bent so that the vertical segments are at the edges, and in the center is the distance between the walls (usually it turns out approximately 530-1500-530).

The resulting U-shaped structure is attached to the walls with dowel nails or self-tapping screws.

-

The track is attached to the floor, after which the vertical posts are installed, giving the structure additional rigidity.

-

When making a frame for the screen, it is imperative to leave a revision, that is, a removable part that allows, if necessary, access to the pipes laid under the bathroom. In our case, this revision is located on the left.

In addition, a footwell can be fitted at the bottom of the frame, allowing you to stand next to the tub more comfortably.

-

The rigidity of the screen can be further increased by lubricating the upper guide to the cast iron tub body with tile adhesive or rotband.

- Next, cut one or more drywall sheets to the required dimensions. The sheets are installed on the frame so that their joints fall on the rails and are securely attached to the rails with self-tapping screws.

For the bathroom, moisture-resistant drywall, usually green, must be used. Under the revision, a piece of drywall of the desired shape is cut out, which is not screwed on, but inserted tightly.

Cladding

-

The resulting structure is tiled, following the order of tiling in the bathroom. Gluing tiles to drywall is best done with liquid nails.

If necessary, cutting tiles can be done with a roller tile cutter.

-

Next, the joints between the tiles are grouted, after which the tiling of the bath is completed.

If desired, a special niche for legs and various accessories, such as various basins, etc., can be equipped in the bath tile screen. This hole also plays the role of additional ventilation of the space under the bath.

Learn more

- When should grass seed be planted

- Can you plant tulips in the spring

- What can you plant in may

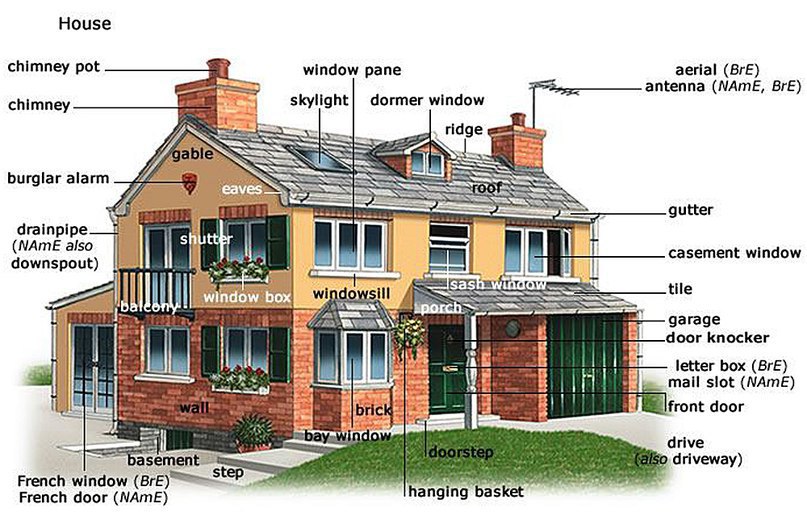

- House theme colours

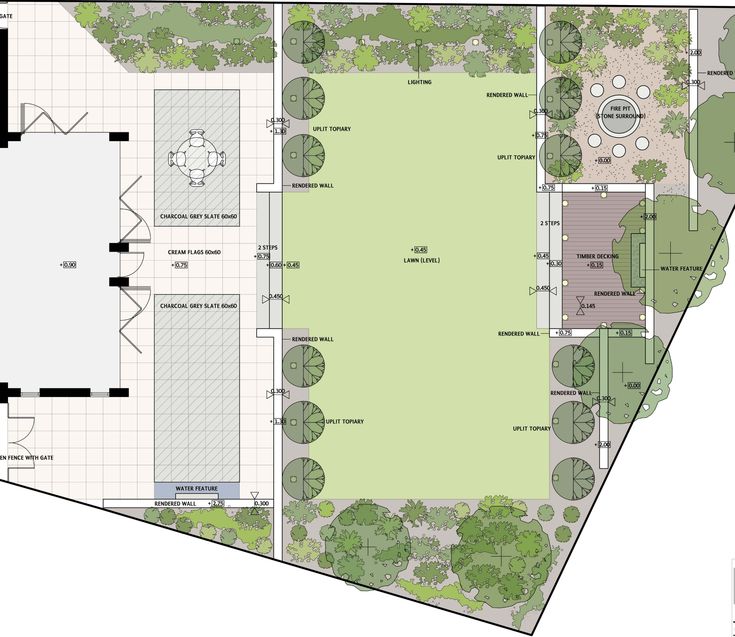

- Greek garden design ideas

- Monochromatic scheme interior design

- English garden design layout

- Dyson ball animal 2 origin upright vacuum cleaner reviews

- How to add a sliding glass door

- Wreaths on staircases

- Evergreen trees for pots