Installation prices for hardwood floors

How Much Does Hardwood Flooring Cost? (2022 Guide)

Hardwood flooring is both durable and sophisticated. Read on to learn how much it costs to install.

Reviews by This Old House Reviews Team 08/08/2022 1:00 pm

In This Guide: Average Costs | Cost Factors | Types of Hardwood Flooring | Pros and Cons | DIY vs. Professional Installation | How To Save | How To Install | How To Hire a Pro | Conclusion | FAQs

Hardwood is a popular flooring material that can increase the value of your home. While it’s extremely durable and sophisticated, it comes with high up-front installation costs. Below, we outline the cost to install several different types of hardwood floors, plus list the pros and cons of this type of flooring.

Average Hardwood Flooring Cost

The average cost of installing hardwood floors is $3–$10 per square foot for materials and $3–$8 per square foot for labor, totaling $6–$18 per square foot. A single 200-square-foot room might cost $1,200–$3,600, while a 2,000-square-foot house could cost $12,000–$36,000. Wood quality influences price, with high-end flooring costing up to $25 per square foot. Square footage is the greatest determinant of price. Still, the following factors also come into play:

- Type of flooring: Solid hardwood is traditional, but you can also opt for engineered hardwood or parquet.

- Tree species: The more durable and less common the wood type, the more it costs.

- Thickness: Thicker boards can withstand more refinishing and therefore cost more.

- Grade: High-quality boards cost more than low-grade ones.

- Cut/grain: The way the boards are cut from the tree can mean more or less labor and waste.

Hardwood Flooring Cost by Type of Hardwood

Hardwood flooring cost varies based on the price of the material and the labor involved in installation. Traditional solid hardwood flooring consists of real wood planks cut from trees, which are installed end-to-end. Engineered wood flooring, which has a real wood veneer attached to a plywood base, may be slightly less expensive. Parquet flooring uses smaller pieces of real wood to create geometric designs, such as a herringbone pattern, making it the most expensive to install. Prefabricated, parquet-like tiles are a lower-cost alternative that give the appearance of parquet but are easier to install.

Traditional solid hardwood flooring consists of real wood planks cut from trees, which are installed end-to-end. Engineered wood flooring, which has a real wood veneer attached to a plywood base, may be slightly less expensive. Parquet flooring uses smaller pieces of real wood to create geometric designs, such as a herringbone pattern, making it the most expensive to install. Prefabricated, parquet-like tiles are a lower-cost alternative that give the appearance of parquet but are easier to install.

| Type | Material Costs | Installation Costs | Total Cost per Sq. Ft. |

|---|---|---|---|

| Solid hardwood | $2–$20 | $3–$8 | $5–$28 |

| Engineered wood | $3–$14 | $3–$9 | $6–$23 |

| True parquet | $3–$18 | $10–$22 | $13–$40 |

| Parquet-style tiles | $3–$5 | $7–$10 | $10–$16 |

Hardwood Flooring Cost by Tree Species

Tree species greatly influences the cost of traditional hardwood. There are several types of wood to choose from that vary in appearance and performance. Some tree species are more durable than others or better suited to certain types of climates. Generally, the harder and more durable the wood is, the more expensive it is.

There are several types of wood to choose from that vary in appearance and performance. Some tree species are more durable than others or better suited to certain types of climates. Generally, the harder and more durable the wood is, the more expensive it is.

| Species | Cost per Sq. Ft. |

|---|---|

| Bamboo | $2–$6 |

| Brazilian walnut | $5–$10 |

| Cherry | $4–$7 |

| Cypress | $4–$6 |

| Hickory | $3–$7 |

| Mahogany | $6–$8 |

| Maple | $3–$10 |

| Pine | $2–$4 |

| Red oak | $2–$6 |

| Teak | $9–$13 |

| White ash | $5–$8 |

| White oak | $4–$7 |

Hardwood Flooring Cost by Thickness

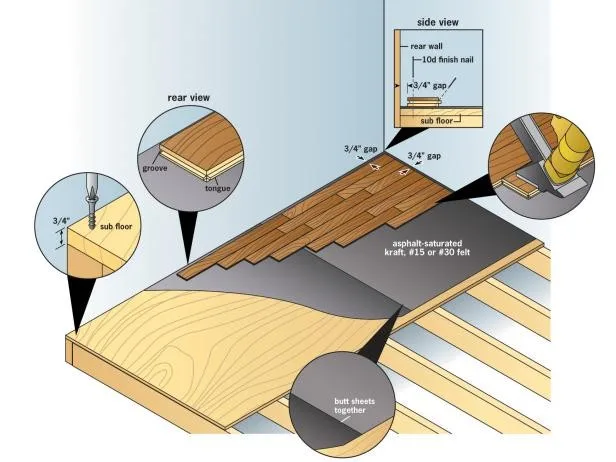

Traditionally, hardwood floorboards are three-quarters of an inch thick. Thinner boards—down to five-sixteenths of an inch thick—are less expensive, but you won’t be able to sand and refinish them as many times.

| Thickness | Cost per Sq. Ft. |

|---|---|

| 5/16” | $2–$5 |

| 3/4” | $3–$10 |

| 7/8” | $5–$15 |

Hardwood Flooring Cost by Grade

Solid hardwood flooring comes from living trees, so it’s not as standardized in quality as factory-made flooring material. Different vendors have different standards for grading their products’ quality; for example, some grades refer to grain pattern, texture, or appearance rather than durability. In general, hardwood boards of the same species and cut have three tiers of quality that determine their cost:

| Grade | Cost per Sq. Ft. |

|---|---|

| Low-tier | $2–$6 |

| Mid-tier | $5–$10 |

| High-tier | $8–$18 |

Hardwood Flooring Cost by Cut and Grain

The way wood is cut creates its grain pattern, which can play into price relative to the species of tree. Plain-sawn or flat-sawn planks are cut parallel to the tree’s growth rings to create a wave or flame-like grain pattern. Quarter-sawn planks, on the other hand, are cut at a 60–90 degree angle from growth rings for a straighter grain pattern. Flat-sawn boards are more common and therefore less expensive, while quarter-sawn boards are pricier but wear more evenly. The rarest and most expensive are rift-sawn boards, which have the most linear grain pattern but create the most waste.

Plain-sawn or flat-sawn planks are cut parallel to the tree’s growth rings to create a wave or flame-like grain pattern. Quarter-sawn planks, on the other hand, are cut at a 60–90 degree angle from growth rings for a straighter grain pattern. Flat-sawn boards are more common and therefore less expensive, while quarter-sawn boards are pricier but wear more evenly. The rarest and most expensive are rift-sawn boards, which have the most linear grain pattern but create the most waste.

To estimate how much your flooring will cost, use the equation below, as illustrated in our Complete Guide to Hardwood Flooring article.

Free Quote: Get your hardwood flooring quote today

Hardwood Flooring Cost Factors

Beyond the type of wood, here are some factors that contribute to the total cost of hardwood flooring installation:

- Alternative flooring options

- Floor joist repairs

- Finish and coating

- Installation and labor

- Repair, replacement, and refinishing

Alternative Flooring Options

If you love the look of solid wood flooring but traditional or engineered hardwood is beyond your budget, there are alternative flooring options that mimic the appearance of wood. Vinyl or laminate flooring and porcelain tiles can be manufactured to look like wood for a fraction of the cost. Alternative real wood options, such as floating floors and click-and-lock paneling, can help you save money on installation.

Vinyl or laminate flooring and porcelain tiles can be manufactured to look like wood for a fraction of the cost. Alternative real wood options, such as floating floors and click-and-lock paneling, can help you save money on installation.

Floor Joist Repairs

When you replace your existing flooring, you may discover that the subfloor or joists have mold, insect, or water damage. In this case, you’ll need to have the joists repaired for an average cost of $2,000–$5,000 before any work can be completed.

Finishing and Coating

When installing new hardwood floors, you have two choices: boards that have been prefinished at the factory or unfinished boards that are finished with sealant following installation. Unfinished boards are less expensive but come with higher labor costs, since the finishing must be done on-site. Additionally, different types of finish have different costs, with polyurethane on the low end and penetrating resin finish on the high end.

Installation and Labor

Hard and exotic woods have higher material and installation costs, while softwoods like pine are easier to work with and cheaper to install. Parquet and small wood tiles with intricate patterns are pricier to install, as is flooring in rooms with unusual layouts or staircases.

Parquet and small wood tiles with intricate patterns are pricier to install, as is flooring in rooms with unusual layouts or staircases.

Repair, Replacement, or Refinishing

Hardwood flooring may be expensive to install, but you can easily refinish it. A professional sanding and floor refinishing project costs $3–$8 per square foot and will get rid of dents, dings, and even gouges. You may even refinish your floors yourself. Replacing individual boards will cost more, but it will still be just a fraction of the overall cost of having new floors installed.

Free Quote: Get your hardwood flooring quote today

Types of Hardwood Flooring

One of the most important decisions you’ll make when installing new hardwood floors is choosing the wood type. Here are some of the most common types of wood flooring and their characteristics:

- Maple: Light coloring, medium density, good for high-traffic areas

- Pine: Low cost, very soft, prone to dents, difficult to refinish

- Bamboo: Durable, shows few scratches, termite-resistant

- White ash: Light color, bold grain, medium density

- Hickory: High density and hardness, variable in color

- Red oak: Consistent color and finish, high durability, medium price

- White oak: More water-resistant than red oak, lighter color

- Brazilian walnut: Rich color, high durability

- Cypress: Moderate durability, termite-resistant

- Cherry: Rich color, soft, best for bedrooms and low-traffic areas

- Teak: High price, very hard, scratch-resistant

- Mahogany: Dark color, ages well, medium price

Pros and Cons of Hardwood Flooring

Below, we outline the benefits and drawbacks of installing this type of flooring.:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/19504802/12_hardwood_floors.jpg)

Pros of Hardwood Flooring

Durability and value are among the top benefits of hardwood flooring. Some other pros include the following:

- Long-lasting with a 50- to 100-year lifespan

- Good for increasing resale value

- Easy to repair and refinish

- Relatively low-maintenance

- Versatile in appearance

- Less allergenic than carpeting

Cons of Hardwood Flooring

There are several cons to consider before installing hardwood flooring:

- Expensive to install

- Prone to scratches and gouges

- Susceptible to humidity and moisture damage

- Noisy when walked on, as they tap and creak

- Difficult for people and pets with mobility problems

DIY vs. Professional Hardwood Flooring Cost

Installation and labor are two of the most expensive aspects of installing hardwood flooring. To cut down on costs, homeowners may be tempted to take on the project themselves. There are some types of wood flooring, like click-and-lock wood tiles and floating flooring, that experienced DIYers may be able to install themselves. When it comes to traditional hardwood plank flooring, however, the job is best left to the professionals.

To cut down on costs, homeowners may be tempted to take on the project themselves. There are some types of wood flooring, like click-and-lock wood tiles and floating flooring, that experienced DIYers may be able to install themselves. When it comes to traditional hardwood plank flooring, however, the job is best left to the professionals.

Flooring contractors don’t necessarily have to be licensed, but it takes ample training and experience to properly account for variables such as changing temperatures, humidity, and moisture protection. Improperly installed wood floors are prone to cracking, bowing, and warping over time, so if you’re investing in hardwood flooring, we strongly recommend you have it professionally installed.

Free Quote: Get your hardwood flooring quote from pros near you today

How To Save on Hardwood Flooring Costs

Here are a few ways to save money on the overall project cost without having to do the work yourself.

Prioritize Savings Over Appearance

Think about wood flooring materials beyond just the color and finish. Look for a less expensive grain (plain-sawn), type of hardwood (pine, red oak, bamboo), and thickness (5/16”). You’ll also pay less for boards with more “character,” i.e., knots, varied colors, etc.

Look for a less expensive grain (plain-sawn), type of hardwood (pine, red oak, bamboo), and thickness (5/16”). You’ll also pay less for boards with more “character,” i.e., knots, varied colors, etc.

Consider Engineered Wood

It can cost more to install, but you can often save money by opting for engineered wood with non-exotic veneers. Depending on the type of panels, you may even be able to install it by yourself.

Whenever Possible, Refinish

If you already have hardwood floors, refinishing the old flooring will cost much less than installing new wood. Unless there are deep gouges or the floors have significant moisture damage, refinishing is usually the way to go.

How To Install Hardwood Floors

Installing hardwood flooring is a complicated process, but here are the basic steps. You can learn more in our comprehensive guide to hardwood floor installation.

- Let the flooring material acclimate to the home’s temperature and humidity.

Check for warps or other damage to the material.

Check for warps or other damage to the material. - Remove the old flooring and clean and prepare the subfloor.

- Lay and install the boards while staggering the gaps, leaving room for expansion and using boards from different boxes.

- Cut any excess underlayment, then sand and stain the boards.

- Add thresholds.

How To Hire a Professional

When choosing a flooring contractor, here are some things to keep in mind:

- Make sure the company is fully licensed, bonded, and insured.

- Find out which contractor or sub-contractor will perform the work.

- Ask for references from past clients and view samples of the company’s previous work.

- Read customer reviews on sites such as Yelp, TrustPilot, and Google Reviews.

- Check the company’s Better Business Bureau (BBB) rating and accreditation status.

- Get every estimate and warranty in writing.

- Examine at least three companies before making your choice.

Free Quote: Get your hardwood flooring quote from pros near you today

Our Conclusion

Hardwood flooring costs are substantial, and no flooring material is perfect. Still, hardwood floors have a lot of benefits, including a high return on investment. You also have more options than just installing wide planks in the traditional manner. Take some time to explore your wood flooring options and how they fit into your budget to determine whether hardwood floors are the right choice for your home.

FAQs About Hardwood Flooring

To share feedback or ask a question about this article, send a note to our Reviews Team at [email protected].

2022 Hardwood Flooring Cost + Installation Cost Per Square Foot

Hardwood Floor Installation Costs

The average cost to install hardwood flooring is $4,213 with most homeowners spending between $2,311 and $6,115. On the low end, you can expect to pay $6 to $11 per square foot, and on the high-end prices range from $12 to $23 per square foot for both materials and installation. The installation includes finishing, trim, and removal of your old floor.

On the low end, you can expect to pay $6 to $11 per square foot, and on the high-end prices range from $12 to $23 per square foot for both materials and installation. The installation includes finishing, trim, and removal of your old floor.

| National Average Cost | $4,213 |

| Minimum Cost | $1,200 |

| Maximum Cost | $11,100 |

| Average Range | $2,311 to $6,115 |

With many available options, it is important to understand what variables will impact the final cost of your project. Whether you opt for traditional hardwood materials or engineered hardwood flooring, you need to choose an option that makes sense for you and your home. This guide is intended to help you through your wood flooring journey, helping you better understand the costs involved. That way, you can plan accordingly and most importantly, stay within your budget.

That way, you can plan accordingly and most importantly, stay within your budget.

Table Of Contents

- Hardwood Floor Installation Costs

- Per Square Foot

- Average Labor Cost To Install

- Laminate Vs. Hardwood

- Carpet Vs. Hardwood

- Tile Vs. Hardwood

Hardwood Flooring Installation Cost Per Square Foot

Hardwood flooring installation costs $6 to $23 per square foot with most homeowners spending between $8 and $15 per square foot on average. The main pricing factors include the type of wood you select and labor costs for professional installation.

| Hardwood Type | Low Grade | Mid Grade | High Grade |

|---|---|---|---|

| Traditional Hardwood | $6 – $11 | $9 – $18 | $12 – $23 |

| Engineered Hardwood | $6 – $14 | $9 – $19 | $12 – $23 |

Average Labor Cost For Installing Hardwood Floors

The average labor cost for installing hardwood floors ranges from $3 to $9 per square foot to hiring a professional contractor. Expect labor costs to make up approximately 50% of your total project cost. Always get multiple bids from various hardwood flooring contractors so you can make an educated decision.

How Much To Install Hardwood Floors On 1,000 Sq. Feet?

The average cost to install hardwood floors on 1,000 sq. feet is between $6,115 and $10,140 with most homeowners spending about $8,127 for materials and professional labor.

Hardwood Stairs Cost

Installing hardwood stairs costs between $100 and $200 per step on average, which includes all materials and professional labor. Typically a flight of stairs has 12 to 15 steps, which would be a total of $1,200 to $3,000.

Return to Top

Traditional Wood Flooring Costs

The cost of new wood floors ranges from $6 to $13 per square foot while engineered hardwood is slightly more expensive at an average of $6 to $15 per square foot for both materials and installation. Traditional flooring is solid wood without any layers – in comparison to engineered wood, which is constructed with multiple layers of hardwood and plywood. Both are durable, high-performance options, so it just depends on your personal preference.

| Floor Grade | Materials Cost (SF) | Labor Cost (SF) | Total Cost(SF) |

|---|---|---|---|

| Lowest tier | $3 to $6 | $3 to $5 | $6 to $11 |

| Middle tier | $5 to $10 | $4 to $8 | $9 to $18 |

| Highest tier | $8 to $15 | $4 to $8 | $12 to $23 |

The hardest hardwoods, such as walnut and oak are the most durable. However, they are also more costly. Although prices will vary depending on the supplier, you can expect three key pricing groups based on the hardness and rarity of the wood.

However, they are also more costly. Although prices will vary depending on the supplier, you can expect three key pricing groups based on the hardness and rarity of the wood.

Wood Flooring Grades

Wood flooring typically comes in 3 different grades. Also, wood floors are available in narrow boards or planks. These range of approximately 3 inches to 7 inches in width respectively. In terms of how much traditional wood flooring costs, the most significant factor is, of course, the type of wood you select.

- Lowest tier – Soft woods, including pine and poplar, generally cost anywhere from $3 to $6 per square foot, as well as an additional $3 to $5 for installation.

- Middle tier – These woods will be hardwood options, which are relatively common, including oak, teak, or American cherry. In comparison, you can expect to pay anywhere between $5 to $10 a square foot for the flooring itself, in addition to around $4 to $8 per square foot for professional installation.

- Highest tier – The most expensive hardwoods are those that are rare and/or exotic, such as tigerwood, mahogany, or Brazilian walnut. These typically cost anywhere between $8 to $15 per square foot, in addition to $4 to $8 per square foot for installation.

Return to Top

Engineered Hardwood Costs

Installing engineered hardwood costs $6 to $11 per square foot on the low end, all the way up to $12 to $23 per square foot for exotic hardwoods. When comparing traditional and engineered wood, the main difference is in the construction of the wood itself. As discussed, traditional wood is just solid wood, prepared into boards or planks.

In contrast, engineered wood is constructed with multiple layers of hardwood and plywood. Based on the way these layers are created and positioned, engineered hardwood helps prevent any bowing or warping of the wood following exposure to moisture.

| Floor Grade | Materials Cost (SF) | Labor Cost (SF) | Total Cost(SF) |

|---|---|---|---|

| Lowest tier | $3 to $5 | $3 to $9 | $6 to $11 |

| Middle tier | $5 to $10 | $4 to $9 | $9 to $19 |

| Highest tier | $8 to $14 | $4 to $9 | $12 to $23 |

Available in the most popular species, including maple, hickory, and oak, you will also find different finishes, such as matte, semi-gloss, or gloss. Based on the number of engineered wood flooring options available today, you benefit from greater flexibility in regards to pricing and where you can install the wood.

Hardwood Flooring Grades

Similar to traditional wood, engineered hardwood is offered at varying grades and price points:

- Lowest tier – This will be your most basic engineered hardwood, consisting of three layers, finished with a top layer of veneer.

The cost of material will be between $3 and $5 per square foot, and depending on the complexity of the project/layout, installation can cost anywhere between $3 and $9 per square foot.

The cost of material will be between $3 and $5 per square foot, and depending on the complexity of the project/layout, installation can cost anywhere between $3 and $9 per square foot. - Middle tier – You can also invest in an upgraded version, which typically includes a five-layer core, finished with a thicker veneer. Installation costs are generally the same. However, the wood itself is slightly more, costing an average of $5 to $10 per square foot.

- Highest tier – Top-of-the-line engineered hardwood can have as many as seven layers or more. The top veneer is also significantly thicker, and the layers are often made from exotic woods. These typically cost around $8 to $14 per square foot, with installation costs remaining the same.

In some cases, homeowners install engineered hardwood below ground level without any worry. Once again, this is possible because engineered hardwood offers greater heat and moisture resistance than solid woods. It can also be used in places that traditional hardwoods are not typically used, such as in the kitchen, in basements, or in high-humidity summer homes.

It can also be used in places that traditional hardwoods are not typically used, such as in the kitchen, in basements, or in high-humidity summer homes.

Return to Top

Hardwood Flooring Prices By Type

Pine is the cheapest hardwood with average prices of $2 to $4 per square foot not including installation. Certain high-end engineered hardwoods are priced between $10 and $13 per square foot such as Engineered Heart Pine or Engineered White Ash.

To help guide your decision, here are some of the commonly used and requested solid hardwood species.

| Hardwood Type | Cost Per Square Foot |

|---|---|

| Pine | $2 – $4 |

| Bamboo | $2 – $4 |

| Red Oak | $2 – $6 |

| Maple | $3 – $6 |

| Hickory | $3 – $6 |

| White Ash | $5 – $6 |

| Brazilian Walnut | $5 – $9 |

| Engineered Heart Pine | $10 – $11 |

| Engineered Maple | $10 – $12 |

| Engineered White Ash | $12 – $13 |

Pine Hardwood Flooring

Pine hardwood flooring costs $2 to $4 per square foot, while engineered heart pine is around $10 to $11 per square foot. A softwood, pine isn't the best option when pets are in the house, as it can scratch and dent more easily than some of the other woods available. However, the appearance of pine is stunning, offering warm tones that range of beige to amber, vintage charm, and rustic knots throughout.

A softwood, pine isn't the best option when pets are in the house, as it can scratch and dent more easily than some of the other woods available. However, the appearance of pine is stunning, offering warm tones that range of beige to amber, vintage charm, and rustic knots throughout.

Maple Hardwood Flooring

This wood is sturdy and much more resistant to dents, making it a great material to use in high-traffic areas. The only downside is that it can be harder to work with which is why professional assistance is recommended. The coloration ranges from white to a light red tone. Average cost: $3 to $6 per square foot. In comparison, engineered maple typically goes for $10 to $12 per square foot.

Ash Hardwood Flooring

Ash is durable and typically tough to stain hardwood. Its coloration ranges from soft tan to pale gray with a bold grain like oak. Heartwood Ash varies from light tan to dark brown. Ash hardwood costs $5 to $6 per square foot, compared to $12 to $13 per square foot for engineered White Ash.

Bamboo Hardwood Flooring

Bamboo hardwood comes in a wide variety of colors with interesting patterns. Although it's not a real hardwood, it shares many characteristics such as water resistance, durability, and styles. Pricing for bamboo flooring ranges from $2 to $4 per square foot.

Hickory Hardwood Flooring

Hickory is a durable wood that embodies fantastic grain patterns with many color variations. It works great in high-traffic areas, and prices range from $3 to $6 per square foot.

Oak Hardwood Flooring Cost

Oak hardwood contains rich detailing and deep patterns and earth tones. Red Oak has a narrow but visible grain in reddish earth tones. Oak is a mid-level wood floor material with prices ranging from $3 to $10 per square foot for just the materials.

Walnut Hardwood Flooring

This wood comes in many different exotic brownish shades with a distinctive grain. It's extremely hard and durable with a price tag at $5 to $9 per square foot for just the materials.

Whether you prefer bamboo or red oak, traditional hardwood costs less than engineered wood types. Remember, engineered wood flooring offers increased durability and higher moisture resistance. This means that if you have young children or pets, you should consider engineered wood.

Laminate Vs. Hardwood Cost

The average cost to install laminate flooring is between $3 to $8 per square foot compared to hardwood floors at $6 to $12 per square foot. Laminate flooring installation costs $1,411 and $3,395 with most homeowners paying around $2,352 for professional installation.

Carpet Vs. Hardwood Cost

The average cost to install carpet ranges from $2 and $4 per square foot, compared to hardwood flooring which costs an average of $6 to $12 per square foot installed.

Tile Vs. Hardwood Cost

Tile installation costs $2 to $7 per square foot for vinyl or lamainte, and $5 to $10 per square foot for porcelain or ceramic, while hardwood flooring ranges from $6 to $12 per square foot.

Return to Top

Hardwood Flooring Pros And Cons

There are multiple reasons why people chose wood floors over other possibilities.

- Visual appeal – While available with patterns (usually structured shapes), real hardwood flooring will create a natural look because of each piece’s unique color and grain. There is a vast array of wood flooring options that will bring your creative vision to life and be perfectly tailored to your color scheme and decor plans.

- Easy maintenance – Hardwood floors are low maintenance, and a typical cleaning process includes weekly sweeping, dry mopping, or vacuuming and the occasional deep clean. When compared to carpet, wood floors with the right finish are wonderfully stain and odor resistant.

- Life span – Quality wood flooring that has been installed and finished professionally can last for generations, even in high-traffic areas such as the kitchen, dining room, and hallway.

- High return on investment – Whether you are replacing a wood floor or upgrading flooring, quality wood flooring installed by a professional contractor will always raise the property value, making it a long-term investment.

- Eco-friendly – In addition to being kinder to those sensitive to allergens, hardwood floors are also more helpful to the environment because wood is a renewable resource. This is even more so with some options that incorporate bamboo elements because bamboo grows very quickly.

- Acoustics – A real hardwood floor has a solid sound to it when you walk across the floor, and it will very much improve the acoustics in a room, making your home theatre or music system sound even better.

How Long Do Hardwood Floors Last?

It is not unusual to see wood flooring throughout the entire home because of its longevity over carpet and tile. If treated well, the life of a wood floor can stretch to over forty years, and even then, it can be sanded, stained, and varnished—significantly cheaper than having it replaced.

Return to Top

Hardwood Floor Finishes

To extend your floors durability and longevity, add a coating of a protective seal called a finish. These finishes are usually made of either polyurethanes or prefinished UV-cured urethane, oils, or oil hybrids.

- Factory-finished wood flooring has the stain and protective topcoat already applied as part of the manufacturing process. Because this wood will arrive at your home already protected, you will be looking at a shorter time to project completion—because installers don’t need to finish the wood and you don’t have to wait before allowing your family back in to walk on it.

- Unfinished wood flooring, which is usually the cheaper option in regards to raw materials, can have the finish completed in your home after the contractor has it installed. The finish treatments to be applied by your contractor will add to your labor costs.

- Polyurethane finishes are more resistant to stains and damage, and most suitable in homes with small children and pets; but when significant damage occurs, it is usual for a whole board to be replaced, followed by buffing and recoating the entire floor.

- Oil finishes result in a more natural look and afford easier maintenance of the wood. Not being as hard as the polyurethane finish, the finish can damage more easily, but you can take care of nicks and scratches by applying more oil and allowing it to soak in.

On average, prefinished wood costs around $2 more per square foot than unfinished wood, but it is less expensive when the finishing costs for unfinished wood are added in.

Return to Top

Hardwood Flooring Sizes

- Thickness – A standard thickness for wood flooring is 3/4”, but some vendors produce a range of thicknesses down to 5/16.”

- Width – Standard widths of wood for flooring are usually 2¼ wide, and broader pieces, known as plank floors, are available in 3”– 6”. Typical, and also cheaper, installs will feature the standard widths and uniform lengths; however, a more organic and natural appearance in your flooring can be accomplished using wider wood or combining wood of different lengths.

- Length – Lengths of wood will vary by manufacturer and will generally carry a length classification. Typical plank lengths are:

- Short - 3– 6’

- Medium - 7’

- Long - 8–10’

Some manufacturers, like Hull Forest, sell pieces of Eastern White Pine as long as 16 feet. Longer pieces of wood come from older trees, so they will be of a higher quality and arrive at a higher price.

Return to Top

Additional Cost Considerations

Hardwood Floor Refinishing

Hardwood floor refinishing costs $2 to $7 per square foot, depending on the square footage, location, staining, finish type, number of coats, and labor costs.

If you maintain a hardwood floor properly, it might never need refinishing. A solid wood floor can last from 20 to 160 years without a refinish, depending on its thickness and quality.

Trim and Molding Costs

Trim costs about $5.50–$9 per linear foot to have it installed or $1. 50 per linear foot to paint it a new color. The cost to remove and reinstall your baseboards will cost about $150.

50 per linear foot to paint it a new color. The cost to remove and reinstall your baseboards will cost about $150.

Once your wood flooring is installed, the contractor installs trim molding on the base of the wall around the edges to hide any gaps. Even in the uncommon situation where there are no gaps, over time, with contraction and expansion of the wood and slight shifts in the foundation, they will become visible without trim being installed.

Cost To Remove Hardwood Floors

Before installing new hardwood floors, you may have to remove your current floors if they do not create a proper surface. Expect to pay between $400 to $550 to remove existing hardwood floors or $1 to $2 per square yard to remove any existing carpet.

Return to Top

Estimating Your Hardwood Flooring Costs

The best thing you can do to save money is to shop around. Choose 2-3 styles and/or wood types so that you can easily compare. To ensure that you remain within your budget, contact contractors to obtain an installation quote.

To ensure that you remain within your budget, contact contractors to obtain an installation quote.

Also, ensure that the workspace is ready-to-go when contractors arrive. This means moving furniture and even removing old flooring. You can then purchase wood flooring yourself, pick it up, and bring it home. That way, the flooring company will only need to install the flooring – not supply it or remove your old floor.

Last but not least, if you have a tight budget, consider the layout of your design and keep it as simple as possible. As soon as you request bordering or inlaid patterns, you can anticipate significantly higher costs.

Where to buy:

- Online – When shopping online, request flooring samples so that you can determine the best options for your home. If you are not fixated on a particular species or color of wood, you can often find some great deals. Start by looking at online suppliers that offer free shipping or free local pick-up.

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/19494392/floor_5.jpg)

- Local retailers – Home improvements stores often carry a wide range of styles at varying price points. You can request samples to take home and based on the size of the area you want to floor, you can ask for a rough estimate.

- Discount options – There are also lumber liquidators who sell a vast selection at a reduced cost. Once again, if you're open to various types of wood and varying styles, this is a great option.

Selecting Your Flooring Contractor

When creating your shortlist of contractors, there are a few criteria you can consider that may help set your mind at ease. Look for contractors with some or many of the following boxes checked:

- Members of the Better Business Bureau

- Decades in business

- Great reviews on HomeGuide and Google

- Specialize in hardwood flooring

- Licensed, bonded, and insured

Whether you have recently bought a new home or plan to renovate your current residence, new flooring can make all the difference. Although it is more expensive than other options on the market, it tends to be the preferred choice. Hardwood flooring is known for its warm, character-rich appearance, versatility, and durability. Also, hardwood floors add value to a home.

Although it is more expensive than other options on the market, it tends to be the preferred choice. Hardwood flooring is known for its warm, character-rich appearance, versatility, and durability. Also, hardwood floors add value to a home.

Get free estimates on HomeGuide from trusted flooring professionals:

Get free estimates

Prices for laying a parquet board per m2 - the cost of installing a parquet board with glue in Moscow

The cost of laying a parquet board per square meter will please you very much. We don't do cheats. When confirming the order, we draw up an accurate estimate, which does not change during work. The price of laying a parquet board in Moscow is calculated individually, based on the selected materials, the area of \u200b\u200bthe room and the complexity of the work.

Parquet board is a natural floor covering that consists of several layers of wood glued together. The top most valuable layer is called veneer, it is about 3-4 mm thick and is usually made from expensive and rare wood species.

The veneer can be 1, 2 and 3-strip, the last two options consist of dies glued together, which create an imitation of piece parquet.

PRICES

for laying boards

| Service | Price |

|---|---|

| 1. Underlay deck | 50m2 |

| 2. Laying parquet board - floating | 450m2 |

| 3. Floating installation (DIAGONAL) | 500m2 |

| 4. Laying parquet board with adhesive (STRAIGHT) | 550m2 |

| 5. Laying parquet board with adhesive (DIAGONAL) | 690m2 |

| 6. Skirting board assembly (Plastic) | 180pg/m |

TERMS

FOR INSTALLATION

| Area | Without plywood | From plywood |

|---|---|---|

| up to 15 M 2 | 1 day | 1-2 days |

| 15-25 M 2 | 2-3 days | 3-4 days |

| 25-40 M 2 | 3-4 days | 4-5 days |

| 40-55 M 2 | 4-5 days | 5-6 days |

| 55-70 M 2 | 5-6 days | 6-7 days |

| Over 70 M 2 | from 5 days | from 7 days |

The lower part consists of one or more layers, made from inexpensive and soft wood. All layers fit together perfectly and are glued perpendicular to each other. Using this method, their size does not change throughout the entire period of operation, even if the humidity in the room is increased or there are temperature fluctuations in winter or summer. The quality and price of the material are directly proportional to each other. The higher the cost, the better the quality.

All layers fit together perfectly and are glued perpendicular to each other. Using this method, their size does not change throughout the entire period of operation, even if the humidity in the room is increased or there are temperature fluctuations in winter or summer. The quality and price of the material are directly proportional to each other. The higher the cost, the better the quality.

The price of a board is affected by the following factors:

- The size of the plates

- Number of strips

- Number of layers (depending on thickness)

- Wood species of the top expensive layer

- Tree view of the bottom layer

- Veneer type

- Veneer cutting method

- Veneer Heat Treatment

- Type of top layer protective coating.

RECOMMENDATIONS

OUR TECHNOLOGY

- High-quality base

- Substrate from 2 to 4 mm

- If glued only on strong glue

- The service life of the docks before the first grinding is 15 years.

Leave a request

And we will call you back

Technologist Alexey +7 (968) 738-54-60

within an hour we will contact you!

Laying

parquet boards

in a straight line from 450 m2

diagonal from 500 m2

adhesive method from 550 m2

PRICES for works

PER M2

| Service | Old price | Price RUB |

|---|---|---|

| 1. Screed primer | 100 rub/m2 | 50 rub/m2 |

| 2. Solid board decking with adhesive SPAX screws (COATED) | 1050 rub/m2 | 950 rub/m2 |

| 3. Solid board decking with SPAX self-tapping screws (UNCOATED) | 900 rub/m2 | 800 rub/m2 |

| 900 rub/m2 | 850 rub/m2 | |

5. Floorboard installation, floating Floorboard installation, floating | 500 rub/m2 | 450 rub/m2 |

| 6. Floating parquet flooring (DIOGANAL) | 650 rub/m2 | 500 rub/m2 |

| 7. Installation of parquet boards with glue (DIRECT) | 700 rub/m2 | 550 rub/m2 |

| 8. Installing the parquet board with glue (DIAGONAL) | 800 rub/m2 | 690 rub/m2 |

| 9. Installing curb | 500 rub/m2 | 400 rub/m2 |

| 10. Installation of frieze | 950 rub/m2 | from 850 rub/m2 |

11. French Tree French Tree | 1950 rub/m2 | 1500 rub/m2 |

| 12. Module deck | 1950 rub/m2 | 1200 rub/m2 |

| 13. Artistic parquet flooring | 3500 rub/m2 | 2500 rub/m2 |

| 14. Complex parquet laying (braided, sheremetyevka) | 950 rub/m2 | 850 rub/m2 |

| 15. Diagonal Squares | 1200 rub/m2 | 1100 rub/m2 |

| 16. Insert "Sockets" | 4500 rub/m2 | 3400 rub/m2 |

Price list for additional work

| Service | Price | |

|---|---|---|

| Parquet floor removal | | 500 rub/m 2 |

| Removing solid board | | 550 rub/m 2 |

| Linoleum removal | | 40 rub/m 2 |

| Laminate removal | | 50 rub/m 2 |

| Filling screeds up to 20 mm | | 300 rub/m 2 |

| Screed up to 40 mm | | 400 rub/m 2 |

| Screed grinding with diamond disc | | 249 rub/m 2 |

| Base cleaning | | 50 rub/m 2 |

| Epoxy primer application | | 200 rub/m 2 |

| Multimoll flooring | | 149 rub/m 2 |

| Plywood cutting | | 60 sheet |

| Lifting plywood in an elevator | | 99 sheet |

| Parquet lifting | | 99 pack |

Prices for skirting board installation

| Service | Price | |

|---|---|---|

| Removing the skirting board | | 50 rub/m 2 |

| Installation of wooden skirting up to 50 mm high | | 200 rub/m |

| Installing a wooden skirting board 50 to 70 mm high | | 230 rub/m |

| Installing a wooden skirting board 70 to 90 mm high | | 250 rub/m |

| Installing a wooden skirting board 90 to 110 mm high | | 300 rub/m |

| Installing a wooden skirting board over 110 mm high | | 350 rub/m |

| Baseboard varnishing | | 50 rub/m |

| Installation of plastic skirting board | | 150 rub/m |

| Installation of euro plinth with clips | | 450 rub/m |

| Installation of flexible polyurethane skirting | | 550 rub/m |

Features of surface preparation for laying work.

Before you start laying parquet boards in Moscow, the flooring must be carefully primed. If it can form moisture, then it is simply necessary to prime the surface well with epoxy or polyurethane two-component primers before starting all work.

If this is not done, then you will not be able to cope with the impact of liquid on your parquet. The substrates that isolate from the liquid, on the contrary, will begin to accumulate water and its excess content will begin to flow into the room, which will contribute to the formation of fungus.

In which direction should the board be laid on the plywood?

Recommended to lay perpendicular to windows. It can be a canvas or have joints - it doesn't matter. When using the floating method of laying a parquet board, all the joints between the pieces are hidden under small overlays, and with the adhesive laying technology, special cork compensators are mounted. The direction of laying, the price per m2 of which we have is quite affordable, depends entirely on the placement of window openings in the room, almost always the slabs are located perpendicular to the window.

The parquet board is laid in two different ways:

It creates an excellent acoustic effect on glue, such a floor does not loosen from temperature and humidity changes, it lasts much longer, it can be scraped up to 3 times. Laying a board on an underlay is much faster and cheaper than using glue, it is much easier to dismantle it after the expiration of its service life to install new material.

If you have purchased an expensive and very beautiful parquet board, do not skimp on the work of craftsmen. Buy high-quality expensive glue or seek advice from my qualified specialists. Here you can get acquainted with the prices for laying.

If you do not plan to spend a lot, then do not buy expensive options, lay an ordinary inexpensive board in a floating way.

Cost of laying a parquet board per square meter for glue and technology

Laying a parquet board (the cost of work depends on the area of the room) is allowed only on a perfectly flat surface. Glue will stick the dice to any base. However, if the coating has defects, then they must be eliminated. Screeds are usually primed and leveled using a self-leveling floor, and scraping is carried out on wooden surfaces.

Glue will stick the dice to any base. However, if the coating has defects, then they must be eliminated. Screeds are usually primed and leveled using a self-leveling floor, and scraping is carried out on wooden surfaces.

If parquet boards are laid on wood flooring, then special pins are driven into the grooves of the boards. This is done so that the board adheres better to the surface. If it is not possible to do this, then everything that is heavy is placed on the boards. You can simply collect water in five-liter bottles and put it on the parquet.

The cost of laying on the underlay and the technology of work

The floor is being prepared, then the underlay is mounted, which is glued with adhesive tape. Laying a parquet board, the price for it varies depending on the area of the room, is carried out in strict accordance with the instructions. A gap of 1 cm is left between the wall and the floor covering, in case of expansion of the board due to temperature rise and humidity fluctuations. If there are pipes in the floor covering, then a hole is carefully drilled in the board, which (at the request of the customer) is sealed with a special insert. After completion of all work, the plinth is installed.

If there are pipes in the floor covering, then a hole is carefully drilled in the board, which (at the request of the customer) is sealed with a special insert. After completion of all work, the plinth is installed.

How to choose an underlay for floating installation?

When performing professional underlayment, the first step is to choose the material for the underlayment. There are 5 types of substrates: flexible ones are rolled up, and rigid ones are made in rectangular or square shape. At first it may seem that even an inexperienced person can choose a substrate, but everything is not so easy here. There is a certain scheme for selecting the substrate for a particular room. Not all of them protect the flooring from moisture, which means that you will still have to spend money on plastic wrap.

Underlays can also be used to slightly isolate the room from sound or smooth out existing surface irregularities. Under the last two versions of the substrates, it is recommended to lay a polyethylene film to protect against moisture; in the first three options, its use is not necessary.

Underlay types:

- Polyethylene foam (high waterproofing).

- With foam balls placed between two layers of foil for excellent waterproofing.

- Rubber and bituminous backing with good moisture protection.

- Natural cork backing is not waterproof.

- Expanded polystyrene (extruded) in mats does not protect the floor from moisture

- Interesting article how to install modular floor

Leave a request

And we will call you back

Technologist Alexey +7 (968) 738-54-60

within an hour we will contact you!

Parquet installation | parquet board

- home

- Floor installation and laying of floor coverings

Phone

Why us

Fixed price

Price is fixed and does not change during the process

Warranty up to 5 years *

Did something go wrong? We will come, fix it

German equipment

We use the most accurate equipment

Official contract

We will write everything down and take into account

Pay attention! You lose the extended warranty if you order styling not from us!

Why? Everything is simple!

Every flooring has its own characteristics and laying restrictions! Our specialists regularly undergo advanced training from manufacturers with whom we cooperate! We provide an extended warranty up to 5 years *

Installation by private craftsmen

- Before laying do not measure the parameters of the base

- Using a tool that is not designed for laying parquet

- Material overrun

- Do not leave deformation gaps

Installation by experienced craftsmen

- Use professional tools

- Mandatory verification and preparation of the base is carried out

- Compliance with the technological process

- Work is carried out in compliance with the requirements of manufacturers

- Work experience of specialists - from 3 years (with certification from manufacturers)

4 easy steps to perfect floor laying

Technologist visit

Estimate in 5 minutes

Negotiation of conditions and signing of the contract

Laying

Our works

Before

After

Before

After

Before

After

Before

After

Departure of a technologist to assess the quality of the base

Floor installation and flooring installation

Phone

By clicking on the "Submit request" button, I consent to the processing of personal data and agree to the policy privacy.

Installation cost

-

Laying laminated, PVC, SPC coatings on a substrate diagonally and parallel to the walls (minimum preparation of the base, laying)

from 610 r/m2

Laying laminated, PVC, SPC coatings on a Christmas tree pattern substrate (minimal preparation of the base, laying)

from 1260 r/m2

-

Laying parquet and engineered boards with interlocks in a floating way diagonally and parallel to the walls (minimum preparation of the base, laying)

from 840 r/m2

Laying of parquet and engineered boards with a locking joint in a floating way pattern Christmas tree (minimum preparation of the base, laying)

from 1380 R/m2

Gluing parquet and engineered boards to the screed diagonally and parallel to the walls (minimum base preparation, priming, laying)

from 1250 r/m2

Bonding parquet and engineered boards on a screed pattern (Christmas tree, French Christmas tree, square, wickerwork) (minimal preparation of the base, priming, laying)

from 2080 r/m2

Bonding parquet and engineered boards on a plywood layer pattern (Christmas tree, French Christmas tree, square, wickerwork) (minimal preparation of the base, priming, laying plywood, sanding the laid plywood, laying the board)

from 2770 r/m2

-

Bonding a solid board to a plywood base diagonally and parallel to the walls (minimum preparation of the base, priming, laying plywood, sanding the laid plywood, laying the board)

from 2110 r/m2

-

Bonding coated piece parquet on site (deck, tree, square) diagonally and parallel to the walls (minimal subfloor preparation, priming, laying plywood, sanding laid plywood, laying parquet, sanding and puttying parquet, priming and varnishing parquet)

from 4350 r/m2

-

Leveling the concrete base by grinding up to 5mm

from 510 r/m2

Floor milling

from 500 r/m2

Installation and tinting of the cork strip

from 700 r/m2

Good to know

When buying parquet, it is important to remember that it is absolutely not recommended to use it immediately after delivery. For at least a week, the materials should lie down in the place where the work will be done. Only during this time will the humidity of the room and the parquet board even out.

For at least a week, the materials should lie down in the place where the work will be done. Only during this time will the humidity of the room and the parquet board even out.

Before laying parquet, the strength of the substrate must be assessed; if it is low, then it is better to start by laying a separating substrate. The process of laying parquet

The process of laying parquet

A modern parquet board is a material that is completely ready for laying. It does not need to be oiled or varnished and does not need to be sanded. By law, laminate and parquet boards, as well as solid wood boards, are not required to be certified, but there are still some rules:

- internal humidity of the parquet board is 9±3%, while the rules do not provide for additional drying of the material;

- this does not change the rule not to unpack the parquet board for at least 48 hours after it has been delivered to the room where the repair is being carried out;

- it is necessary to open the package with parquet board before starting work;

- plastering, painting and wallpapering must be completed before laying the parquet in the room;

- works are carried out at an air temperature of +18°-23°C and an air humidity of 40-60%.

Methods for laying parquet boards

1. Floating method. The basis of laying is the castle connection.

2. Hard fastening method, in which the board is glued to the base.

Consider how to install parquet boards in more detail

Floating floor method. Individual parquet boards are not fixed to the base, but are fastened with a locking joint. A substrate is placed between the base and the parquet floor, on which the boards lie freely, assembled into a single layer.

This method has the advantage of high laying speed and reduced labor costs. The laying technology is so simple that often such parquet is laid on its own. The finished work, if necessary, can be disassembled and reused parquet board.

The floating floor method has its own disadvantages :

- when the floor begins to make sounds under steps or even characteristically creak;

- if the lock connection is deformed, then the whole structure ceases to be reliable;

- When parquet is used for a long time, sooner or later the question of its restoration arises.

Floating parquet cannot be sanded down for restoration.

Floating parquet cannot be sanded down for restoration.

In order to get the best possible performance when laying parquet flooring using the floating method, the following recommendations must be strictly observed: A polyethylene film with a thickness of 0.2 mm or 200 mKr is used as a membrane, it must be overlapped. Before laying, the film should be removed to the walls up to 50 mm, and at the end of work, but before installing the skirting boards, it should be cut to 10 mm. The next step is the laying of a sound-absorbing substrate 2-3 mm thick, it does not need to be glued;

With rigid fastening of parquet board , each plank is glued to the screed and fixed with weights while the glue dries.

The main advantage of a rigid mount is its high reliability. If such a parquet needs repair, then it will not be too difficult. Parquet laid in this way is very comfortable and does not creak. When laying, there is no need to use thresholds (for connection) between rooms.

There are some minor drawbacks. This method of laying is more time consuming, takes more time, requires a certain professionalism and, accordingly, is more financially costly.

Engineering board

This board has a special structure, it has a plywood base. This imposes certain nuances on the rules for its installation - it should always be only an adhesive method. If you use the floating method, then cracks and swelling are inevitable. An engineering board can be laid on a screed or on plywood sheets. In the latter case, for better fastening, you can use self-tapping screws.

* Depending on installation and type of flooring.

Step 1 of 6

Enter the area of your premises

m 2

Step 2 of 6

What type of flooring do you want to install?

Laminate

Parquet or engineered board with underlay

Parquet or engineered board with glue

Solid board

Block parquet.