Drywall ceiling hangers

T Quick Hanger, Ceiling Drywall Profile Carry Main Profiles

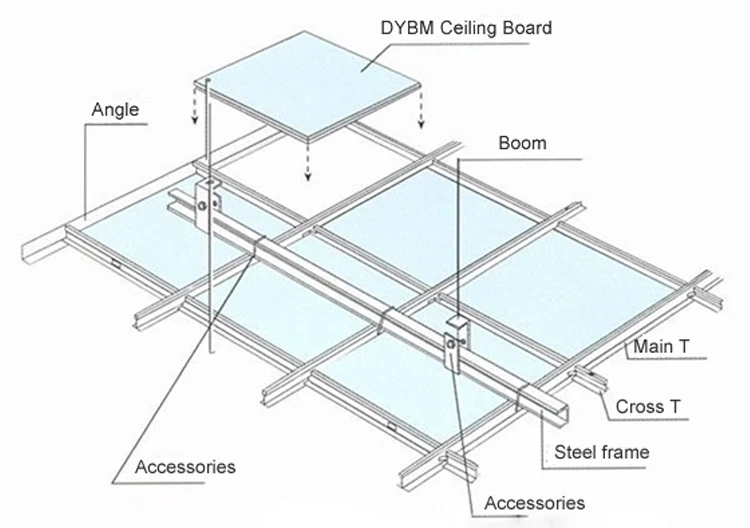

Firstly T quick hanger, suspended ceiling accessories.

Suspended ceiling hanger tongs are use to fit easily into C profiles. It is also install in the same direction as the C profiles to avoid any difficulties during installation.

Suspension rods are press on their springs during insertion. However, the hanger bars pass through the holes on the spring.

Hanger tongs used for fastening the profiles in plasterboard application. As it is in the form of a hanger, its name remains as a hanger. Hanger tongs known as the connection between the hanger bar and the c on the ceiling, for better fixation of the material with c profile in the plasterboard suspended ceiling application. Suspended ceilings also assume carrying duties. The suspension tong models used during the plasterboard suspended ceiling application preferred for fixing the c profile to the ceiling. As a fastener, it is highly prefer in the construction sectors. It’s prefer very often as it also takes on the task of carrying.

It’s use as a very useful product. It made of plaster, which is in the middle part of the drywall, both sides of which are cover with cardboard. This product, which is generally use in interior spaces, is easy to take shape. Therefore, it is prefer for many jobs.

Materials Use When Making Drywall

Plasterboard application, which provides a decorative appearance, has a wide range of usage. Suspended ceilings, preferred as partition walls in homes and workplaces, are also highly durable and quality products for water and fire. The suspended ceiling, which is a lightweight material, is fix to the area it is in by using the hanger and provides security during the usage phase. These products, which are both healthy and very useful, have a feature that does not crack, so they are use for a long time. A cleaner environment is create with spot lighting applied in the spaces and plasterboard ceiling application. Thanks to the system that eliminates electricity and cable pollution, more decorative shapes can be made on the ceiling.

Thanks to the system that eliminates electricity and cable pollution, more decorative shapes can be made on the ceiling.

There is no need to have any feature in the area where plasterboard application will be made. Suspended ceiling hanger is apply with the hanging wire attached. With the main carrier mounted on the C profile, a solid assembly is also made. Due to the fact that drywall walls do not have carrier features, a sufficient number of hangers should be use. The best products should be chose for durability. C profiles should be lay with a maximum interval of 60 cm. Suspended ceiling accessories are highly prefer during construction and decoration. Original products must be use. The quality of the materials used is very important due to the long duration of the work done. For this reason, quality is very important for doing such works.

Hanger Tongs Prices

Hanger tong prices are generally determine by the number of customers needs. Usually hanger tongs sold in thousands of packages. They are very cost effective products. You can supply hanger products from many companies that sell construction materials. Hanger is prefer very often in many areas. However, in order to determine how many you need, it is useful for the people who will do the necessary work to look at the application area. Before this hanger is supply, it is necessary to look at how many needed.

They are very cost effective products. You can supply hanger products from many companies that sell construction materials. Hanger is prefer very often in many areas. However, in order to determine how many you need, it is useful for the people who will do the necessary work to look at the application area. Before this hanger is supply, it is necessary to look at how many needed.

Drywall profile accessories are quality and very useful. An area where plaster board will made also preferred as accessory materials. In the case of suspended ceilings, there are situations that need to be consider in suspended ceiling processes that will be implement in projects that are newly restore and contain wooden beams. Wood materials can also be prefer as a distributed load and non-spread load gold. In heavy assemblies on the ground, the movements that occur under dynamic loads in wooden bearing systems transmitted to the construction, which is a second sub-carrier. For this reason, it may also be possible to rub metal parts and wood to produce noise.

Suspended Ceiling T Quick Hanger Details

Suspended ceiling T Quick hangers, price, specifications, manufacture, factory, details, where is sold, sale.

Hanging Drywall on Ceilings - Fine Homebuilding

Fine Homebuilding Project Guides

Drywall

How-To

The first rule of drywalling: install ceilings first.

By Myron R. Ferguson

Save your back: When using a lift to install a cathedral ceiling, it’s easiest to hang the first panel at the peak and work your way down to the sidewalls.In a room that will have drywall attached to the ceiling as well as to the walls, always attach the ceiling panels first. By hanging the ceiling first, the panels can be cut a little short so that they slip easily into place. The wall panels, installed later, will fit against the ceiling to help support the edges.

Hanging a ceiling—at least without a mechanical panel lift—is a two-person job. And a third set of hands never hurts. I usually use adjustable step-up benches to hang ceilings that are 9 ft. high or less. I know a few drywall hangers who use stilts when attaching drywall. One crew member on the floor does the cutting and hands the panel to two other crew members on stilts. They in turn lift the panel into place on the ceiling and attach it, cut openings for any electrical boxes, and take the next measurement. Under ideal conditions, working on stilts is the fastest way to hang drywall on ceilings, but I don’t usually use them. The two members on stilts can’t cut and carry panels, which means a lot of work for the person on the floor. In addition, the work area must be kept clean and uncluttered to minimize the risk of falls.

I usually use adjustable step-up benches to hang ceilings that are 9 ft. high or less. I know a few drywall hangers who use stilts when attaching drywall. One crew member on the floor does the cutting and hands the panel to two other crew members on stilts. They in turn lift the panel into place on the ceiling and attach it, cut openings for any electrical boxes, and take the next measurement. Under ideal conditions, working on stilts is the fastest way to hang drywall on ceilings, but I don’t usually use them. The two members on stilts can’t cut and carry panels, which means a lot of work for the person on the floor. In addition, the work area must be kept clean and uncluttered to minimize the risk of falls.

Raising a PanelThough the first few boards can be awkward, two people can do efficient work hanging ceilings without a lift. Start with two step-up benches centered under the section to be hung, and be sure to carry fasteners on your belt.

It’s a balancing act: Support the panel with gentle head pressure as you screw it in place. Alternatively, you can use a T-support to hold the panel in place. |

Prevent Sagging Ceilings

- Fur out the ceiling if on-center spacing is not adequate.

- Use a type of drywall more resistant to sagging.

- Control humidity in the structure before the work begins, while it is being done, and after the installation is complete.

- Prime before texturing. And always let the primer dry thoroughly before texturing.

- Hang the drywall perpendicular to framing.

- Avoid attaching drywall over sagging insulation.

My favorite way to hang high ceilings, especially cathedral ceilings up to 15 ft. high, is to use a mechanical panel lift. This tool does the heavy lifting while I position the panel. And once I’ve aligned the panel, the lift holds it in place while I attach it. It makes your work a little easier, and lifts can be rented from many drywall suppliers and home centers.

And once I’ve aligned the panel, the lift holds it in place while I attach it. It makes your work a little easier, and lifts can be rented from many drywall suppliers and home centers.

| WORK SMART: If you’re hanging a cathedral ceiling without a lift, it’s easier to attach the lower panel first and then work your way up to the top. By starting at the bottom, you’ll have an edge for the next panel to rest on while you hang it. This is easier than trying to lift a panel up to fit against the bottom edge of the panel below it. |

Ceiling panels can be hung perpendicular to the joists or parallel to the joists. I prefer to attach the ceiling panels perpendicular to the joists for a number of reasons:

- Ceiling panels are less likely to sag when hung in this direction (see the sidebar “Grain Orientation in Drywall”).

- It allows the butted seams to be attached to a solid nailer for the length of the seam or floated between the joists.

- It is easier to see the joists when fastening the panels.

- It gives the structure greater strength.

- It won’t matter that much (and may not even be noticed) if the on-center spacing of a ceiling joist is off.

- It allows the drywall to float over slightly uneven joists, making them less conspicuous.

Grain Orientation in DrywallArden Van Norman performed a simple test to prove that drywall is stronger with the grain than across it. He cut one 1-ft. by 4-ft. piece from the end of a panel and one from the side, as shown in the drawing. Stacking bricks in the middle of each piece quickly shows that the end piece is much weaker than the side one. Drywall is approximately three times stronger in the long direction. Accordingly, drywall hung perpendicular to the framing members is stronger than drywall hung parallel, so it is less likely to sag. A simple test proves that drywall is stronger with the grain than across it. |

The only time I hang drywall parallel to the joists is when doing so avoids creating butted seams on the ceiling, or when the method of application affects the fire rating or structural design. Before opting for this method, though, check the spacing of the joists carefully—they must be spaced so that the edge of each panel falls on the center of a joist. If the tapered edges don’t hit on center, you may have to cut the long edge of the panel, which will create a long butted seam. And take care not to create a seam on a joist that is either crowned up or sagged down, as it will be difficult to hide when taping. Also check to make sure the type of drywall you are using is approved for hanging parallel to the joist with the on-center spacing.

No matter the direction in which the panels are hung, if you cannot avoid butted seams, stagger them and keep them as far away as possible from the center of the ceiling. Discontinuous butted seams are easier to conceal and less likely to crack.

Discontinuous butted seams are easier to conceal and less likely to crack.

Before hanging drywall, some ceilings are first furred with 1×3s perpendicular to the joists. A ceiling may be furred for a number of reasons: to help straighten out a wavy ceiling, to decrease the distance between the nailers (ceiling joists), or to provide solid nailing over rigid insulation. The 2-1/2-in.-wide strips make an excellent target when fastening the drywall. The strips should be treated just like ceiling joists, and the drywall should be hung following the same procedures.

Previous: Why You Should Use Screws Instead of Nails for Drywall Next: Hanging Drywall Overhead

Guide

Drywall

Chapter

Hanging Drywall

Drywall

Drywall

Trusted, comprehensive guidance for choosing, hanging, taping, sanding, and repairing drywall—the right way

View Project Guide

View All Project Guides »

Become a member and get unlimited site access, including the Drywall Project Guide.

Start Free Trial

Drywall Basics

- Types and Uses of Drywall

- Planning the Job

Tools and Materials

Hanging Drywall

Taping and Sanding

Special Installations

Drywall Repairs

- Patching Holes, Cracks, and More

Plaster

what are ceiling hangers, how to fix a metal hanger for drywall, rod for suspended and stretch ceilings on hangers

Content:

Adjustable hangers

Varieties of adjustable hangers

Anti-vibration hangers for ceilings

Use of anti-vibration hangers

Hangers PP2

Hangers in the form of brackets

How to fix a ceiling hanger

Fixing non-adjustable hangers

Installation of adjustable hangers

Field of application

Suspension in plasterboard ceiling structures

Video

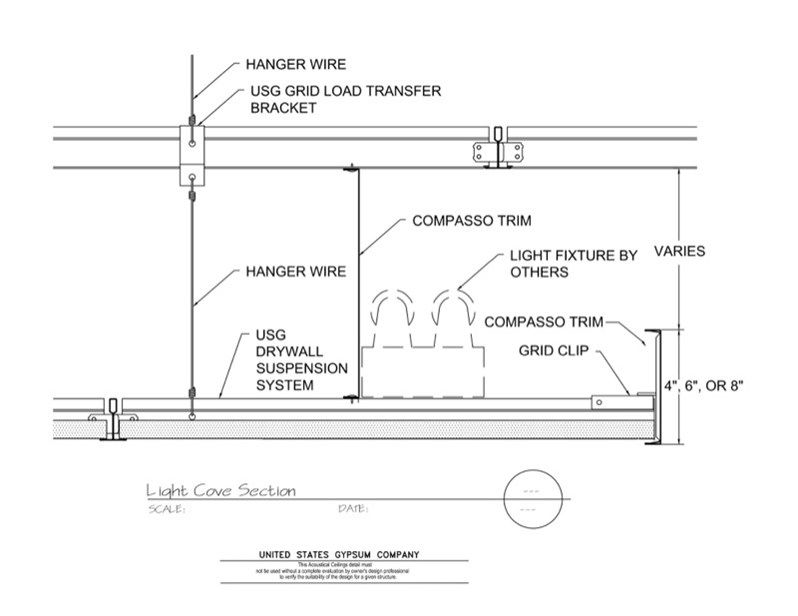

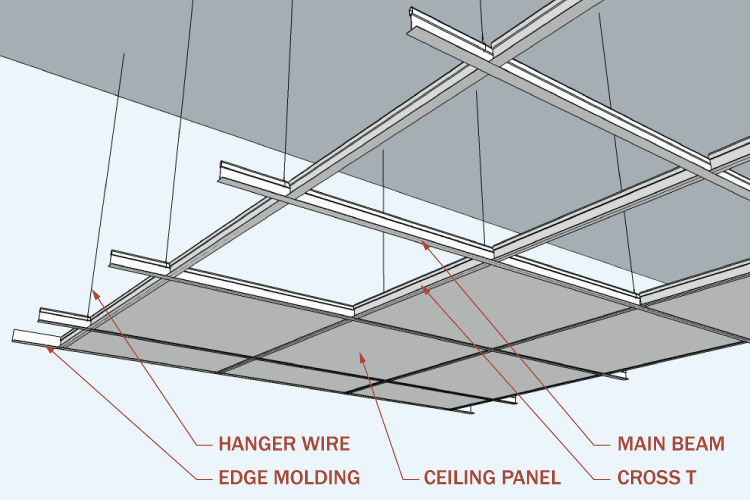

One of the elements of suspended ceiling structures are suspensions. With their help, new, fashionable and maximally new decorative ceilings are created. In addition, when using suspensions, a free space is formed between the main and decorative ceilings, in which thermal insulation and sound insulation, wires of communication systems and ventilation pipes are perfectly masked.

With their help, new, fashionable and maximally new decorative ceilings are created. In addition, when using suspensions, a free space is formed between the main and decorative ceilings, in which thermal insulation and sound insulation, wires of communication systems and ventilation pipes are perfectly masked.

If the height errors of the ceiling surface do not exceed 3 cm, then the use of direct hangers is allowed, with the help of which a minimum distance is created between the ceiling slab and the frame of the hinged system. In all other cases it is recommended to use clamp hangers.

Adjustable hangers

Conventional suspensions are steel wire with a cross section of 3-6 mm. At one end it is tied to the frame of the hinged system, the other end is fixed to the main ceiling. In this case, the distance between the main and false ceiling corresponds to the length of the wire. Such suspensions allow you to choose the level of the false ceiling yourself, based on a design idea or other considerations. nine0003

nine0003

In addition, an independent choice of the length of the wire allows you to adjust the height of the ceiling in different places, this is how curved, sloping and domed ceilings are created.

Types of adjustable hangers

Modern adjustable suspensions are divided into two types:

- Rod or wire hangers are flexible, which limits their use a little. Such elements are used to create suspended ceiling systems in residential premises. nine0039

- Nonius hangers are characterized by rigidity and increased load-bearing characteristics.

Anti-vibration ceiling hangers

Hangers of this type are available in several types, it all depends on the type of supporting structure. There are several features that are inherent in vibration isolating suspensions:

- All parts of the element made of metal are treated with a high-quality anti-corrosion compound and are able to withstand heavy loads.

nine0039

nine0039 - These hangers use a microporous polyurethane elastomer that is specifically designed to dampen vibration and sound vibrations.

- High efficiency is noted when using vibration isolating suspensions in the high and low frequency area, which spring suspensions cannot boast of.

- At 20 Hz and optimum load, vibration is damped by up to 90 percent. In addition, the preservation of vibroacoustic properties for 10 years is noted. nine0039

Use of anti-vibration hangers

The main application of such elements is the installation of soundproof suspension systems.

Hangers PP2

For the manufacture of metal suspensions, galvanized steel with a thickness of 1.5-2 mm is used. However, custom-made pendants may have a different finish. Products are characterized by the ability to withstand loads up to 45 kg. Hangers PP2 are a solid profile made using special sheet-bending equipment. This allows you to perform installation work in a short time, ensuring high quality and reliability of fastening. nine0003

nine0003

Bracket hangers

Tip: Use our construction calculators and you will quickly and accurately calculate building materials.

Direct ceiling hangers for drywall consist of a back and perforated shelves. The suspension is attached to the base surface with the back, the shelves are designed for attaching special plasterboard construction profiles. When using direct hangers, the distance between the main ceiling and the frame of the suspended structure does not exceed 12 cm, which in the case of shortened hangers is reduced to 7.5 cm. nine0003

How to fix the ceiling hanger

All types of hangers, including hangers for stretch ceilings, are designed to fasten the profile to the main ceiling.

Fixing fixed hangers

To fix an unregulated suspension on the ceiling, perform the following steps:

- Before attaching the suspensions to the ceiling, make holes for the anchors, following the markings of the suspension system, and screw the suspension.

nine0039

nine0039 - Bend down the perforated shelves and check the tightness of the fastening by pulling with a little effort.

- Next, place the profile between the hanger legs and unbend them, bringing them to an angle of 90 degrees.

- Using a tensioned cord, fix the level of the frame of the suspension system and drill the profile from both sides. After that, the entire structure is fixed with self-tapping screws. The free edges of the ceiling hanger can be bent to the sides so that they do not interfere with the installation of the sheets. nine0039

Installation of adjustable hangers

Adjustable suspensions are installed according to the following scheme:

- Holes are made in the ceiling for anchors and a special rod for suspended ceiling is fixed to the ceiling.

- The ceiling profile is then inserted into the rails of the opposite walls.

- Suspensions are put on the rods and inserted into the profile.

- By moving the suspension along the rod, you can easily adjust the height of the suspension system. nine0039

- After selecting the desired level, fix the hanger.

Application

In rack ceilings, installation is carried out as follows:

- One side of the hanger is fixed to the main ceiling slab with a dowel-nail.

- The other side is inserted into the frame's special hook hole. Using the expansion plate of the suspension, the stringers are aligned. nine0042

- A spirit level is placed on the ends of two stringers and levelled.

- Similar actions are done at the other ends of the stringers.

- Butterfly - 40 kg.

- Vibro suspension - from 12 to 50 kg.

- Nonius - 40 kg.

- Anchor - 25 kg.

- Straight - 40 kg.

- Frame assembly for wall or ceiling surface finishing.

- The preparatory stage of the frame base for further plasterboard flashing (this option has become the best solution for a room where there are noticeable flaws in the ceiling surface, including a base with bumps, cracks, etc.

).

). - Alignment of all surfaces.

- The lower part is made like a collar, that is, a fastening part with projections. For ease of fastening in the required position for such a part, there are many holes.

- Directly the suspension itself, whose length will be from 0.4 to 1 meter.

- Fixing component in the form of a fastening bracket, due to which the hanger will be fixed in the required position. nine0039

- Conventional hanger.

- Polyurethane vibration suspension with high sound suppression capability.

- Anti-vibration fastener design that looks like a standard anchor.

- The Detachable Vibration Plate is an adjustable design that can accommodate profiles of different lengths.

- Prior to the installation of fasteners, it is required to mark the fastener points on the surface. At the same time, they should be as close as possible to the profile joints, ideally, the distance between wall hangers from drywall sheets should be 0.7 meters. When fixing drywall sheets, it is required that there are small gaps between the drywall sheets of the building material. nine0039

-

To ensure maximum tightness of the guides and guides, a special sealing tape can be glued between them.

- Bearing profiles should not be too close to the surface, and self-tapping caps should not be left lower than the drywall level.

- The simplest method to test the fastener strength of a structure is to pull it with little force.

Learn more

When installing inclined ceilings with the help of suspensions, the desired slope is formed. The work involves the following actions:

Hangers in plasterboard ceilings

Adjustable hangers for drywall frame are used when the ceiling hanger is not long enough or it becomes necessary to install a leveling ceiling. nine0003

nine0003

Such situations most often occur when the distance of the suspended structure from the main ceiling is too large, which is determined by technical or design considerations.

Suspended ceiling on suspensions is mounted using various suspensions, including straight and rod elements, as well as vernier suspensions. Very often, home craftsmen make suspensions of the desired length from profile scraps, bending it with the letter G.

Properly selected suspensions allow you to get a reliable, durable and high-quality design. nine0003

Plasterboard ceiling hangers

Plasterboard ceiling hanger spacing

Plasterboard ceiling installation requires following a number of tips from professionals and important rules. This type of coating for the ceiling surface is incredibly popular with buyers due to its low price and convenient installation.

This type of coating for the ceiling surface is incredibly popular with buyers due to its low price and convenient installation.

But in order for the design to turn out to be at the highest level and to be perfectly even, you only need to know what distance the plasterboard hangers should be on the ceiling. nineOl000

Hangers for ceilings are a universal product, and its functional purpose will be to provide reliable fixation of the plasterboard, perform some decorative functions of coatings. Such components not only help to obtain an ideal, even ceiling surface, but also make the structure particularly stable, durable, soundproof and heat-insulating parameters are noticeably improved, and help in the implementation of the planned design with varying degrees of complexity. nine0003

Details

Distance between hangers on a plasterboard ceiling

When installing plasterboard, it is important to determine in advance how many hangers will be required.

This size will directly depend on the bearing capacity of the element. It is also important to take into account the fact that an ordinary drywall sheet with dimensions of 1.2 * 2.5 meters will have a mass of about 22 kg. According to the declared parameters, various parameters of parts can withstand this type of load:

A suitable amount must be calculated based on the bearing capacity and also the weight of the plasterboard. They should be located at a distance of 0.7 meters from each other. In certain situations, this size can be increased by 0.3 meters, but no more.

Hanger dimensions

Experience shows that choosing the perfect hanger that really fits will largely depend on its size and purpose. The most popular type has become a direct suspension, and it also has a standard size of 1. 25 * 3.6 meters. It should be used in a situation where users want to insulate ceilings or level them. These dimensions are enough to hide the electrical wiring between the ceiling base and the drywall sheet structure. If it becomes necessary to create ceilings with non-standard geometric shapes or you want to install three-dimensional elements (ventilation cabinet), then you need to use a wire rod. The length of the suspension for wire-type GKL is 0.5 and 1 meter. nine0003

25 * 3.6 meters. It should be used in a situation where users want to insulate ceilings or level them. These dimensions are enough to hide the electrical wiring between the ceiling base and the drywall sheet structure. If it becomes necessary to create ceilings with non-standard geometric shapes or you want to install three-dimensional elements (ventilation cabinet), then you need to use a wire rod. The length of the suspension for wire-type GKL is 0.5 and 1 meter. nine0003

Varieties

The building materials market offers an incredible range of suspensions, which differ from each other in technological nuances, shape and methods of fastening. Hangers for drywall sheets in size and variety are very different. Each type of product will have certain features, advantages and disadvantages.

Direct hangers for drywall

The most popular and even common option. According to external data, it is a rectangular plate made of galvanized steel. The main reason for such popularity of suspensions can be considered that due to the small impact of a mechanical nature, it can be changed, which will result in a U-shape. Despite its small size, the galvanized steel element can withstand heavy loads (up to 42 kg). It will not succumb to the aggressive influence of corrosion, and also has a high level of protection against moisture. The usual dimensions of a direct type suspension for drywall sheets are 1.25 * 6.3 meters. Structural parameters make direct suspension on a plasterboard ceiling an indispensable element if it is necessary to install sheets of material to stone, concrete and even brick bases. Due to this, it can be used in rooms with different purposes. nine0003

The main reason for such popularity of suspensions can be considered that due to the small impact of a mechanical nature, it can be changed, which will result in a U-shape. Despite its small size, the galvanized steel element can withstand heavy loads (up to 42 kg). It will not succumb to the aggressive influence of corrosion, and also has a high level of protection against moisture. The usual dimensions of a direct type suspension for drywall sheets are 1.25 * 6.3 meters. Structural parameters make direct suspension on a plasterboard ceiling an indispensable element if it is necessary to install sheets of material to stone, concrete and even brick bases. Due to this, it can be used in rooms with different purposes. nine0003

Quite often, such a suspension is used for:

Let's take a closer look.

Extended hanger

Such a device is used in cases where the metal profile needs to be installed at a distance that exceeds the standard parameters. Quite often, such elements have a length of 0.52 meters, and they are produced exclusively for individual orders. If there is a need for an elongated type profile, it is possible to create it from a direct suspension thanks to simple actions.

Hanger

This variant is also popular under the name "clamp hanger". Its main purpose is the installation of plasterboard structures, fixing suspended ceilings. Anchors make it possible to create the desired ceiling space in terms of dimensions. This will mean that through the use of such a design, buyers will be able to adjust the height of the selected ceiling with their own hands. Height adjustment is made by wire pull. Anchor design includes a rod and a clamp piece. It needs to be installed in the profile, and then everything needs to be fixed in this position by means of a clamp, which is located in the lower structural part. it is extremely important that, unlike direct hangers, the anchor has a lower bearing capacity (no more than 25 kg). nine0003

Anchor design includes a rod and a clamp piece. It needs to be installed in the profile, and then everything needs to be fixed in this position by means of a clamp, which is located in the lower structural part. it is extremely important that, unlike direct hangers, the anchor has a lower bearing capacity (no more than 25 kg). nine0003

Suspension rod

Quite often, when installing a ceiling made of plasterboard sheets, it becomes necessary to change the structural height up to ½ meter. There can be many reasons for this, the most common ones include the need to lay engineering communications, create and finish a duct for ventilation, or install a ceiling with many levels. In this case, it is required to use sliding hangers for drywall sheets, which have become known as an element in the role of a wire structure. The diameter of the suspension will be 0.4 cm. On the one hand, it has a special eye for anchoring to reinforced concrete floors, and on the other hand, a clamp made of galvanized steel. You can adjust the height of the ceiling structure by increasing or decreasing the length of the wire rod. They are produced with the usual length characteristics, and can be of two types - ½ and 1 meter. When changing the structural height of the ceiling, the excess traction must be cut off. nine0003

You can adjust the height of the ceiling structure by increasing or decreasing the length of the wire rod. They are produced with the usual length characteristics, and can be of two types - ½ and 1 meter. When changing the structural height of the ceiling, the excess traction must be cut off. nine0003

Nonius Suspension

A special device that gives the structure an additional degree of rigidity. The vernier hanger is made of the following elements:

Please note that the normal load capacity of the vernier will be 40 kg. When installing, it is required that the distance between the hangers on the plasterboard ceiling is at least 0. 6 meters.

6 meters.

Vibrating hanger

Special adjustable hanger for drywall sheets, which is required to give the structure sound insulation functions. It is not often used when installing plasterboard ceilings. This is explained by its excessively high cost, the ability to muffle extraneous sounds through other methods. As practice has shown, the use of such a device in combination with a seal makes it possible to provide sound insulation to the maximum. nine0003

This type of construction is produced in different variations:

We offer you to look at useful tips from the masters. nine0003

Expert advice

Although the installation is not considered to be an extremely difficult task, not every user can perform the installation work well. Much attention during the installation process must be paid to such criteria as the mass and thickness of the material. According to available information, make a choice of products for fastening. Experts strongly advise you to pay attention to the following points:

Much attention during the installation process must be paid to such criteria as the mass and thickness of the material. According to available information, make a choice of products for fastening. Experts strongly advise you to pay attention to the following points: